Sheet metal forming has become a cornerstone for manufacturing of support components in the field of modern manufacturing. Using just very simple tools yet effective for forming flat sheets of metal into three-dimensional shapes has resolved many problems especially related to mounts. The process is very conventional, but the recent advancements have complimented the concept of batch manufacturing as well. From the fine lines in automotive bodies to the precision required in electronics, sheet metal forming plays a pivotal role in shaping our world. This guide will enhance your knowledge about the working principle of this manufacturing technique along the lines of the whole required process.

The Working Principle of Sheet Metal Forming

The working principle of sheet metal forming follows the simple approach of applying force at an angle or in the form of a shape to form a product. The concept of plastic deformation is mainly employed in this methodology. So basically, all you need is a metal sheet which you can place in a press machine and a die or a tool will then apply a force onto it until plastic deformation to form the required shape. Through a die or a tip, the contours are then formed according to the shape and the finishing surface. The processed part is then sent to the finishing stage where a coating or a layer is applied onto the surface for corrosion prevention.

The Process of Sheet Metal Forming

There are mainly two different categories of sheet metal forming:

Cold Forming: As the name implies, the metal is not heated at a certain temperature for sheet metal forming because it is bound to retain it’s ductility at room temperature. This process is relatively more energy efficient but can cause complications in forming.

Hot Forming: So in this category, you have to pre-heat the metal plate to a temperature where it surpasses the recrystallization point and then forming is done. In this case, the malleability of the metal is enhanced allowing you to form metals into complex geometries.

Common Techniques in Sheet Metal Forming

As explained earlier, there are multiple techniques by which sheet metal forming is done, some of them are:

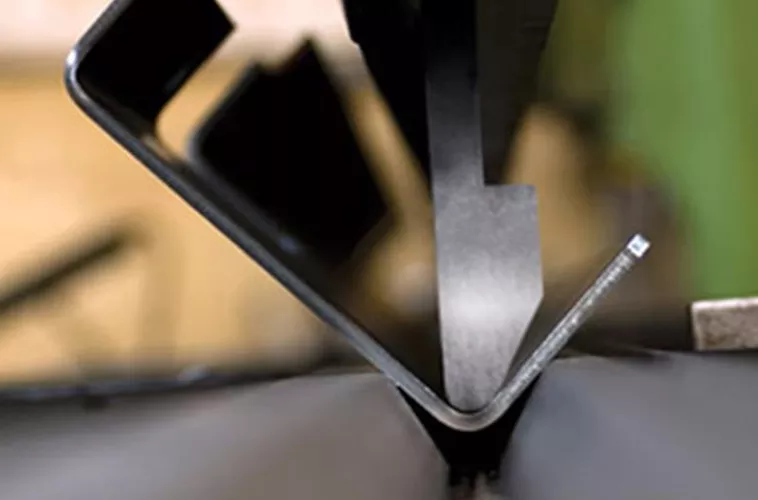

Bending: For this technique, the deformation is done along a straight axis around which angles and curves are produced. This process is done using a specialized bending machine.

Drawing: In this process, metal sheet is drawn into a cavity shaped die such as a cup or tube that is of the required shape. This process requires manufacturing of the die as well.

Stamping: In the automotive industry mainly, you’ll find complex components and they are formed using this technique via a stamp and the sheet is cut into the required shape at different angles.

Rolling: In this process, the thickness of the sheet is altered to a certain radius or diameter.

The Use of Sheet Metal Forming

There are diverse industrial applications of sheet metal forming that are spread across various industries. Some of the major industries are listed below:

Automotive Industry: In the automotive industry, sheet metal is mainly used for car body manufacturing and other secondary parts.

Aerospace Industry: Similar to automotives, airplane wings and fuselage are manufactured using sheet metal forming.

Construction Industry: Some essential building components are manufactured such as roofing, windows and shades using this technique.

Electronics Industry: They are mainly used for manufacturing encasements, closures for electrical equipment.

Advancements and Innovations in Sheet Metal Forming

As technology has advanced in most of the industries, sheet metal forming is likely to be shaped by advancements as well. Some complimentary manufacturing techniques such as 3D printing or additive manufacturing add to the value of sheet metal forming. This offers more possibilities for more complex geometries as they provide more value to the application in various industries. Real-time monitoring and application of automation techniques have yielded efficient results for bulk production. Some of the key advancements in sheet metal forming are briefly summarized below:

Automation:

One big change is the use of automation in the forming process, many computer programs like CAD and CAM. These programs help engineers design complex sheet metal parts more accurately. These advancements have developed the capability of industries to engage in bulk manufacturing.

Decreasing Human-Intervention:

The use of robots have improved the overall manufacturing process because less human intervention in bulk production can yield better results. For example, if symmetrical components are to be manufactured then it’s best to automate the machinery in a way that the end-product is of the required shape and size.

High-strength Alloys and Composites:

The use of high-strength alloys and composites have also improved the forming process. Most of the times, the physical and mechanical properties are enhanced which is why they are much easier for metal forming.

Challenges and Future Directions in Sheet Metal Forming

There are continuous challenges a manufacturer faces in sheet metal forming, some of these challenges are:

Springback:

One of the major issues that often sheet metal forming manufacturers face is the phenomenon of springback. This often happens when the sheet is not bent upto the plastic deformation stage which results in the sheet going back to its original shape that can cause deformities in the finalized stage.

Sustainability:

Sustainability is something that is very important in the current era and with the industrialization taking a newer approach. Sheet metal forming techniques often result in wastage and they can be a blocker especially in the wider context of the whole industry.

Conclusion

Sheet metal forming is a demonstration of human creativity, combining creativity and design to shape our environment. It’s crucial for those involved in design, planning, or production to understand the complex activities, processes, and applications of sheet metal forming. This understanding leads to innovative and durable products that define our modern world. The challenges faced for manufacturers during sheet metal forming can be evaded by the use of technology. Sheet metal forming offers manufacturers a range of possibilities, driving advancement and progress across industries. So all in all, incorporating modern tools is important for the manufacturing technique to be self-sustained.