Tube Bending Services

Rapid Manufacture offers tube bending and tube fabrication services for metallic pipe and tube stock to meet your needs.

Tube Bending Company in China

As a full-service metal manufacturer, Rapid Manufacture offers a comprehensive range of solutions for improving your processes and increasing profitability. If you’re searching for a reliable source for tube bending, tube forming and pipe cutting in china, we’re the one-stop shop for everything you require. We eliminate timely and costly steps from the supply chain while delivering quality tubular parts and products that fit your particular requirements. No matter the scale of your tube bending project, Rapid Manufacture manufacturing is ready to assist you.

Tube Bending Services Online Quote

Rapid Manufacture’s instant quote engine allows us to get started on a project quickly and directly. You simply upload a supported 3D CAD file and a drawing that defines specific requirements (such as centerline radius, tube profile, etc.) to get started. You can specify pipe bending as your requirement using the simple drop-down menu in the quote interface. Manufacturing process and define your quantity requirements, required materials, finishes, etc.

Our project managers and experts personally review and manually quote each pipe bending project to ensure we meet your unique needs while providing a fast, easy manufacturing experience. Review our capabilities in the following sections to learn more about different tube bending machines and technologies.

Applications for Tube Bending Services

Musical instruments, sculptures, custom bicycle frames; there is no limit to the uses for bent pipe. Rapid Manufacture has been serving a diverse client base representing various types of industries. Some application examples of our structural pipe and pipe bending services include:

- Elbows and u-joints

- Handrails

- Bike racks

- Chassis components

- Axles for lawnmowers and other pieces of equipment

- Fences

- Gates

- Furniture frames

- Marine rails

- Roll cages

- Exhaust pipes

- Large pipes for power plants, oil and gas pipelines and freeway signs

What is Tube Bending process?

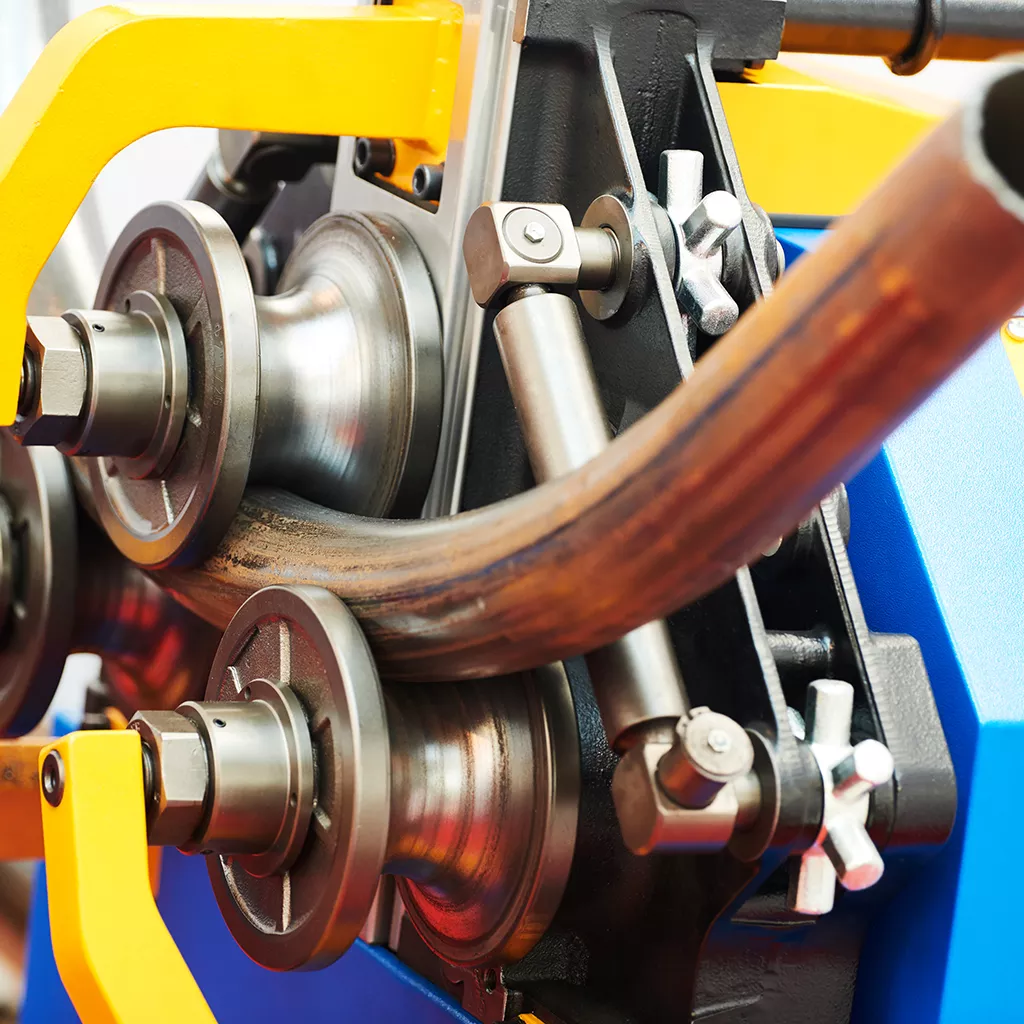

Tube bending consists of a series of manufacturing processes that alter the shape of a pipe or tube to create the desired geometry or features that meet specific requirements. In the process, tube stock is loaded into a bending machine which uses mechanical forces to push the tube against dies and rollers that cause the tube to conform to a shape. Tubes can be bent two-dimensionally where the openings remain on the same plane or in three dimensions where they sit on different planes.

The specific process of CNC Tube Bending processing

here’s an example of the CNC tube bending process on an electric/hydraulic CNC tube bending machine (a common choice for CNC bending):

- The metal tube is sized and it receives a clean, dry cut (no oils).

- The cut piece of tube is inserted into the bender’s mandrel and is clamped down.

- The CNC tube bender operator loads the program that includes the part number that informs the bending machine of the proper bend.

- The CNC operator presses a foot pedal to begin the process (which is part of the safety features of a bender).

- The tube bends in less than one minute using the sheer force of the bender.

Tube Bending Material Options

Various materials respond differently to bending, even when technicians use the same equipment and methodology. Because the process stretches materials to some degree, flexible metals usually work best.

| Material | Round Tube | Pipe | Rectangular Tube | Square Tube |

|---|---|---|---|---|

|

Aluminum |

|

|

|

|

|

Steel |

|

|

|

|

|

Stainless Steel Tubes |

|

|

|

|

|

Brass |

|

|

|

|

|

Copper |

|

|||

|

Titanium |

|

Bend Requirements

Rapid Manufacture can support a wide variety of bend requirements–certain parameters are helpful when building a quote, including the following specifications:

- Center line radius

- Bend radii

- Tube profile (round, square, etc.)

- Tube wall thickness

- Tube diameter (based on schedule or wall thickness)

- Type of bend (‘L bend’, ‘U bend’, ‘S bend’, ‘Coil bend’, or a combination of bends)

- Project volume (can handle thousands of pieces)

Tube and Pipe End Finishing Services

Rapid Manufacture offers finishing options for tube and pipe ends to address all of your product needs. Among the options available are the following:

- Reducing or expanding end sizes

- Beveling

- Chamfering

- Facing

- Flanging

- Flaring

- Flattening

- Swaging

- Reaming

- Bead creation

- Roll Grooving

Industries Served

Tube bending can be utilized across a diverse set of industries. From architectural and lighting fixtures in buildings to vehicle exhaust systems. Below is a list of just some of the notable sectors our tube fabrication and bending services are an ideal fit for:

- Aerospace

- Medical & Pharmaceutical

- Architectural & Lighting

- Automotive

- Oil & Gas

- Aviation

- Marine & Shipbuilding

- Construction

Benefits of CNC Tube Bending

CNC tube bending provides a more precise, automatic, and repeatable process than manual tube bending. Compared with manual bending, CNC tube bending machines can accurately control the degree of a bend, the distances between bends, and the plane of the bend. CNC tube bending allows for maximum accuracy due to its higher degree of control within the process. This computerized and automated tube bending process makes it possible to perform more complex bending processes than manual bending, and increases overall operational efficiency.

Additional benefits include:

- Using a CNC bending machine, welds, joints and expensive fixtures are eliminated from a complex assembly system.

- CNC bending is a cleaner option compared to other bending/welding processes.

- Projects are generally less expensive as fewer fittings equals a lower overall cost. If you can eliminate five fittings from each of your 10 systems, you can effectively eliminate the cost of 50 fittings.

- Eliminating welds and joints within a system also eliminates the risk of leaks that may occur in welded or jointed complex assembly systems.

- The semiconductor industry benefits from building systems without the wall thinning that can occur in welded systems. With CNC tube bending, the integrity of the materials is maintained.

- CNC tube bending also produces a much smoother finish than other processes. Depending on how the system is being implemented, an engineer may prefer a system that looks better cosmetically.

- Fewer bends in a system minimize flow restrictions for chemicals and liquids that may otherwise get trapped in joints or sharp corners.

- Precision tube pipe systems are produced faster and more precisely on CNC bending machines, allowing time savings of up to 95 percent.

Ready to start your tube bending quote?

Rapid Manufacture is a full-service, one-stop shop offering metal products manufactured to customer specifications, the industry’s best precision bends and metal fabrication from small to large diameters with the tightest tolerances to meet any requirement.