PolyJet 3D Printing Service

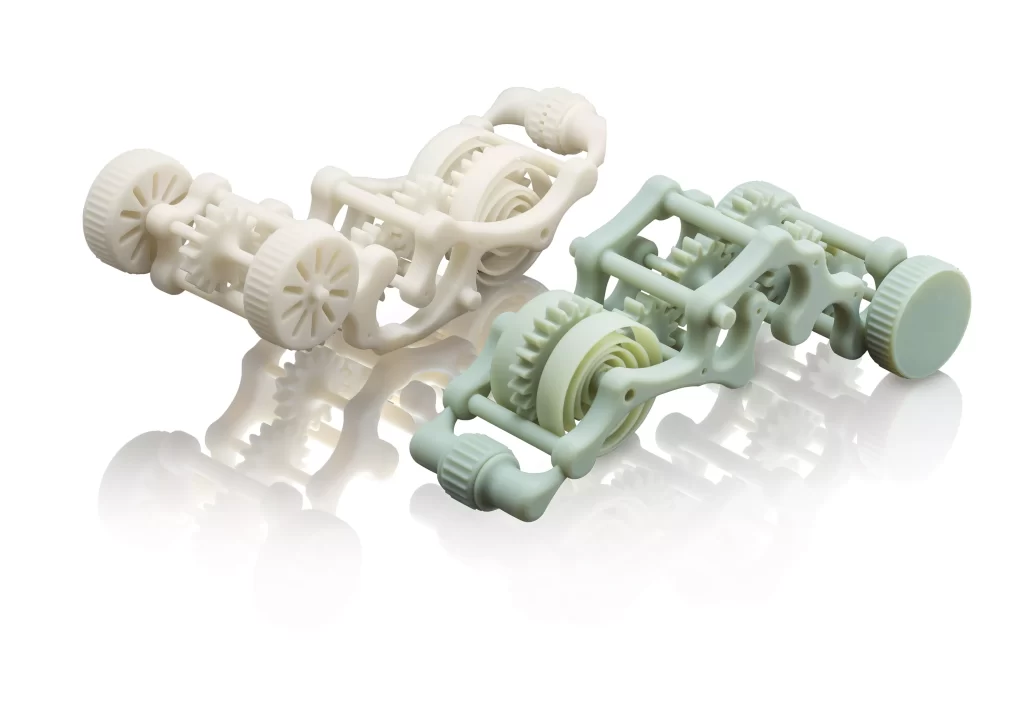

Multi-material 3D printing for full-color, transparency, and flexibility in a single model.

Polyjet 3D Printing Services in Rapid Manufacture

Rapid Manufacture delivers quality parts at competitive prices; quickly. Rapid Manufacture has large Objet machines ideal for prototype and production multi-jet projects. Rapid Manufacture offers the most commonly used processing materials such as black ABS-like materials, transparent materials and elastomers on demand.

And with delivery times for our Polyjet taking just 1 working day, it’s no surprise that Rapid Manufacture is one of the fastest factories offering this range of services. We have several large format Objet Polyjet printers available that are often just waiting for your hot projects to arrive. We can provide consultation on rapid prototypes, appearance models, etc. Just contact one of our team members to find out why Rapid Manufacture is the best choice for all your Polyjet needs.

Ready to Get Started?

From design to prototype and production, our team of engineers is ready to help bring your idea to life with 3D printing.Get 3D-printed elastomeric parts within days. Request an online quote today.

Get Colorful Demonstration Models and High-Fidelity Prototype Parts

Vibrant color options and one of the fastest of our technologies, the PolyJET process is an ideal choice for attractive, high precision models needed quickly. PolyJET 3D printing rapidly produces parts with astonishingly fine detail, smooth surfaces, and precision. The technology works with a vast array of materials, including rigid opaque in hundreds of vibrant colors, clear and tinted translucent shades, rubber-like flexible materials, and specialized photopolymers for 3D printing in the dental, medical and consumer product industries.

Similar to an inkjet printer, this process jets layers of liquid photopolymer that is instantly cured with UV lights attached to the print heads. This speedy process creates fine layers for high resolution parts (up to 16 microns) that are produced quickly, sometimes in the same day. PolyJET is also popular for its ability to print multiple materials, durometers, and colors in one print – as well as living hinges, overhangs, and complicated geometries without needing to be assembled.

Polyjet General Tolerances

| Description | Tolerance Notes |

|---|---|

|

General Tolerances |

+/- 0.004” for the first inch is typical, plus +/- 0.002” for every inch thereafter. |

|

Build Area |

Build area up to 19.3″ x 15.4″ x 7.9″. |

|

Minimum Feature Size |

0.050″ or greater for rigid. 0.060″ or greater for rubber-like. |

|

Standard Layer Height |

0.0010″ layers. |

Full Color 3D Printing through PolyJet

Rapid Manufacture offers a full-color, high quality 3D printing service in addition to black, white, translucent, and grayscale utilizing the latest generation of PolyJet equipment from Stratasys. With over 600,000 available colors, Rapid Manufacture can print color 3MF and other 3D formats. Have a Pantone, RAL, HEX, CMYK, or other color input? Choose “Custom” and write in the combination in your notes for a Rapid Manufacture quote!

- VeroUltra™ Black (RGD865)

- VeroUltra™ White (RGD825)

- VeroCyan-V (RGD845)

- VeroMagenta-V (RGD852)

- VeroYellow-V (RGD838)

- VeroUltraClear Component (RGD820), VeroClear (RGD810)

- Agilus30 and rubber-like digital materials

- Digital ABS Plus, Ivory (upon request)

- Rigur, White (upon request)

PolyJet Materials

| Material Name | Description | Shore Hardness | Elongation at Break (%) | Notched Impact Strength (J/m) | Data Sheets |

|---|---|---|---|---|---|

|

Photopolymer, Rigid |

VeroUltra™ Black (RGD865), VeroUltra™ White (RGD825), VeroUltraClear Component (RGD820), VeroClear (RGD810) |

83D – 86D |

7% – 12% |

19 – 25 J/M |

VeroUltra, Vero |

|

Photopolymer, Rubber-like (Digital rubber) |

Agilus30 + Vero |

26-28A, 35-40A, 45-50A, 57-63A, 68-72A, 80-85A, 92-95A |

185% – 230% |

N/A |

Agilus30 Material Data Sheet, Digital Materials Data Sheet |

|

Multi-Material, Mult-Color, Digital material |

Combination of two or more PolyJet materials |

Varies |

Varies |

Varies |

Digital Materials Data Sheet |

What is PolyJet 3D Printing?

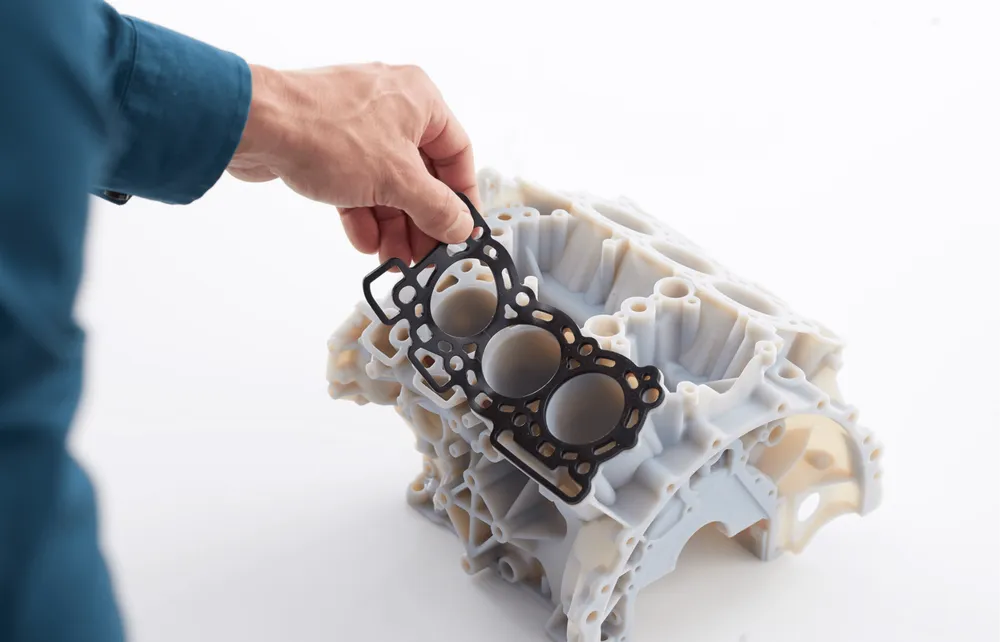

PolyJet is the only 3D printing technology able to create highly detailed parts with a smooth finish making it a valuable prototyping tool for a wide range of industries, from product design and engineering, to healthcare and education. PolyJet’s unique ability to 3D print using multiple materials allows for the production of parts with a wide range of physical properties including soft rubber, rigid, clear and opaque surfaces all in a single print. This versatility combined with the excellent surface finish makes PolyJet ideal for quickly creating highly aesthetic prototypes that mimic injection molded plastics. PolyJet Matrix empowers designers with the ability to create rubber-like prototypes with variable shore hardness, making it ideal for applications such as over molds, soft touch parts, and assemblies. By harnessing PolyJet Matrix 3D Printing, designers can achieve intricate and customized designs with exceptional precision and efficiency, expanding the horizons of what is achievable in 3D Printing.

How does PolyJet™ material jetting 3D printing work?

PolyJet 3D Printing is an advanced technology that quickly creates precise parts using photopolymers, UV light, and inkjet heads. It achieves accuracy by layering resins to form digital materials. The process starts with a CAD model transformed into a printable format. Drops of photopolymer are jetted onto the build platform, then cured with UV lamps to bond layers. Support materials are dissolved or manually removed for the finished PolyJet model.

Common PolyJet 3D Printing Applications

PolyJet 3D printing has a diverse range of applications across many industries.

- Form and fit testing and product presentation

- Prototyping for complex parts

- Product development

- Prototyping designs for overmolding or silicone rubber parts

- Combining two colors or durometers into a single part

- Simulating elastomers or flexible parts

- Anatomical models

What are the advantages of Polyjet technology?

PolyJet technology is known for its great surface finish, which allows to create detailed and smooth prototypes. This manufacturing technology is popular for rapid prototyping because of its excellent precision to CAD files. This resin technology can create detailed features, complex shapes, and delicate characteristics. Its an efficient technique, which incorporates a wide range of materials and colors into individual models.

Some resin materials available with the Polyjet technology offer a rare characteristic. Indeed, the VeroClear material, that we will see more into details after, has the adaptability to become transparent after polishing.

Start Printing Today

Whether you’re looking for an initial prototype or ready for low-volume production, send us your CAD files and we can get started. Upload design files to the instant quote system to get a free quote for your project. If you have questions about any part of Rapid ManufacturePolyJet 3D printing services, please feel free to contact us.