Die casting mold manufacturing

Looking for a quality die casting mold manufacturer? Rapid Manufacture is a custom designer, manufacturer and supplier of quality die-cast molds to meet your project needs. Contact us today to request a quote to complete your die casting mold.

Die Casting Service For Mold

If you have a project that requires custom die-cast molds, you’ve come to the right place! Rapid Manufacture is a top mold manufacturing services company in China, specializing in providing affordable, high-quality parts, plastic molds/formed parts, and die-cast molds and parts for lighting, medical, automotive, electrical, and many other industries. Molds and molded parts, including all finishing steps, surfaces and assembly.

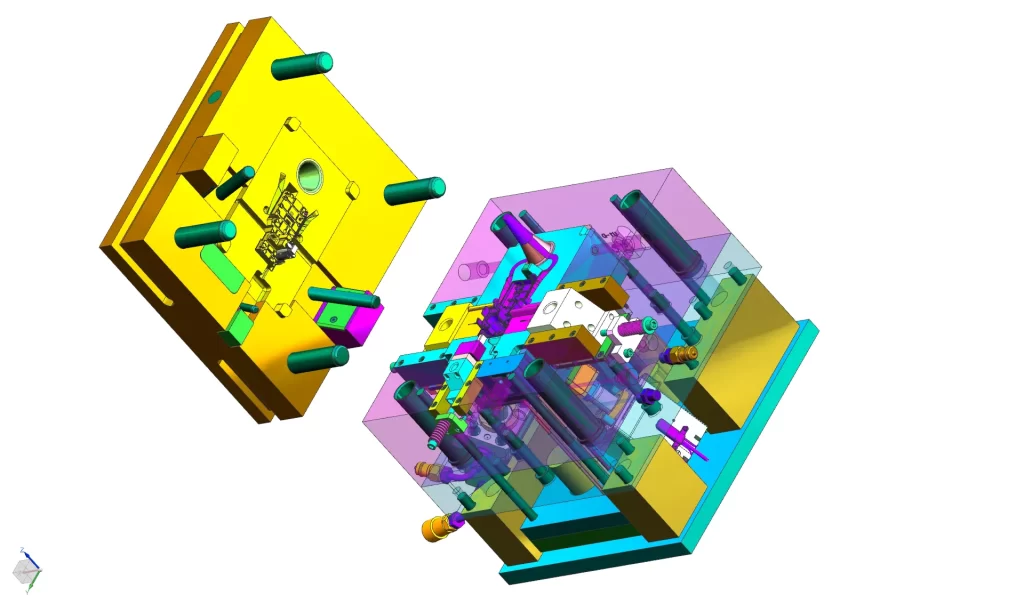

Our experienced engineers utilize the latest CAD/CAM and CNC machining to produce high-quality, durable molds optimized for your application. We provide complete mold design services including manufacturability analysis, simulation and prototyping to ensure flawless mold performance. With advanced equipment and expertise, Rapid Manufacture can provide complex, tight tolerance die casting molds based on your specifications. Our molds enable high-quality die castings to be produced quickly and efficiently in high volumes.

Die Casting Mold Online Quotation

Is the engineer’s quotation too slow? You can try the instant quotation system independently developed by Rapid Manufacture. Upload drawings and get quotes in seconds.

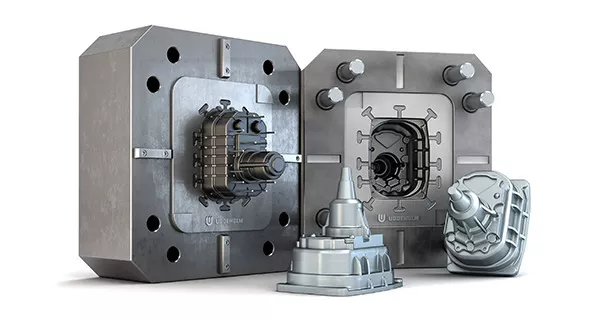

What Are Die Casting Molds?

Die-casting mould is a tool for casting metal parts. It is a tool for completing die-casting process on a special die-casting die forging machine. Basic process of die casting is that liquid metal is first filled into cavity of mould at low or high speed, and mould has a movable cavity surface. It is forged under pressure with cooling process of liquid metal, which not only eliminates shrinkage defects of blank, but also makes internal structure of blank reach broken grains as forged. Comprehensive mechanical properties of blank have been significantly improved.

Mold Materials For Die Casting

Rapid Manufacture offers die casting mold for aluminum, zinc alloys and steel, stainless steel: 4140, 4130, A36, 1018, 303, 304, 410, 17-4, 2205 Duplex, 440C, 420, 316, 904L, 2024, 5083, 6061, 6063, 7050, 7075, etc.

How are Die Casting Molds Manufactured?

Die casting is a manufacturing process commonly used to produce accurately dimensioned, sharply defined, smooth, or textured surface metal parts. It is accomplished by forcing molten metal under high pressure into reusable metal dies. The die casting mold manufacturing process follows the subsequent procedures regarding die cast mold manufacturing:

- A mold is created in at least two sections to allow the proper removal of the casting.

- The sections are mounted securely within the machine and are arranged so that one is stationary while the other is moveable.

- The two are tightly clamped together.

- Molten metal is injected into the die cavity, where it quickly solidifies.

- The die halves are drawn apart, and the casting is ejected.

Compared with sand or permanent mold processes, HPDC is the fastest method for producing exact non-ferrous metal parts.

Additional Considerations for Die Casting Mold Design

The quality of the design of a die casting mold largely determines the properties of the casting and the economic efficiency. When designing and producing a die casting mold, the following should be considered:

- Dimensioning of the die casting mold

- Selection of mold steels (s. Hot-forming steel) and their heat treatments

- Design of the thermal fluid die heating and cooling

- Design and calculation of the casting system and the (forced) ventilation

- Ease of maintenance

- Production which is adapted to service life

- Number of mold cavities

Advantages Of Our Mold Making Service

- We have rich die casting mold parts manufacturing experiences for over 10 years and earned a good reputation.

- Our engineers can combine multiple processes to reduce costing with their rich experience so the price of our die casting mold products is cost-effective.

- Finish the parts in time to provide the strongest support for your R&D projects.

- Exceptional customer service and communication.

- Do precision die casting molded parts manufacturing according to your drawings or samples.

- High production capability and competitive prices.

- On-time delivery.

Contact Rapid Manufacture today to get started on your custom die casting mold project

Die casting molds from Rapid Manufacture Die Casting and Machining utilize aluminum and zinc alloys to produce small to large run part identical castings for the customers. Die cast mold making is a versatile process that enables the production of different quantity castings.

Contact us to know more information regarding die cast mold manufacturing processes and we are willing to assist you with any questions regarding die cast molds and numerous die cast mold processes.