Stereolithography (SLA) 3D Printing Service

vastly popular for its ability to produce high-accuracy, isotropic, and watertight prototypes and parts in a range of advanced materials with fine features and smooth surface finish. SLA 3D printing service for rapid prototyping. Get an instant online quote.

SLA 3D Printing Service in China

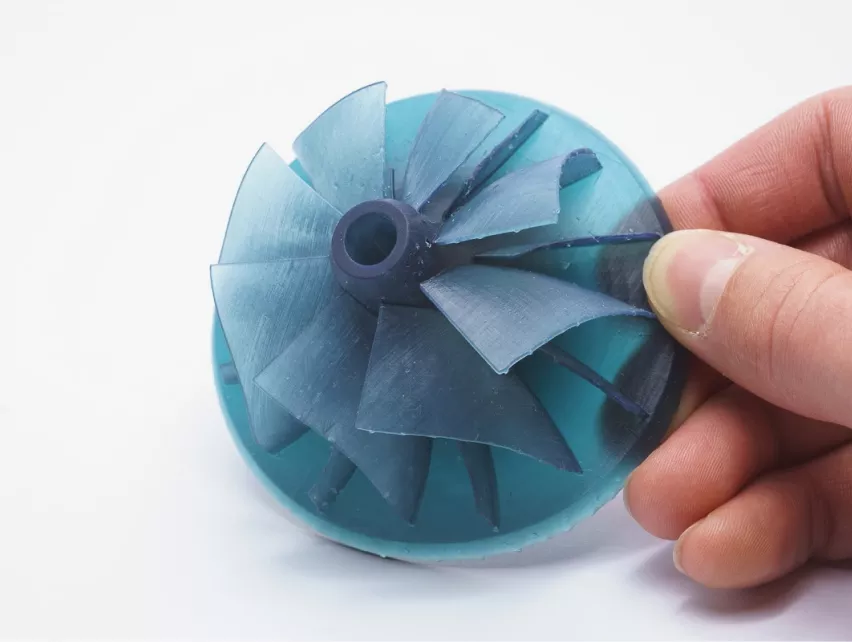

If you’re looking for a fast, low-cost way to produce presentation models or test the fit and finish of prototype parts, stereolithography (SLA) is an ideal solution.Rapid Manufacture is a globally certified SLA 3D printing service provider. We can provide high-quality Stereolithography(SLA) 3D printing services. Stereolithography (SLA) is a powerful 3D printing technology that produces extremely accurate and high-resolution parts that are capable of being used directly in end-use, low-volume production, or rapid prototyping. It offers higher resolution printing than many other 3D printing technologies, allowing customers to print parts with fine details and surface finishes.

SLA 3D Printing Service Online Quote

Are you looking for the perfect manufacturer? Rapid Manufacture provides the best online 3D printing services for your resin parts. Using our smart online quoting system, you can choose from multiple options, receive an immediate quote, and let us handle the manufacturing at our ISO 9001 certified facility. Upload your 3D file to get a quote now.

How our SLA solutions can help you

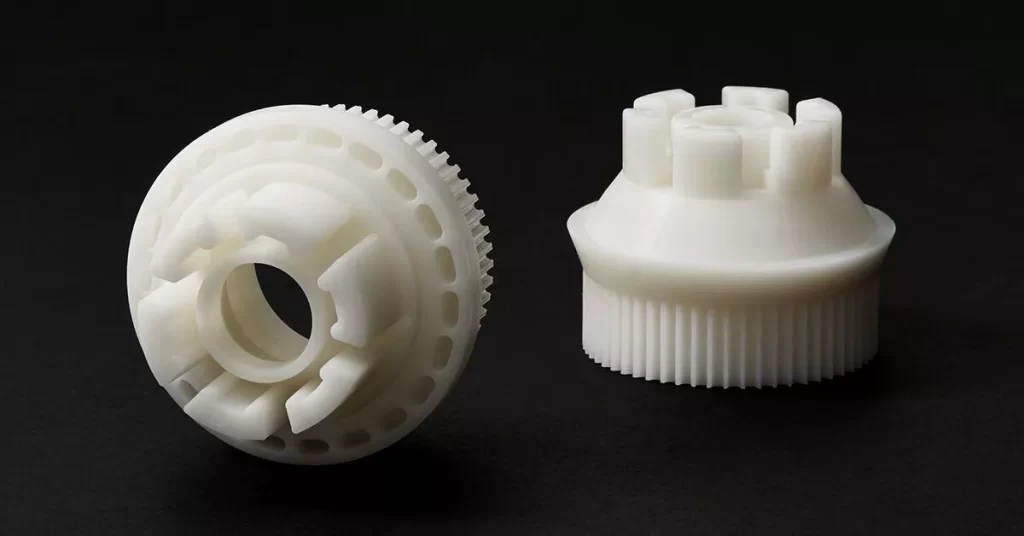

- Produce high precision, quality 3D models with fine details and complex geometries faster and more cost-effectively.

- Accelerate design processes for just about any part: form/fit models, mechanical models, master patterns for cast urethane, etc.

- Create quality surface finishes using a variety of paints and textures for highly-cosmetic show models.

- Eliminate the need for hazardous filaments and powders for more eco-friendly additive manufacturing.

SLA General Tolerances

| Description | Standard Resolution | High Resolution |

|---|---|---|

|

Build envelope |

29” x 25” x 21” |

10” x 10” x 10” |

|

Layer height |

0.004″ |

0.002″ |

|

Tolerance, XY Plane |

+/- 0.005” for the first inch is typical, plus +/- 0.002” for every inch thereafter. |

+/- 0.005” for the first inch is typical, plus +/- 0.002” for every inch thereafter. |

|

Tolerance, Z Plane |

+/- 0.010” for the first inch is typical, plus +/- 0.002” for every inch thereafter. |

+/- 0.010” for the first inch is typical, plus +/- 0.002” for every inch thereafter. |

|

Minimum linear feature size |

Under 0.030” are at risk and under 0.020” will not build. |

Under 0.020” are at risk and under 0.010” will not build. |

|

Minimum radial feature size |

0.035″ |

0.030″ |

SLA Material Options

ABS-Like White (Accura Xtreme White 200) is a widely used general purpose SLA material. In terms of flexibility and strength, this material falls between molded polypropylene and molded ABS, which makes it a good choice for functional prototypes. Parts as large as 29 in. x 25 in. x 21 in. can be built with ABS-Like White so consider it a primary option if you require an extensive part size build envelope.

ABS-Like Gray (Accura Xtreme Gray) is a widely used general purpose SLA material. In terms of flexibility and strength, this material falls between molded polypropylene and molded ABS, which makes it a good choice for functional prototypes. ABS-Like Gray offers the highest HDT of the ABS-like SLA resins.

ABS-Like Black (Accura 7820) is a widely used general purpose material. Its deep black color and glossy up-facing surfaces in a top profile offer the appearance of a molded part, while layer lines may be visible in a side profile. RenShape 7820 also has low moisture absorption (0.25% per ASTM D570) so that parts are more dimensionally stable. Compared to other SLA materials, it has midrange values for all mechanical properties.

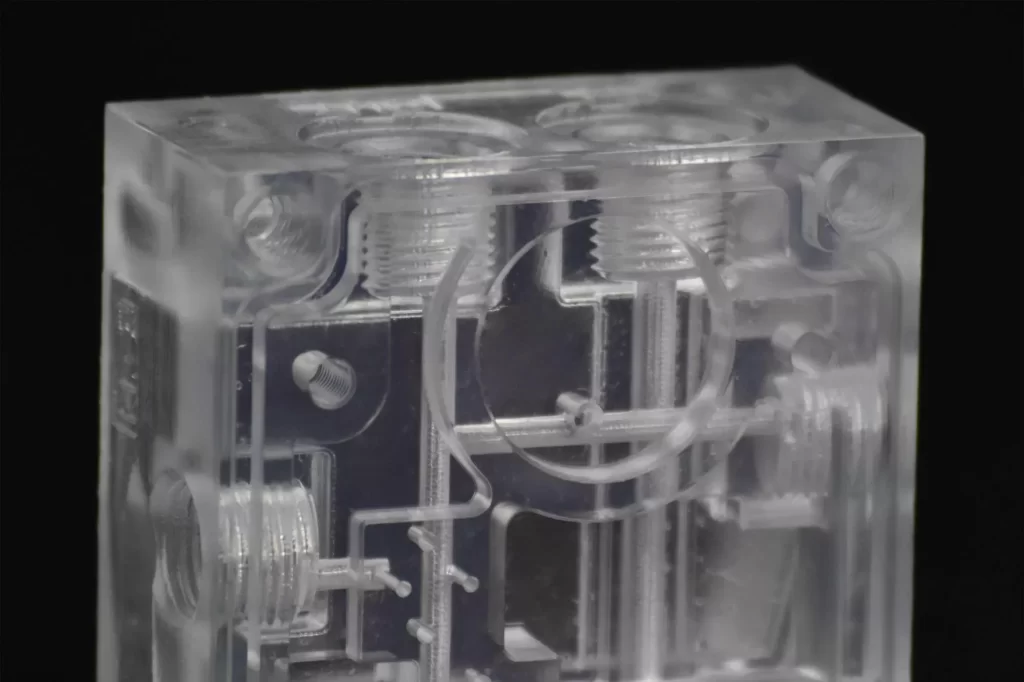

ABS-Like Translucent/Clear (WaterShed XC 11122) offers a unique combination of low moisture absorption (0.35% 0.25% per ASTM D570) and near-colorless transparency. Secondary operations are required to achieve functional part clarity, and the part will also retain a very light blue hue afterward. While good for general-purpose applications, WaterShed is the best choice for flow-visualization models, light pipes, and lenses.

MicroFine™ is a custom formulated material available in gray and green that is exclusive to Protolabs. This ABS-like thermoset is printed in Protolabs’ customized machinery to achieve high resolution features as small as 0.002 in. MicroFine is ideal for small parts, generally less than 1 in. by 1 in. by 1 in. In terms of mechanical properties, MicroFine falls in the mid-range of SLA materials for tensile strength and modulus and on the low end for impact strength and elongation.

PP-Like Translucent White (Somos 9120) is the most flexible SLA option outside of Carbon RPU 70 and FPU 50. In direct comparison to the average values of an injection-molded polypropylene, 9120 has similar tensile strength, tensile modulus, flexural modulus, and impact strength. The only departure from molded PP is its elongation value, which is only 25% of the molded thermoplastic.

PC-Like Advanced High Temp (Accura 5530) creates strong, stiff parts with high temperature resistance. A thermal post-cure option can increase HDT as high as 482°F at 0.46 MPa loading. Accura 5530 has the highest E-modulus of all the unfilled SLA materials, and it is known for being resistant to automotive fluids. However, the thermal curing process does make Accura 5530 less durable, resulting in a 50% reduction to elongation.

PC-Like Translucent/Clear (Accura 60) is an alternative to the general purpose ABS-like materials and WaterShed XC 11122 when stiffness is desired. Like WaterShed, this material can be custom finished to achieve functional transparency with secondary processing. Accura 60 has the highest tensile strength of and elastic modulus compared of all SLA materials outside of the Advanced High Temp options that are most often thermal cured.

Ceramic-Like Advanced HighTemp (PerFORM) exhibits the highest tensile strength and E-modulus making it the stiffest performance material of the SLA materials. When the thermal cure option is applied to parts made from PerFORM, it exhibits the highest HDT (as high as 514°F at 0.46 MPa loading) of the SLA materials.

True silicone is 100% pure silicone that is available in different shore-A hardness as detailed below. The material is suitable to produce both functional prototypes and end-use products. The material shows high resistance to harsh environments conditions, various acids, bases and nonpolar solvents.

Available SLA finishes

Supported surfaces will be lightly sanded with 220 or 320 grit sandpaper, then media blasted for a uniform matte finish.

Supported surfaces will be lightly sanded with 220 or 320 grit sandpaper for improved surface quality. Sanding scratches will be visible on supported surfaces.

Supported areas may show small grid-like dots or surface blemishes as a result of support removal.

Available for Accura ClearVue. Only supported surfaces are sanded. Parts will still have visible layering. High gloss clear coat is applied to enhance natural clarity.

Rapid Manufacture provides additional SLA finishing options, including but not limited to sanding, polishing, painting, post thermal processing, and plating to meet your needs.

Benefits of SLA 3D printing

Simplifies complex processes

Some 3D-printing methods produce rough builds and require postproduction processing to improve the surface finish. Therefore, those methods are often only used for size or dimensional testing. Stereolithography, however, lets manufacturers build finer finishes into their complex-geometry print designs, minimizing post-processing steps.

Reduces post-manufacture work

Other 3D-printing methods produce variations in their layers that result in rough or rutted surfaces, but stereolithography has isotropy, or uniformity, between its layers due to how new layers bond to the cured layers. This uniformity results in minimal variation between layers, making SLA one of the few single-state additive production processes, resulting in less post-manufacture cleaning or polishing.

Enables on-demand flexibility

Stereolithography 3D printers can use multiple resin tanks, which means manufacturers can print objects with different colors or slightly different materials in one pass. This can create a toy that’s ready for play or print areas of varying flexibility in a single structure.

What is SLA 3D Printing & Stereolithography?

Stereolithography (SLA) also often referred to as SLA is the most widely used resin 3D printing technology and it is generally considered to provide the greatest accuracy and best surface finish of any prototyping or 3D printing process.

Stereolithography is an industrial 3D printing process used to create concept models, complex or even very intricate parts. It is a popular choice as many parts can be built in just a day! With Rapid Manufacture’s secondary finishing services such as painting and finishing we can make your part and the details within it really stand out.

An overview of the SLA 3D printing process

Stereolithography (SLA) is an epoxy-based photopolymer system that utilizes lasers to cure the resin on the cross-sectional area of the part. It begins with a recoating bar that applies a thin layer of resin, then an ultraviolet laser creates an image of the part on that resin. After one layer, this process is repeated until the build is complete.

Once the build is complete, the parts are removed and put into a solvent to remove excess resin. The SLA process uses supports of the same material as the part itself, which have to be manually removed. From there, the parts go through a curing cycle in a UV curing machine.

High Speed SLA Design Guidelines

Please note that these are are guidelines, not hard-and-fast rules. Follow these, and you should be in pretty good shape. We’ll let you know if we see any problems with your design.

| Parameter | Inches | Milimeters |

| Minimum Supported Wall Thickness | 0.030 | 0.75 |

| Minimum Unsupported Wall Thickness | 0.040 | 1.00 |

| Minimum Supported Bosses | 0.030 | 0.75 |

| Minimum Unsupported Bosses | 0.040 | 1.00 |

| Minimum Embossed Detail (Height and Width) | 0.010 | 0.25 |

| Minimum Engraved Detail (Height and Width) | 0.010 | 0.25 |

| Clearance | 0.010 | 0.25 |

Upload your design to get a free instant quote

An experienced engineer will help you first determine if SLA is the right solution and will guide you to optimize your part design for the best results.Get a quote on your SLA project today with our Online quote platform.