CNC Routing Service

Our Online CNC Routing Service ensure the sharp edges and tight tolerances you are looking for. Get a quote for custom parts with our online CNC Routing Service. Rapidly prototype and produce parts in days.

Our Online CNC Routing Services

Rapid Manufacture is a trusted industry supplier of innovative CNC Routing services. With its expertise, state-of-the-art technology and commitment to quality, Rapid Manufacture has become the go-to resource for businesses and individuals looking for best-in-class CNC Routing solutions for producing components and finished parts. Rapid Manufacture prides itself on providing the highest quality solutions to its customers.

We can work with businesses on recurring or one-off projects, and our services are also available on special projects. No project is too small or complex for us to handle. With fast turnaround times and great prices, we lead the market in providing CNC Routing services to global businesses looking to speed up their manufacturing processes.

Ordering your custom CNC Routing parts has never been easier

With our team of highly trained machinists and our state-of-the-art manufacturing technology, we’ve made it easier than ever to design and order CNC routed parts. Upload your design to our app, select your material, add any additional services, and get an instant quote!

What Is CNC Routing?

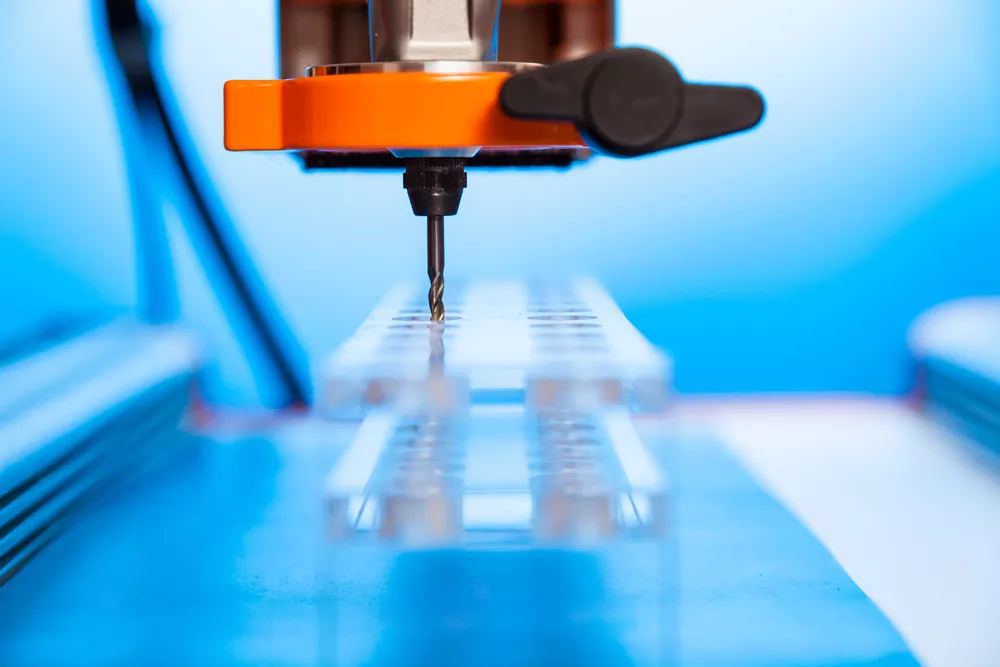

CNC routing is a cutting process in which material is removed from a sheet by a rotating tool. The computer numerical control (CNC) router moves mainly in two dimensions (the third dimension is plunging on the Z-axis) to achieve the desired part shape. The router rotates on an axis perpendicular to the table holding the cutting material. The cutting tool hovers over the sheet material from a rotating spindle. While the cutting tool turns, a computer controls the motion of the cutter. The cutter is guided to move through the material, removing portions to create shapes. CNC routers are efficient at producing precise cuts for complex designs.

- Cutting Tool: In CNC routing, a rotating router bit is used as the primary cutting tool, whereas CNC milling typically employs a rotating multi-point cutting tool called an end mill. CNC turning, on the other hand, uses a single-point cutting tool to shape cylindrical parts.

- Material Orientation: CNC routing machines are typically designed to work with flat or sheet materials, such as plywood or acrylic sheets, which are secured to a table. In contrast, CNC milling and turning processes often deal with block or cylindrical workpieces.

- Cutting Direction: CNC routing machines primarily operate in the X and Y axes, cutting along the plane of the material. CNC milling and turning machines, on the other hand, can move in multiple axes, allowing for more complex and three-dimensional machining.

- Applications: While there can be some overlap, CNC routing is often associated with applications that require large-scale cutting, such as furniture making, sign manufacturing, and cabinetry. CNC milling is commonly used for precise and intricate machining of parts, while CNC turning is ideal for producing cylindrical or rotational parts like shafts and fittings.

Advantages of CNC Routing

CNC routing offers several advantages over traditional manual routing or other manufacturing methods, for example,, plasma or laser cutting. Here are some key advantages of CNC routing:

- Tight Tolerances

- Flexibility

- Reproducibility

- Complex Shapes and Intricate Designs

CNC Routing Process at Rapid Manufacture

At Rapid Manufacture, the following steps are used to turn your designs into a finished product through CNC routing:

- Design the Part: First, start by designing your part using computer-aided design (CAD) software. You will save your work as a vector file. Vector files are commonly saved in the DXF format, but they can also be saved in other formats such as AI, BMP, CDR, DWG, PDF, STL, and SVG. These formats allow for compatibility with different CNC machines and software programs, ensuring seamless transfer and interpretation of the design data.

- Upload CAD File: The second step to getting your design made into physical parts is to upload your CAD file to our website in a compatible format using our instant quoting tool. Once the quote is accepted, we can take the next step.

- G-Code Conversion: After you accept the quote for the job, Rapid Manufacture will convert the CAD file to G-code. CAM (computer-aided manufacturing) software is utilized to convert vector files into G-code, which is a machine-readable language understood by CNC routing machines. By employing CAM software, the vector design is translated into a series of instructions that precisely guide the CNC router during the cutting process. This ensures that the machine accurately follows the intended tool path and executes the desired cutting, shaping, or engraving operations based on the original vector design. Other processes at Rapid Manufacture, including laser cutting and other CNC machines, use the same or similar process to our CNC routers.

- CNC Routing Execution: Rapid Manufacture will then initiate the routing process by running the CNC program. The machine will follow the pre-programmed toolpath, cutting or routing the material according to the design specifications.

- Finishing and Post-Processing: Once the routing process is complete, the finished part may require post-processing steps such as sanding, polishing, or surface treatment to achieve the desired final appearance and quality.

Common Materials for CNC Routing

CNC routers are compatible with a wide range of materials, including: soft metals, wood, plastics, and composites. Below is a list of some of the most common materials used in CNC routing:

- ABS (Acrylonitrile Butadiene Styrene)

- ACM Panel (Aluminum Composite Material)

- Baltic Birch Plywood

- HDPE (High-Density Polyethylene)

- MDF (Medium-Density Fiberboard)

- Polycarbonate

- Foam

- UHMW (Ultra-High Molecular Weight Polyethylene)

- Aluminum

- Brass

- Composites

Applications of CNC Routing

CNC routing is used in many industries for the production of finished parts and production components. Here are some specific applications of CNC routing:

- Wooden Furniture

- Signage

- Molds for Thermoforming

- Cabinetry and Millwork

- Prototyping and Product Development

- Engraving and Personalization

- Automotive and Aerospace Components

Additional Services From Rapid Manufacture

Below are some of the additional complementary services we offer to enhance your project.

Prototyping and Fabrication

The Rapid Manufacture team offers prototyping services and a dedicated in-house fabrication department to meet clients’ unique application needs. From packaging to product design, we manufacture with quick turnarounds and guarantee superior quality in everything we do.

Warehousing & Fulfillment

The Rapid Manufacture team offers the most efficient and cost-effective delivery service. We can then ship to you or directly to your customer. Our warehousing and fulfillment services are safe, secure, and inexpensive.

Ready to use CNC Routing Services for production components?

With a dedicated team of experts and a fleet of high-performance equipment, we’re ready to make your ideas a reality. To learn more about our top-of-the-line CNC routing services, contact us today.