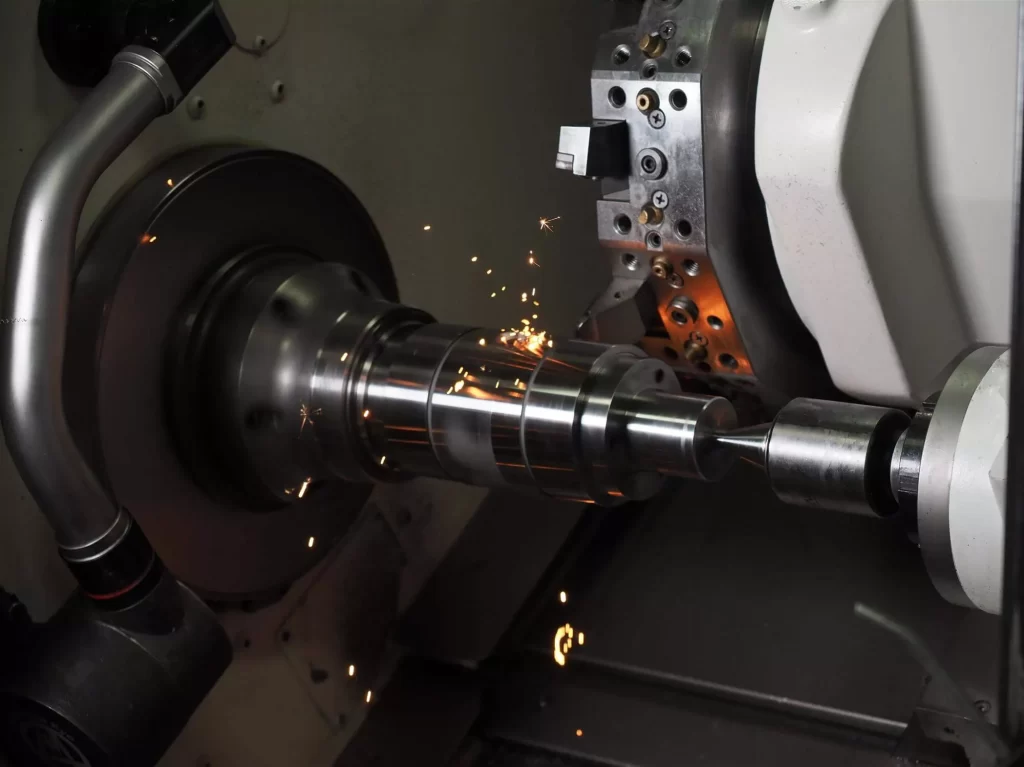

CNC Turning Services

Our CNC turning process produces custom prototypes and end-use production parts in as fast as 1 day. We use a CNC lathe with live tooling so features like axial and radial holes, flats, grooves, and slots can be machined.

Order high-quality CNC turned parts with Rapid Manufacture

Rapid Manufacture is dedicated to providing new product developers with state-of-the-art precision CNC turning services to complete any project. We use only the best machine lathes and imported cutting tools in our climate-controlled workshop. Of course, every step is carefully inspected to ensure it meets your specifications.

Our complete in-house manufacturing and finishing services complement your CNC turned components. Get reliable metal and plastic turned parts for your unique projects with our on-demand CNC turning services. With advanced technology and expert technicians, Rapid Manufacture produces high-quality custom prototypes and end-use production parts. Our CNC turning capabilities enable us to deliver high-precision turned components, regardless of complexity. You’ll get durable parts from flat surfaces to radial and axial holes, slots and recesses in a day.

CNC Turning Quote Online

Our on-demand manufacturing platform delivers high-quality metal and plastic CNC turned parts for rapid prototyping or low- to high-volume production. Rapid Manufacture provides the engineering and manufacturing capabilities you need for your project while also providing the most competitive pricing and delivery times. Our in-house designed and developed instant quoting platform also provides instant manufacturability feedback to ensure your parts are optimized for the CNC turning process and meet your required requirements. Simply upload your CAD files to the platform to get instant quotes and delivery times. After confirmation, we take care of the manufacturing aspect using state-of-the-art machinery.

Our Outstanding CNC Turning Machining Capability

With our strong capabilities in the CNC turning industry, we can provide advice on optimizing product design and feature combinations and then customize the CNC turning products you need based on your design drawings.

CNC Turning Metals Services

Rapid Manufacture has high-end turning capabilities for different metal materials. And with competitive machining speed and price advantage, the CNC-turned parts you need will be machined quickly and accurately.

CNC Turning Plastics Services

We can perform CNC turning of plastics. This includes ABS-turned parts, polycarbonate-turned parts, PMMA-turned parts, and Peek round parts with high-quality surfaces.

Turned Part Polishing Services

Rapid Manufacture serves as a one-stop solution factory. Many turned parts projects require polishing processes for better surface quality, and Rapid Manufacture can handle them quickly to meet our customers’ immediate needs.

Types Of CNC Turning Processes

Many types of CNC lathe services can be performed on CNC lathe field lathes, including hard turning, cutting off, facing, boring, reaming, taper turning, drilling, knurling, threading, grooving, etc.

- Taper turning: Machining cylindrical parts whose diameter gradually decreases from one end to the other.

- Hard turning: suitable for materials with Rockwell C hardness greater than 45, usually after heat treatment.

- Spherical generation: Create a spherical surface.

- Facing: The turning operation of processing the end face of the workpiece from the outer yard to its center, so that the end face is flat and smooth

- Parting: Creates deep grooves to remove a complete or partially complete component from its master batch.

- Grooving: Similar to parting, but only cutting to a specific depth from the outside or inside of the workpiece.

- Drilling: Use the drill fixed on the tailstock of the lathe to feed into the workpiece along the axial direction to remove the material and make a deep hole in the center of the shaft

- Knurling: Use a knurling tool with a pattern to cut a zigzag pattern on the surface of the workpiece

- Reaming: Removing a small amount of material from a drilled hole to obtain a high precision diameter.

- Thread: turning standard and non-standard threads, generally referring to single-point threads.

- Polygon Turning: Machining operations in non-circular forms that do not interrupt the rotation of the raw material.

Custom CNC Turning Services

Rapid Manufacture is a world-class CNC manufacturing supplier from China; our goal is to provide you with quality CNC turning services. We can manufacture various turned parts, such as automotive parts, medical turned parts, aluminium turned parts, metal bolts, valve spools, hydraulic fittings, camera lens housings, etc.

Our factory has advanced lathes, including advanced automatic lathes imported from Japan. We are confident that we can provide low-cost, high-quality precision lathe parts to customers in many industries worldwide. Please send us your RFQ information; you will get a quote reply soon.

Advantages of CNC Turning

Using the latest CNC machines, Rapid Manufacture produces highly accurate, quick turn parts in as fast as 1 day.

Select from a variety of finishes on solid metal and plastic parts, built to precise design specifications.

Choose from over 50 metal and plastic materials. CNC Machining offers a wide variety of certified materials.

Offers high-precision tolerances ranging from +/-0.001″ – 0.005″, depending on customer specs.

CNC Machining is perfect for production of 1-10,000 CNC machined parts.

Let's Start A New Project Today

About the CNC Turning Process

CNC turning is a particular form of precision machining in which a cutter removes material by making contact with the spinning workpiece. The movement of the machinery is controlled by computer instructions, allowing for extreme precision and repeatability.

Turning is different to CNC milling, in which the cutting tool rotates and is directed from multiple angles at the workpiece, which is usually stationary. Because CNC turning involves rotating the workpiece in a chuck, it is generally used to create round or tubular shapes, achieving far more accurate rounded surfaces than would be possible with CNC milling or other processes.

The tooling that is used with a CNC lathe machine is mounted to a turret. This component is programmed to make certain movements and remove material from raw materials until the desired 3D model is formed.

Like CNC milling, CNC turning can be used for the rapid manufacture of either prototypes or end-use parts.

CNC Turning Tolerances

As an ISO 9001 certified company, we machine CNC turning lathe parts to meet tight tolerance requirements. Based on your design, our CNC lattes can reach tolerances of up to ±0.005”. Our standard tolerances for CNC milled metals is ISO 2768-m and ISO 2768-c for plastics.

| Maximum part size | Ø 350 x 600 mm Ø 13.8 x 23.6 in Larger diameters may be feasible at shorter lengths. Contact us to discuss design options. |

| Minimum part size | 6.4 x 6.4 x 6.4 mm 0.25 x 0.25 x 0.25 in |

| Minimum feature size | • Ø 1 mm • Ø 0.039 in |

| Standard tolerance | Metals: +/-0.13 mm (0.005 in) Plastics: +/-0.20 mm (0.008 in) |

| Minimum wall thickness | Recommended size: 0.8 mm (0.031 in) for metals and 1.5 mm (0.059 in) for plastics Feasible size: 0.5 mm (0.019 in) for metals and 1.0 mm (0.039 in) for plastics |

| Holes | Recommended size: Diameter: standard drill bit sizes Depth: 4 x diameter Feasible size: |

| Threads | Recommended size: Size: M6 or larger Length: 3 x diameter Feasible size: |

| Lead time | As low as 8 days for less than 50 parts |

Materials for CNC Turning Parts

Our CNC turning processes are compatible with a wide range of materials, including machine-grade metals and plastics. Depending on your applications, we can create precise rapid prototypes and low-volume production from various superior-quality materials. Check out some of the common materials for your CNC turning projects.

- Stainless steel: SS201, SS301, SS303, SS304, SS316F, SS316, 420, etc.

- Steel: Carbon steel, alloy steel, mild steel, 4140, 4340, Q235, Q345B, 20#, 45#, etc.

- Aluminium: AL6061, AL6063, AL7075, AL5052, AL6082, etc.

- Brass: HPb63, HPb62, HPb61, Hpb59-1, H59, H62, H68, H80, H90, etc.

- Copper: C11000, C12000, C36000, etc.

- Plastic: PVC, POM, NYLON, etc.

- Alloy: Zinc alloy, Aluminium alloy, etc.

Surface Finishes for CNC Machining

With a wide selection of surface finishes, Rapid Manufacture can help improve the surface qualities of your products. Surface finishes applied to your CNC turned parts aim at improving their appearance, surface hardness and roughness, chemical and corrosion resistance, etc.

- As Milled – Cutter marks from the CNC turning process will be present. Surface finishing can get at Ra 0.8.

- Anodized – A thin and hard non-conductive coating is added to the surface of the aluminum parts. Parts can be anodized in different colors

- Heavy Bead Blast – this will remove heavier cutter marks and scratches left behind by sandpaper and will have a light texture appearance.

- Smooth Finish – This is typically 600 grit paper and can be polished.

- Powder Coat – Add a strong, wear-resistant, and corrosion-resistant protective polymer coating to the surface of the part. A variety of colors can be used to create the desired aesthetic effect.

Gallery of CNC Turning Parts

Check out our extensive gallery that shows precision turned prototypes and parts from our valued customers.

Our CNC Turning for Various Industrial Applications

Rapid Manufacture’s cost-effective and reliable CNC-turned parts see great use as crucial pieces in equipment for medical, consumer goods, and automotive fields, and more.

Get an Instant Quote For Your CNC Turning Project

With a range of finishing services to choose from and guaranteed quality thanks to our inspection services you can trust you will receive great parts every time. Once you send us your 3D CAD file for a free quote, one of our customer service engineers will check your design for manufacturability to ensure that the part can be made to your expectations and budget requirements