Online Waterjet Cutting Service

We don’t have minimums, we deliver the best parts for your money, and meet your deadlines!Instant Quotes and Cost-effective, On-demand Fabrication.Every job is unique, and many require special considerations for materials, finishing, custom work, or urgent delivery – your commercial quote will be turned around by seasoned estimators who confirm all aspects of your job.

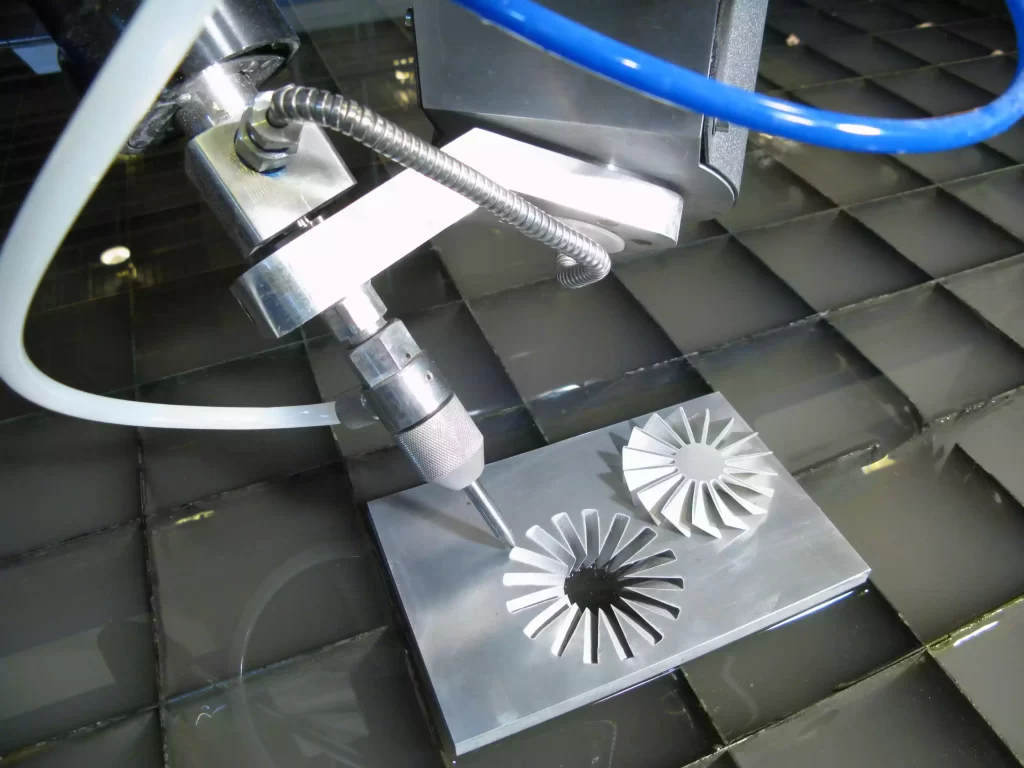

Precision Waterjet Cutting

When you need to cut precision metal parts with high precision, waterjet cutting is a versatile and cost-effective solution. Metalworking experts use waterjet cutting to cut custom metal parts with high precision. This is a cold cutting technique that uses water (or a mixture of water and an abrasive, such as garnet) to cut materials through rapid erosion. Unlike laser cutters or plasma cutters, waterjet cutting tools do not rely on thermal mechanisms; instead, they spray water at three times the speed of sound. The pressurized water flow amplifies the erosional effects to produce the necessary cuts in the material quickly and cleanly.

Positioning accuracy is + or – .001. We can actively adjust the angle of the water jet so that all of the taper is toward the waste edge of the part. The machine features automatic height control, which means the spacing to the material is consistent, allowing for optimal nozzle positioning above the material. The result is a very good surface with virtually no streaks, allowing net shape manufacturing or rapid finishing of near net shape (NSS) blanks. The waterjet can process boards up to 6 feet by 12 feet and up to 8 inches thick.

Order online your custom waterjet cut parts in just a few steps

You can get instant quotes from 3D CAD files or DXF files in our instant quote engine. Rapid Manufacture utilizes cutting-edge waterjet machining technology and a team of highly skilled professionals to ensure your parts are cut with exceptional precision and flawless results. quality. Follow these steps to order parts easily:

Create or upload your CAD file – Use our instant quote engine to upload your CAD file and get an analysis of your part along with an instant quote.

Configure your part – choose from over 50 materials and finishes. Enter the quantity, address, and any special comments for the mechanic.

Receive Quote – Get a quote for your design.

Order Your Parts – Place your order and receive quality CNC parts!

Why Choose Rapid Manufacture for Waterjet Cutting?

Quick turnaround

We’re committed to reducing friction at every stage, so you can be as delighted with the speed of your Sheet Metal parts’ arrival as you are with their exceptional quality.

Unparalleled scalability

Whether you’re after a one-off prototype or 10,000 units at the most competitive price, Waterjet Cutting is a fantastic and cost-effective method of production.

Perfect Finish

We offer high-quality finishing processes for most Waterjet Cut parts; from polishing and plating to powder coating and more.

Order Any Size

With cutting areas of up to 6000 x 2000mm, and presses up to 80T, we’ll help you with the Sheet Metal Fabrication of both small components and larger Sheet Metal parts.

A Wide Variety Of Materials

We offer most gauges of steels, copper, aluminium and more, and take great care to ensure the right material is used for every waterjet cut part.

A Wide Range Of Industries

From enclosures and brackets to frames and chassis, we’re proud to create beautiful Waterjet Cut parts for any and every industry.

Waterjet Cutter General Tolerances

| Description | General Tolerance |

|---|---|

Distance Dimensions | For full details on tolerances offered by Rapid Manufacture’s sheet cutting service, including edge to edge tolerance and taper, please consult our manufacturing standards. |

Thickness Dimension | Thickness tolerances are determined by the material blank. |

Minimum Recommend Part Size | 3.000″ |

Minimum Feature Size | 2X material thickness with a minimum of 0.125″ |

Kerf (slit size) | Approximately 0.062″ |

Edge Condition | Waterjet parts will have a vertical striation on the edges and may show a slight taper. |

What is Waterjet Cutting?

It is another way of cutting materials, including metals. The main difference between waterjet cutting and other cutting methods is that it is a non-thermal process. Non-thermal means it does not use heat. It is rather a mechanical process where material is removed by physical contact and material wear.

Cutting with water is possible because of the waterjet’s speed. It’s supersonic, meaning it comes out of the nozzle at a quicker speed than sound travels. But water alone could not cut such a wide range of materials. Therefore, abrasives are added to the mix. The abrasive material is usually crushed garnet. You may recall it as the stone that makes sandpaper rough.

Using high pressures, the abrasives hit the material at a great speed. This erodes away the metal bit by bit. The pressure for waterjet cutting is usually around 380 MPa but newer systems use pressures up to 620 MPa.

As the material removal is gradual, the temperatures cannot rise high. And any possibility of this happening is eliminated by the use of water. The waterjet is straight throughout its path, providing a straight cut along the material thickness.

Waterjet Cutting Materials

Rapid Manufacture offers a comprehensive selection of waterjet materials in various thicknesses for cutting.

- Metals alloys, up to 1″ thick

- Mechanical plastic

- Acrylic (Plexiglass)

- Foam

- Rubber and Gasketing

- Wood and MDF

- Carbon Fiber Composite

Benefits of Waterjet Cutting

Compared to other cutting methods, waterjet cutting offers numerous benefits, including:

- No heat affected zone: As mentioned previously, waterjet cutting is a cold-cutting technique that does not require material to be heated or stressed with machinery. This lack of thermal input means that there is little to no heat affected zone (HAZ) — which decreases the risk of thermal distortion, such as warping or impurities in certain materials.

- Versatility: Waterjet cutting can be used on a wide range of materials, including glass, paper, metal, foods, composites, mixed materials, and more.

- Tight tolerance: Waterjet cutting can cut parts with better tolerances, especially on thicker materials.

- Reduced slag: Since waterjet cutting leverages water and recyclable abrasives, you do not have to deal with slag byproducts that can be produced by other cutting methods, such as laser cutting or plasma cutting.

- Ultra-fine finish: Waterjet cutting produces a fine sand-blasted edge finish, which can sometimes eliminate the need for finishing services.

Who Can Use Waterjet Cutting Services?

Machine Shops: Allow us to precut your parts. We can hog out large or small parts with no heat affected zones. This will allow you to more tightly nest your waterjet parts in your mill, save milling time, save wear and tear on your machine, and save milling bits and other consumables.

Sign Companies: We can cut you letters, marquees, banners or other artistic projects your customers want. We can waterjet cut virtually any size and font you can imagine. Allowing us to cut out your letters and marquees can free up your valuable resources for assembly and installation. We can custom cut any font in aluminum, stainless, or any other material you want.

Metal Fabricators: We can waterjet cut virtually any material up to six inches thick, and with tolerances of up to +/- .005”. Our waterjet machining can pre-cut your parts with minimum burr and no heat affected zones.

Manufacturing and Fabrication shops: Allow us to pre-fabricate your parts, prior to your final process. Or, we can create your final product.

Artistic Designers: If you can imagine it, we can cut it! We would love to help you create those artistic masterpieces. We can custom waterjet cut virtually any material in any shape. Metal art is no problem for our waterjet. We can cut virtually any artistic design, from any material.

Metal Stamping and Tool Die Makers: Eliminate tooling costs on short run parts by having cut with our precision waterjet cutting applications. Hard to stamp materials are no problem for our waterjet shop.

Torched or Burned parts: Have a part that is too thick for plasma or laser cutting? We can waterjet cut that part and there will be no heat affected zones and no secondary clean up.

Construction Contractors: We can custom cut your metal artistic design with quality and precision.

Auto, Motorcycle, ATV Enthusiasts, and other Hobbyists: We are right there with you!! Sometimes you just need that one special thing made! E-mail, call or stop by. Well help you out! If we can’t do it, we’ll help you find someone that can!

Start your first waterjet cutting project today!

Upload your CAD design to our instant quote engine and get a free instant quote on custom waterjet cut parts. .