Laser Tube Cutting Services

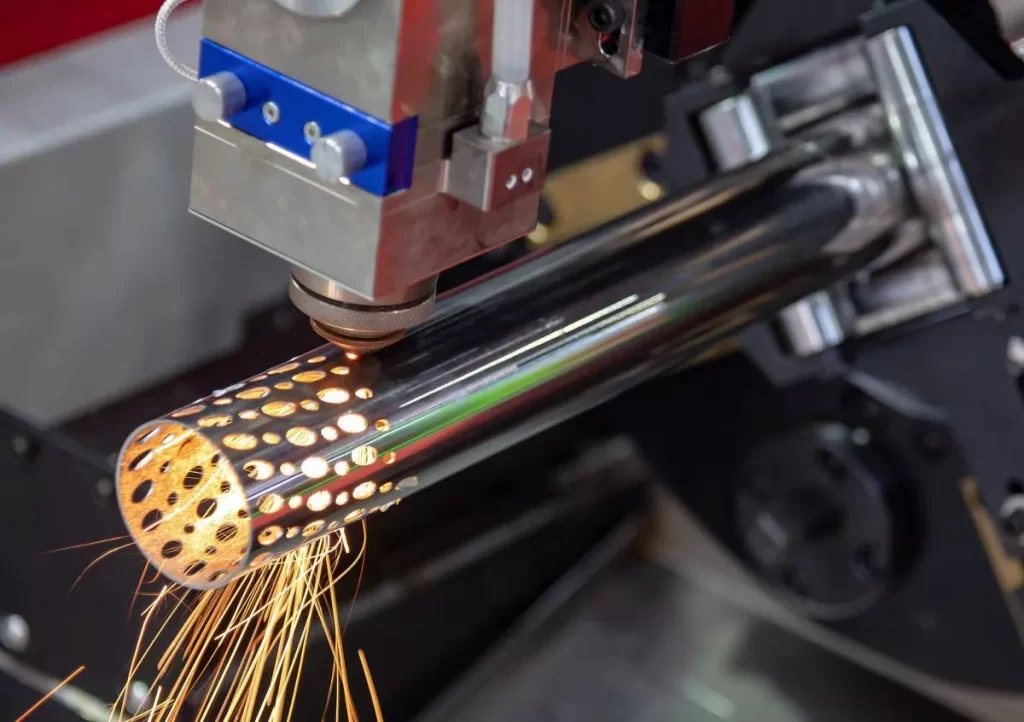

Rapid Manufacture provides tube laser cutting for metal and non-metal tube and pipe of various geometries.

Precise, high-quality tube laser cutting service with rapid lead times and competitive prices

Rapid Manufacture is one of the leading pipe laser cutting service providers in China, with an impressive, state-of-the-art laser cutting machine suite that operates 24 hours a day. Complemented by an in-house design team and end-to-end processing services, Rapid Manufacture’s tube laser cutting services are unparalleled.

Whether your cutting requirements are large or small, simple or complex, Rapid Manufacture ensures your project is worry-free. Laser cutting of tubes, also known as 3D cutting, has been proven to reduce material costs, increase downstream productivity and deliver competitive advantage. Unlock new design possibilities and optimize parts for efficient manufacturing with our multi-axis tube lasers.

Rapid Manufacture continues to expand processing capabilities to ensure efficient and cost-effective results for our customers. We are pleased to announce that our factory is now equipped with an advanced fiber optic tube laser cutting machine that eliminates the need for secondary processing. Using state-of-the-art technology, these machines can cut, groove, chamfer, etch, add holes and complete complex designs in one continuous step. Our team of experienced estimators and account managers can assist from start to finish, ensuring timely, high-quality results every time; plus, we can ship your completed components directly to your dock or door.

Laser Tube Cutting Services Online Quote

Using Rapid Manufacture’s online quote engine, it is simple to start a quote for your next laser tube cutting project.

Our project managers and experts personally review and manually quote each laser tube cutting project to ensure we meet your unique needs while providing a fast and easy manufacturing experience.

Efficiency

CNC fibre laser cutting machines operate 24-hours a day for rapid lead times at competitive prices.

Quality

ISO9001 and BS/EN 1090-1 accredited service delivers reliable quality on the largest and most complex projects.

Experience

Over 20 years’ laser profiling experience using the latest cutting technologies. Our investments, your benefit.

What is Laser Tube Cutting?

Laser tube cutting is the process by which tube stock material is selectively cut to form various shapes, holes, designs, and/or channels using a controllable precision laser. The stock material (tube/pipe) is held in a controllable lathe, where the tube will rotate in line with the design specifications as the laser makes cuts. Laser tube cutting can create through-holes of any shape as small as the wall thickness of the material, and is also often used to cut channels that allow for easy bending and welding of the tube for angled tubing.

Laser Tube Cutting Material Options

| Material | Round Tube | Pipe | Rectangular Tube | Square Tube |

|---|---|---|---|---|

|

Aluminum |

|

|

|

|

|

Steel |

|

|

|

|

|

Stainless Steel |

|

|

|

|

|

Brass |

|

|

|

|

|

Copper |

|

|||

|

Titanium |

|

|||

|

Plastics |

|

Summary of Tube Laser Cutting Nominal Tolerances

| Parameter | Tolerance |

|---|---|

Facet-to-feature | ±0.005” |

Feature-to-feature | ±0.003” |

Hole/Slot diameter | ±0.003” |

Minimum feature size | No smaller than wall thickness |

Tolerances

Rapid Manufacture’s tube laser services can maintain tight tolerances: Tube laser cutting can achieve a tolerance of ±0.005” from the quadrants of the tube (called facets) to the feature. This ±0.005” value also applies to feature-to-feature cutting. Hole or slot diameter tolerances can be more tightly controlled to ±0.003”. The minimum feature size depends on the material and material thickness, but generally, the minimum feature size is no larger than the wall thickness (i.e., the diameter of the through hole can be no smaller than the wall thickness).

Stay Ahead of the Competition with our Tube Laser Cutting Services

Wall Thickness

Generally speaking, all laser tube cutting services with Rapid Manufacture can achieve standard cuts up to 3/16”; however, deeper cuts up to ⅝” can be achieved using a WAC (water-assisted cutting) system alongside the laser tube cutter. Kerf sizes vary based on the specific material, laser type, laser power, and operation parameters, but are overall much thinner than traditional cutting methods, reducing material waste.

For laser tube cutters that offer cut head angles (i.e., 5-axis laser tube cutters), note that angled cuts will change the effective wall thickness of the tube, so it is important to choose a tubing thickness that will not exceed maximum wall thickness when angled.

Structural Shapes / Profiles

It is essential to note the difference between pipe and tubing when discussing structural shapes; pipe is measured in schedule (i.e., ½’ schedule 80 pipe, useful in standardized applications) while tube is measured by its wall thickness (i.e., outer diameter + inner diameter). In either case, laser tube cutting systems typically have settings for both measurement standards and offer custom setups for unique or non-standard structural shapes.

Rapid Manufacture can provide laser pipe cutting on tube and pipe profiles including:

- Rectangular tube

- Round tube

- Square tube

- Square tube with a radius corner

6 Reasons to Choose Rapid Manufacture Tubes for Tube Laser Cutting

- Precision: Laser tube cutting not only eliminates human error; it relieves you of having to pay top dollar for a highly experienced worker.

- Speed: Before tools like the Mazak 3D Fabri Gear 400 II and the BLM LT8, tubes had to be processed by hand. To achieve precision, workers had to cut very slowly. As a result, processing a tube could take hours.

- Rapid Manufacture is excited to offer in-house laser processing of mechanical and structural tubing and pipe.

- The Mazak 3D Fabri Gear 400 II and the BLM LT8 has reduced this time to mere minutes.

- Efficiency: Laser tube cutting services deliver ready-to-assemble, turnkey parts. We can laser cut parts with a tab and a slot so that you can snap them together and weld them, without having to build a jig and a fixture to hold them in place.

- Eliminate Deburring: The precision you get with laser tube cutting isn’t just about making cuts that meet print. Our laser tube cutting tool makes clean cuts, eliminating the need for deburring.

- Free Up Capital: We invested in the Mazak 3D Fabri Gear 400 II so you don’t have to.

- Rapid Manufacture’ laser tube cutting services frees up capital; instead of allocating capital toward bringing this technology in-house, you can put toward other important upgrades or expenses.

- Depth of Inventory: At other shops, you may have to wait if you need a size that they don’t keep in stock. Rapid Manufacture stocks round, square and rectangular steel tubing in a wide variety of sizes and lengths. We save you from having to wait or sourcing the material yourself. View our steel tube stock list here.

Need assistance with your project? Request a free quote and turn your concept into reality today

Laser cutting of tubes eliminates the need for secondary processing, shortening lead times and lowering manufacturing costs. You can expect precise results for the most complex parts. We accept DWG (3D), DXF, IGS, IPT, STEP and PDF print files, plus our online quoting system provides accurate quotes, efficient material utilization and significant cost savings.