Custom Online Laser Cutting Service

Get high-quality laser cutting services for prototypes and production parts. Custom high-precision laser cut parts with excellent dimensional stability. At low prices, fast lead times.

Cutting Service With Rapid Manufacture

As a full-service metal fabrication company, Rapid Manufacture offers a variety of services to meet your needs. One of our most popular services is metal laser cutting.

This is an adaptable and precise way to cut metal, and we are able to cut a wide variety of materials, including stainless steel, aluminum, and even titanium. In addition to being fast and efficient, laser cutting produces clean, consistent cuts that require little or no post-processing.

This makes it an ideal choice for projects that require tight tolerances or intricate designs. So, whether you need a few custom parts or a large production run, our team at Rapid Manufacture can help.

Why settle for ordinary when you can have extraordinary? Make the switch to our metal laser cutting services today and see the difference! If you’re looking for outstanding quality and service, look no further than Rapid Manufacture.

Fast and efficient production of laser cut parts with speedy delivery!

Rapid Manufacture offers instant quotes for your custom laser cut parts. Our customer service team will work with you to ensure your design specs are met. Order your part easily by following these steps:

Create or Upload your CAD file – Design your parts using our free CAD or upload your CAD files, PDF drawings, or images.

Configure your part – Select from over 50+ materials and surface finishes. Enter quantity, address and any special comments to the machinist.

Receive a quote – Get a quote for your design (instantly via our CAD).

Order your parts – Place your order and receive your quality CNC parts!

Laser Cutting From Prototyping to Production

The versatility and precision of laser cutting ensure excellent initial product development and continuous production. Design files are rapidly turned into end products, from intricate custom parts to complex enclosures.

Preparation of Blanks

Rapid Manufacture uses high-precision laser cutters to create material blanks and prepare flat patterns for prototyping and production.

Rapid Prototyping

Compatibility with various materials, production speed, and low cost per unit make Rapid Manufacture’s laser cutting services ideal for creating prototypes of end products.

On-Demand Production

Sheet metal laser cutting service offers high throughput with incredible precision for many applications, making it an excellent technology for end-use parts.

Laser Cutting Design Guidelines

Follow these guidelines for flat, laser cut parts to ensure quality and accelerate production time.

| Maximum Size |

|

| Minimum Part Size | 0.25 in. x 0.25 in. |

| Material Thicknesses | 0.024 in. – 0.250 in. |

| Tolerances |

|

Laser Cutting Materials

To help engineers choose the right material, we have over 450+ materials in stock, all of which are suitable for laser cutting and provide for precision capabilities. Our engineered materials means that the internal structure, consistency, and density is uniform, which creates parts whose exact weight, tensile strength, and center of mass is well defined. At the same time, engineered materials guarantee precision among different parts, even if they are manufactured at different times.

Of course, there will be applications that call upon very specific materials, and we accept custom material requests. If you require a custom material, let us know what the material is and where it can be purchased from so we can provide an accurate quote, but remember, we can only cut laser-safe materials.

| Material | Grade | Thicknesses Available |

| Aluminum |

|

0.025 in. – 0.250 in. (0.635mm – 6.35mm) |

| Steel |

|

0.025 in. – 0.250 in. (0.635mm – 6.35mm) |

| Stainless Steel |

|

0.025 in. – 0.250 in. (0.635mm – 6.35mm) |

| Copper |

|

0.025 in – 0.125 in. (0.635mm – 3.175) |

| Brass |

|

0.025 in. – 0.125 in. (0.635mm – 3.175) |

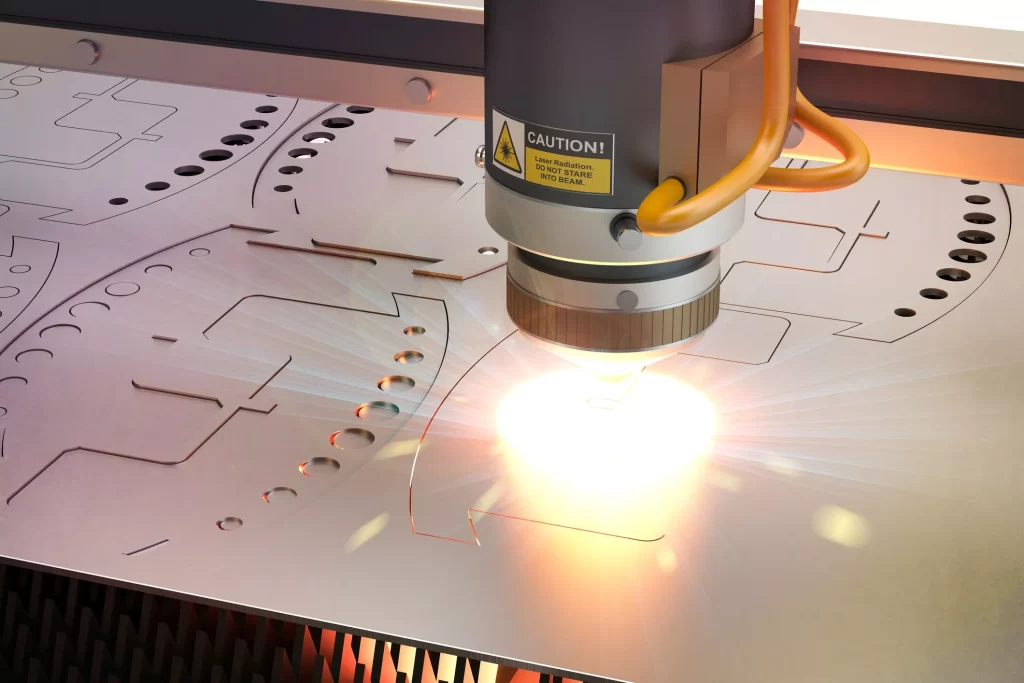

What is laser cutting?

Laser cutting is a process where a high power laser light beam is used to cut through materials. The material either melts, burns or vaporizes by the laser beam, leaving a clean edge. Laser cutting is a precise process and can be used to cut simple and complex shapes, for metal cutting or laser engraving.

Laser metal cutting is the new standard for cutting 2D parts from large sheets of raw materials. Online laser cutting services offer a convenient way to have materials cut by a laser. Laser-cutting steel is one of the most popular applications of this technology. A laser cutting company can cut many materials for sheet metal fabrication of small and large production runs.

Advantages of Laser Cutting

Our laser-cutting services are accurate, cost-effective, and create clean cuts that require minimal secondary processing. Other advantages include:

- Fast set-up and processing. Laser cutting does not require tool changes between cuts and the platform is the same for cutting different shapes.

- Precision. Features as small as 0.0002 inches (5 microns) can be cut reliably, with no thermal damage.

- Speed. Laser-cutting services are faster than traditional mechanical cutting methods, especially for complex geometries, with no tool changeover required.

- Quality. Laser-cut products show consistent quality, with micron tolerances and high aspect ratios, thanks to high constant speed and automated platforms.

Why Use CNC Cutting?

Laser cutting allows great flexibility, accuracy and top quality. It can cut very complex shapes.

State of the art automated laser cutters need little manpower. Combining their autonomous nature to their swiftness, Rapid Manufacture’s online laser cutting platform enables keeping your project costs low.

The accuracy tolerance for positioning is +/- 0.1 mm. Thermal effects on the material are small, therefore it is possible to cut small holes with a minimum diameter of 1/2 the material thickness as well as holes that can be threaded after cutting without requiring additional machining. The cutting line width it is smaller than 0.5 mm for most materials.

Rapid Manufacture’s manufacturing factory offers lasers that can cut a number of materials. These include carbon steel, stainless steel, high-strength steels as well as non-ferrous materials like aluminium, brass, copper and titanium. For metal plates thicker than 20 mm, see more about our plasma cutting capabilities. Aluminium cutting has its own rules.

Gallery of Sheet Metal Laser Cutting Parts

Rapid Manufacture’s laser cutting service has covered a wide range of applications for many industries. Below are some of our previous laser cutting projects.

Laser Cutting for Various Applications

Many industries worldwide are gradually transitioning to laser cutting technology because it provides additional benefits such as precision, tight tolerance, flexibility, clean finish, enhanced productivity, and design complexity. Whether for prototype or full-scale manufacturing, switching to laser cutting saves time and money.

Ready to get started on your laser cutting quote?

Our team is always ready to discuss your needs. When you’re ready for a company that delivers ontime, every time, then it’s time to discuss how we can help you.