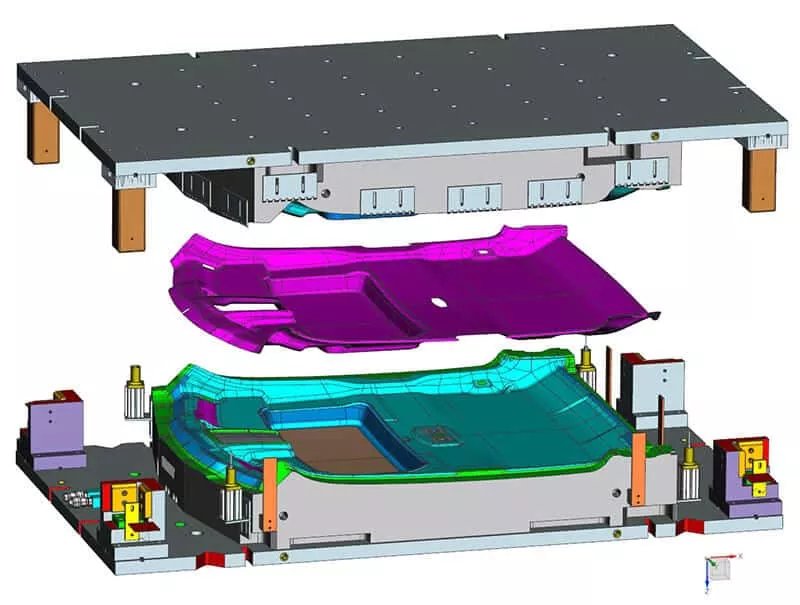

Compression Mold

Rapid Manufacture has deep experience in designing and producing plastic & compression molds for a variety of industries including automotive, RV, heavy-truck, aerospace and personal watercraft industries, with our Century Series molds specifically focused on Class-A exterior body panel applications.

Our Expertise in Compression Molds

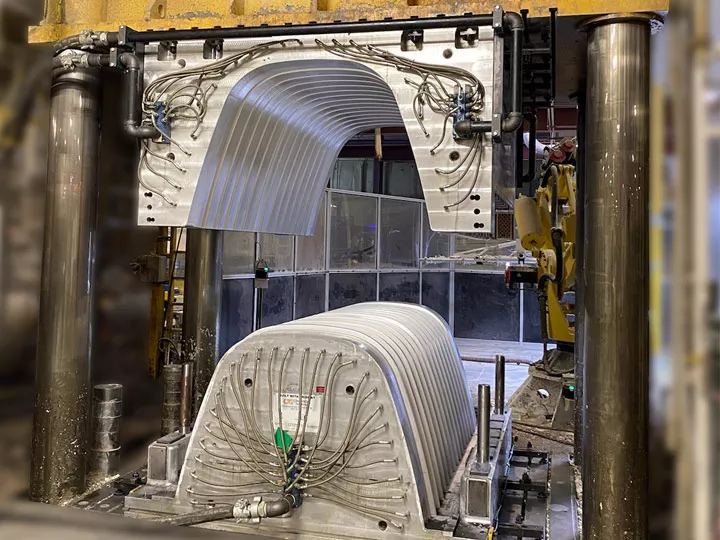

At Rapid Manufacture, we have always specialized in compression molds. We provide high-quality turnkey SMC or BMC compression molding solutions to customers across a wide range of industries. These molds are designed for medium to large parts with tight tolerances. We produce single or multi-cavity molds using a variety of hardened tool steels and optional coatings. Our engineering and design staff work with customers to find the most effective solution for each molding application.

All of our molds and tools are designed, engineered, and manufactured in-house based on customer-supplied part data. As a vertically integrated company providing everything from design through try-out, we’re able to maintain tight control over quality to provide custom services to meet your total program needs.

Our dedication to this technology has led to extensive process knowledge in the design and manufacturing of compression molds, enabling us to achieve complex geometries and exacting tolerances.

Compression Mold Quick online quote

Not sure how much it will cost to produce your design? Rapid Manufacture provides you with an online quotation platform. All you need to do is upload your design files to get a quote. Rapid Manufacture is the go-to company for your Compression Molds needs. Our premium injection molding services include rapid tooling services. We tailor our services to meet our clients’ needs, ensuring the production of high-quality prototypes.

How to Order Parts?

Not only can you get a free quote from our fast instant quote system, you can also get a free quote from a real engineer; once we receive your design, our engineers will review it and send it to you in as little as one hour Quotation.

Get A Quote Within 12 Hours

Upload your design or email our engineer directly and get your quotes as fast as one hour.

Start Production

Your mold will be made once your orders are confirmed. Besides, you will get real-time order updates of the production status from our order tracking system.

Receive Your Part

After all mold pass QC inspection, they will be well packed from transportation accidents. Then, your custom parts are delivered straight to your doorstep.

We offer compression molds for the following processes utilizing

- Sheet Molded Compounds (SMC)

- Bulk Molded Compounds (BMC)

- Direct Long Fiber Thermoplastics (D-LFT)

- Dicyclopentadiene (DCPD)

- Resin Transfer Molding (RTM)

- Carbon Fiber-Reinforced Plastics (CFRP)

What is Compression Mold?

Compression Mold is a process which is used to manufacture composite components in high volumes. In this type of Mold process, thermoset plastic material is used. It may be in free flow granular form or may be viscous material. With this process, various parts with wide array of lengths and thickness can be prepared. This type of Mold is used to produce gaskets and seals made up of synthetic rubber, silicone and natural rubber. The high quality stiff and durable rubber is used in a variety of industries including the automation industry. With compression Mold raw rubber material gets placed inside a pressurized mold. A plug is secured at the top of the mold. The purpose of the plug is to seal the mold and the plug is connected to a machine that allows for both heating and pressurization. The mold is then heated and pressurized. The rubber gets liquidated and expands. After expansion activity the material is allowed to cool down. Due to pressure the rubber material takes the shape of mold cavity. The rubber material gains a solid state, thereafter, the rubber casting can be ejected from the mold cavity. Rubber products of different shapes can be made by compression Mold.

What are the different types of compression mould?

There are different types of compression molds in the market, they may have different names due to different compression molding materials, such as SMC mold, BMC mold, GMT mold, LFT mold, but more often they are classified according to the compression mold structure.

compression mold advantages

- Molds for compression molding are generally simpler than their injection mold counterparts. There is no sprue and runner system in a compression mold.

- Better quality and consistency, high precision, uniform wall thickness and good surface finish can be achieved with good mold design.

- Reduced production time, increased productivity and efficiency, the reason behind this is that there is no waiting period between each cycle.

- Reduced tooling costs, MDC uses high-quality steel to improve the mold life.

What kind of mold steel is used for compression mold?

The steel used for compression molds is alloy steel, carbon steel. Alloy steel is a high alloy steel with very low carbon content and is therefore very tough. Carbon steel contains more carbon than alloy steel and is less hard, but is also cheaper than alloy steel. The most common steel used in compression molds is alloy steel. This is because the mold needs to be able to withstand the pressure of molten metal and low alloy steels can withstand higher temperatures than carbon steels.

we also use the best heat treatment process, and milling capability to meet the requirements of high precision compression mold. Rapid Manufacture controls the flash within an ideal range through CNC processing technology and the processing technology of mold steel to reduce the waste of materials as much as possible.

Compression Molds Industry Applications

- Carpet and flooring components

- headline News

- Trunk and cargo lining

- Flooring systems and components

- truck bed lining

- soundproof heat shield

- Door and floor insulation panels

- Interior and exterior instrument panels

- inserts and decorations

- Dashboard insulators and terminal blocks

- Die cut insulation

- armrest

- door decoration

- Body side molding

- bumper system

- Fascia

- ground effect

- Wheel covers

- painting

- Heavy truck body panels

Ready to Take on Your Next Project?

This is where you get it all. Request your free quote today, and enjoy the best Compression Mold Manufacturing services.