Rapid Prototyping Service

Online rapid prototyping services are game-changers for engineers who need to iterate their product designs quickly and cost-effectively.

Rapid Prototype Manufacturing

VISIT OUR FACTORY

Complete Prototyping & Manufacturing Capabilities

Watch our video to learn more about how we Rapid Manufacturing support on demand parts production and custom manufacturing for you.

From Design to Prototyping to Production

We are always ready to turn your ideas into reality and provide advanced manufacturing solutions suitable for your products.

Focusing On Our Rapid Prototyping Services

We let you test out a full range of materials and finishes, so you can make an informed decision on how to take your project forward.

We have an array of rapid prototyping processes for you to choose from.

Let's Start A New Project Today

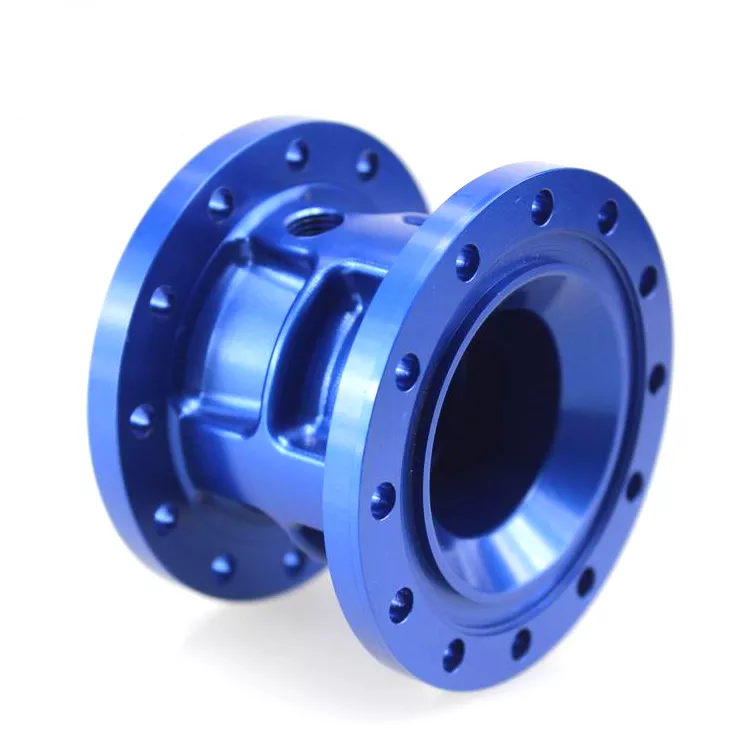

Rapid 3D printing, CNC machining, sheet metal, and injection molding. Parts ship in days.

Our Rapid Prototyping for Various Industrial Applications

Many industries, such as medical and food, rely on Rapid Manufacture’s rapid prototyping capabilities

to meet their growing demand for parts used on critical production equipment.

Industrial

Image Accordion Content Goes Here! Click edit button to change this text.

Choose between rapid prototyping processes

For engineers and product designers looking for rapid prototyping online services to speed up their product development cycles, Rapid Manufacture offers a variety of rapid manufacturing processes that can be used to create prototypes quickly and affordably.

Although there are countless ways to produce any single prototype, it is ultimately up to engineers to decide which processes and materials are best for their product.

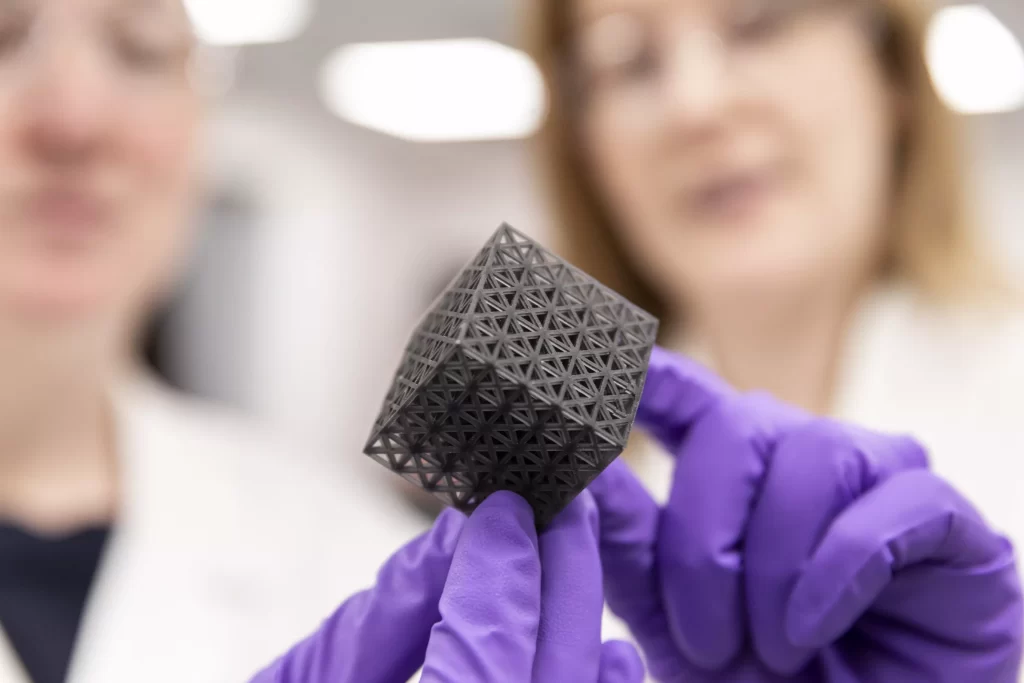

In recent years, advances in additive manufacturing have made 3D printing the first choice for engineers looking for rapid prototyping solutions: parts can be printed quickly and cheaply in a variety of different metals and plastics.

Instant Quotation and Automated DFM Analysis

Rapid Manufacture’s rapid prototyping services can meet your needs from prototyping to volume manufacturing. Through our extensive network of in-house manufacturing facilities and with the help of our new and advanced quoting platform, you can get quotes and DFM analysis instantly.

From pricing to design feedback to status updates, our lightning-fast quoting engine makes custom parts sourcing easy and hassle-free.

Rapid prototyping is a product development method that utilizes turnkey manufacturing techniques to quickly produce multiple iterations of a component for testing and evaluation. It’s a way to get parts ready for hands-on review as quickly as possible.

Because of its affordability and short turnaround time, 3D printing is the technology most often chosen for rapid prototyping. In addition to 3D printing, other common rapid prototyping processes include CNC machining, sheet metal fabrication, and rapid injection molding.

Speed and economy are key principles of rapid prototyping, allowing multiple designs to be prototyped simultaneously, or a prototype to be modified and remade in rapid succession.

These prototypes provide critical information that helps engineers make design decisions before moving to higher-fidelity models for functional testing and production.

Rapid prototyping services can be used to test a variety of designs and materials as the usual financial and time risks are eliminated.

This mitigates the risk of moving forward with a project without sufficient information.

Rapid prototyping is a product development method that allows the production and iteration of product parts for evaluation and testing.

By manufacturing your rapid prototypes with RAPIDmanufacture guarantees, you make the best decision regarding your design.

We are your reliable R&D partner. From a CAD design to a physical prototype in your hands, and finally to your team, it is faster than ever. We have developed the latest rapid prototyping technology to meet your design challenges, and will work with you to verify and improve your product ideas, functional testing, and engineering verification.

Our rapid prototyping services include CNC prototyping, 3D printing, vacuum casting, rapid tooling, sheet metal prototyping, and prototype finishing.