Injection molding services

- Free Injection Molding Analysis

- Solid Engineering Support

- Swift Turn-around Time

Professional Plastic Mold Manufacturer Rapid Manufacture

Rapid Manufacture, a full-service injection mold manufacturing company with in-house precision manufacturing facilities, can offer various services: plastic part design, mold and tooling design, manufacturing, material selection, and mass production. We pride ourselves on our ability to provide design-build capabilities to all of our customers. We can manage every aspect of the molding process, helping our customers save time and money.

Online Injection Molding Quote

Rapid Manufacture’s custom plastic molding services provide on-demand prototyping and production molding. Our customer-first approach means our injection molding manufacturing facilities will mold parts the way you need them, at any price, without having to compromise on design. We provide expert consultation with every injection mold quote and a project manager with every order to move your part from design to production. Our team has extensive experience in various industries, especially medical injection molding and liquid silicone rubber molding.

Explore Our Injection Molding Services.

At Rapid Manufacture, we understand the difficulty and pressure of product development. Working with a reliable injection molding manufacturer efficiently and professionally is important. Plastic injection molding is reliable and cost-effective, often used for high-volume product production and prototyping. Our injection molding services also include the following sub-functions:

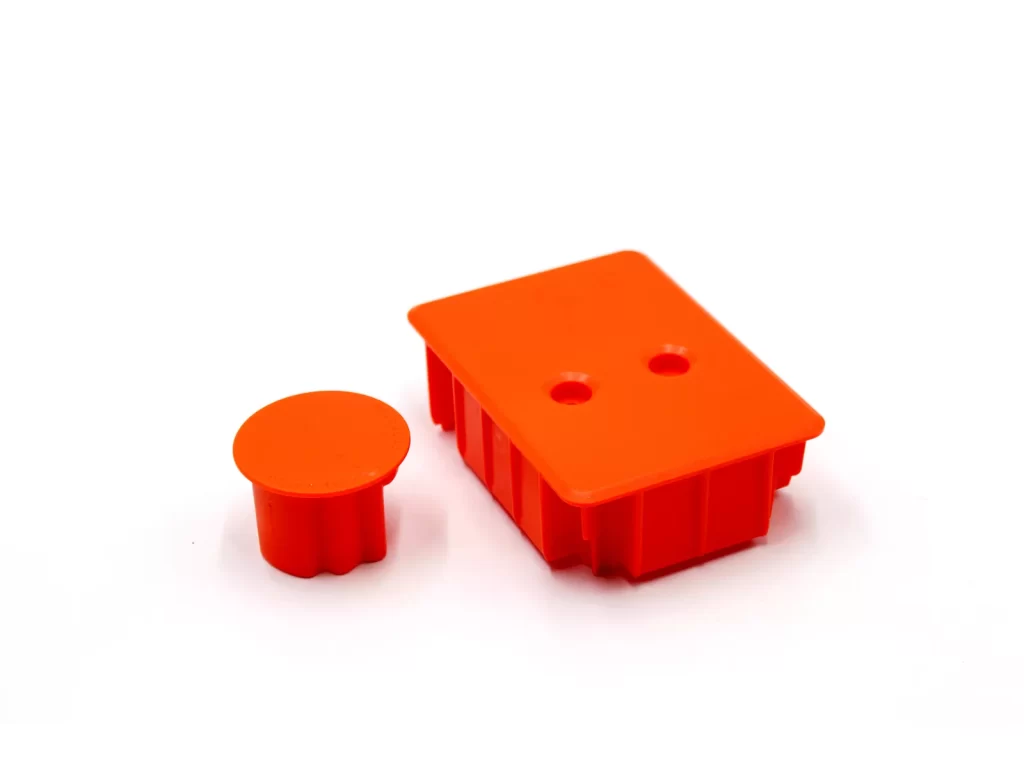

Insert Molding

Insert molding involves the injection of molten thermoplastic around a pre-placed insert to create strong, durable prototype parts.

Overmolding

Overmolding is a process in which multiple shots of thermoplastic are injected over or around a substrate to create highly customizable prototype parts.

Custom Plastic Injection Molding

Rapid Manufacture focuses on production volumes of 1,000 to 100,000 parts or assemblies per year. For each production injection molding project, we work closely with our customers on production feasibility and advanced quality planning (AQP) to achieve reliable, high quality production.

RapidTooling

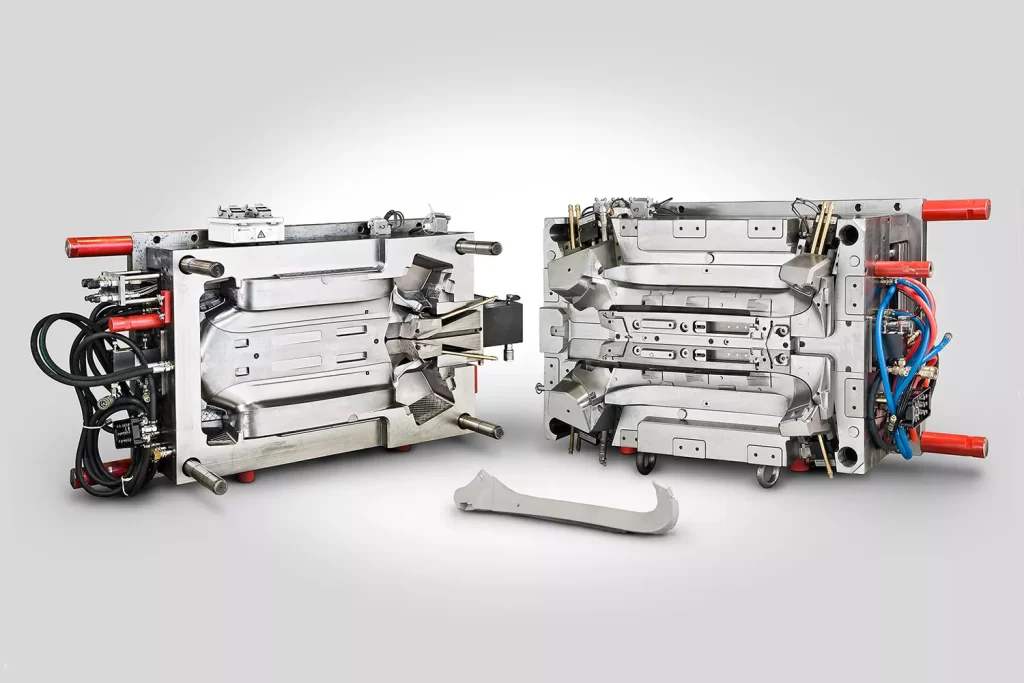

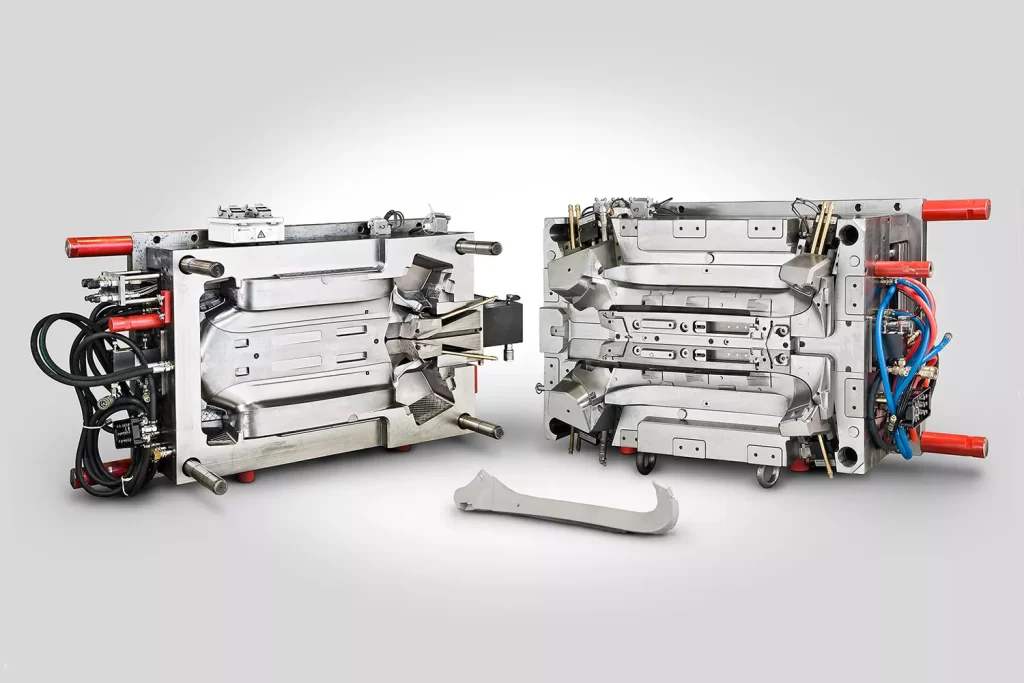

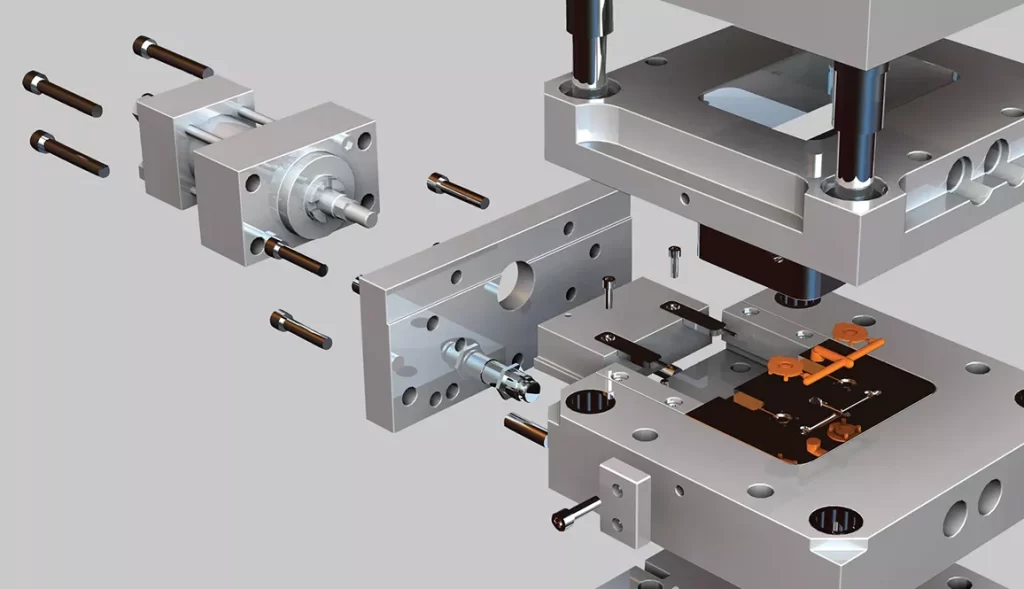

Injection molds are crucial for mass-producing precise plastic molded parts. Made primarily from steel or aluminum, their creation involves intricate design, precise machining, and assembly.

Why Choose The Services Of Our Injection Molding Company?

Prototyping within 7 days

Rapid Manufacture Injection Molding takes on 90% of the in-house manufacturing tasks so that we can offer you all molds within 0.005 mm accuracy.

22 years of experience complete solution provider

With 22 years of experience, Rapid Manufacture offers complete solutions, including product design, mold design, manufacturing, and injection molding.

Intellectual Property Protection

A project manager leads each project, overseeing specific details, logistics, and progress.

Our Capabilities

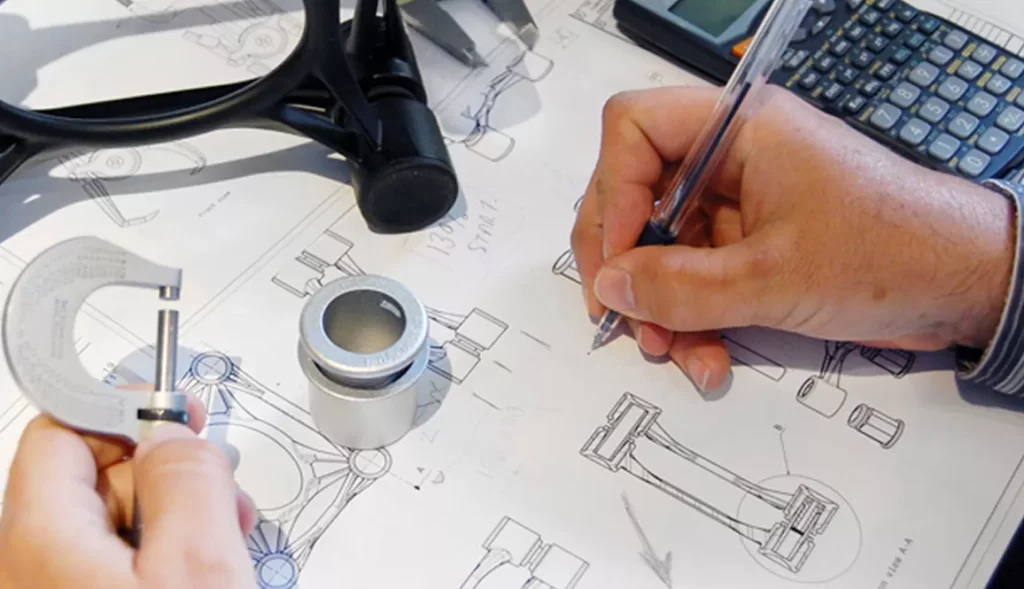

Product Design

For each project, whether you send us a sample or a 2D file, we will work with you to improve all technical drawings, including 2D files and 3D files of the product.

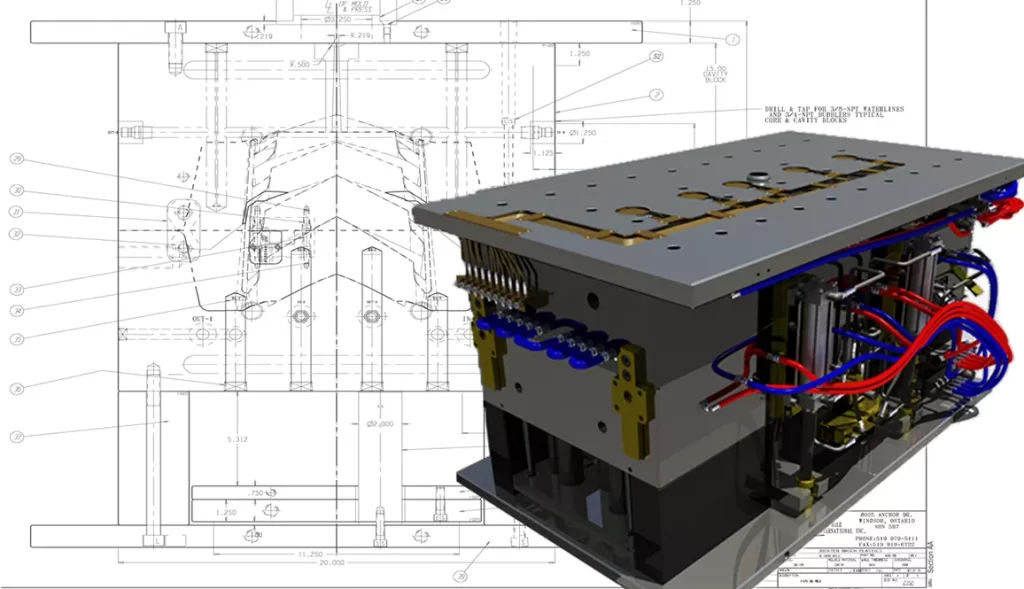

Mold Design

Mold design is the most important part of the whole mold making process because it determines the life of the mold. All molds are subject to mold flow analysis to prevent errors.

Mold Making

Our mold making process starts from analyzing steel. This is an essential procedure to make sure the density of steel, so that all FOW injection molds meet the standard. All parts are machined by high precision specialty machines like CNC Machine, Drilling Machine, Wire Cutting Machine, EDM, Lathing Machine, Engraving Machine.

Injetion Molding

From prototype, to pilot, to production parts, Rapid Manufacture injection company combines the latest Injection molding processes with proprietary technology and an experienced Injection Molding manufacturing team to deliver high quality, on-demand injection molded parts.

Injection Molding Materials

Rapid Manufacture commonly uses the following materials. If the material you use is not mentioned, please get in touch with us.

| Common thermoplastic materials | Other supported materials | Additives and fiber |

|---|---|---|

| Acrylonitrile Butadiene Styrene (ABS) | Nylon (PA 6, PA66, PA12) | UV absorbers |

| Polyethylene (PE) | Polycarbonate/Acrylonitrile Butadiene Styrene (PC/ABS) | Flame retardants |

| Polypropylene (PP) | Polyurethane (PU) | Plasticizers |

| Polycarbonate (PC) | Polymethyl Methacrylate (PMMA/Acrylic) | Colorants |

| High Density Polyethylene (HDPE) | Glass fibers | |

| Low Density Polyethylene (LDPE) | ||

| Polystyrene (PS) | ||

| PEEK | ||

| POM (Acetal/Delrin) | ||

| Polyethylene Terephthalate (PET) | ||

| Thermoplastic Elastomer (TPE) | ||

| Thermoplastic Vulcanizate (TPV) | ||

| Polyetherimide (PEI) | ||

| Polysulfone (PSU) | ||

| Inquire for additional options |

Our custom Plastic Injection Molding capacity

Optimize your injection molding project with these key production considerations

General process information

| Maximum part size | 800 x 800 x 400 mm 31.5 x 31.5 x 15.7 in |

| Minimum part size | 1 x 1 x 1 mm 0.04 x 0.04 x 0.04 in |

| Tolerance | Best achievable tolerance: ±0.001″ (0.025mm) Standard: ±0.005″ (0.127mm) For larger part tolerances please contact a Rapid Manufacture engineer |

| Lead time | As low as 2 weeks for T1 samples After T1 sample approval, lead time for < 10,000 parts is as low as 1 week |

| Tool validation | Standard process is to produce a small set of T1 samples for approval before initiating full production |

| Maximum press size | 1600T |

| Minimum order size | 100 parts and $5000 |

| Set-up fee | $500 per mold per order (applies to sample runs after initial T1 samples or engineering changes) |

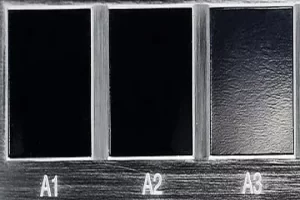

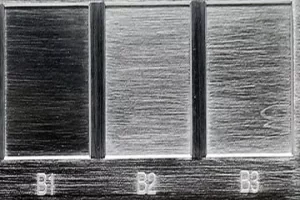

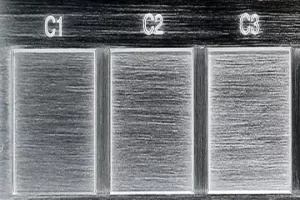

Surface Finishes of Injection Molding

Injection molding includes injection mold tooling, plastic injection molding, and more. The surface treatment of the mold is usually completed during the production process. After the injection molding is completed, we will carry out certain surface treatments on the finished product as per your requirement.

| Glossy | A grade finishes are made using a diamond buffing process and yield shiny and glossy surfaces on injection molded parts. | Learn More>> |

| Semi-glossy | B grade finishes use grit sandpaper to produce parts with a slightly rougher finish than grade A parts. Custom molded plastic parts that undergo B grade finishing have a matte surface texture. | Learn More>> |

| Matte | C grade finishes use grit sanding stones to produce a rough, uneven surface. Injection plastic parts that undergo C grade finishing have a matte surface texture. | Learn More>> |

| Textured | D grade finishes use grit and dry glass beads or oxide to produce a very rough textured finish. Depending on the type of material used, products can have a satin or dull finish. | Learn More>> |

Our Injection Molding for Various Industrial Applications

Injection molded parts have endless applications in industrial, commercial, residential, and consumer markets. From concept and design to prototyping and mass production, plastic molded parts are everywhere. Since its inception, Rapid Manufacture has worked in the agricultural sector, collaborating to manufacture parts for companies in the machinery and equipment, consumer market, material handling, marine, oil and gas, transportation, and sports markets.

Some Tooling & Unit Price For Your Reference

General Cases for IoT Logisitics

Project Description:4 plastic parts, 4 injection molds

General Product Size:170*99*40mm

Technical Specialty:4 Multi-Cavity Injection Mold

T1 Samples’ Lead Time:24 days

Tooling Life Time:300k

Tooling Price:USD 18000

Part Material:PC/ABS AC2300

Batch Quantity:225,000 sets/batch

Unit Price:USD 1.35/set

Lighting Cases for Aerospace

Project Description:12 plastic parts, 9 Injection Molds

General Product Size:590*35*30mm

Technical Specialty:3 Plates Mold

T1 Samples’ Lead Time:28 days

Tooling Life Time:300k

Tooling Price:USD 42,000

Part Material:PC/ABS FR 3010

Batch Quantity:10,000 sets/batch

Unit Price:USD 7.90/set

Charger Case for New Vehicle Car

Project Description:8 Plastic Parts, 2 Silicone parts,9 Molds

General Product Size:390*320*260mm

Technical Specialty:24 thread inserts for over-molding

T1 Samples’ Lead Time45 days

Tooling Life Time: 300k

Tooling Price:USD 48,000

Part Material:PC/ABS FR 3010

Batch Quantity:3500 sets/batch

Unit Price:USD 42.50/set

Get A Quote For Your Injection Molded Parts

Quoting is simple with Rapid Manufacture. Learn more about our quoting process here.