CNC Milling Service

Our CNC milling process produces custom prototypes and end-use production parts in as fast as 1 day. We use 3-axis milling and 5-axis indexed milling processes to manufacture parts from more than 30 engineering-grade plastics and metals.

Expert CNC Milling Service

Utilizing the most up-to-date CNC milling machines, our CNC milling service is an excellent solution for creating parts featuring complex shapes and high dimensional tolerances while providing a cost-effective solution for short production runs. CNC precision milling can produce virtually any 2D or 3D shape where the rotating cutting tools can easily reach the material.

Rapid Manufacture is your reliable partner for obtaining parts with unique or complex shapes. Our custom CNC milling services are tailored to your specifications, ensuring precision. With expertise in three-axis and five-axis milling, we are well-equipped to handle your manufacturing processes or metal fabrication needs. Whether you need a prototype or a fully functioning product, we will deliver quickly and efficiently, helping you meet even the most demanding production schedules.

CNC Milling Quote Online

We support 3-axis, 4-axis, 5-axis milling, and right angle milling capabilities to help you rapidly create designs from simple straight lines to complex geometric shapes. Rapid Manufacture offers instant pricing, on-demand lead times, and design-for-manufacturability feedback on materials and manufacturing processes for your custom CNC milled parts, no matter your industry. Just upload your CAD files onto the platform to get an instant quote and lead time for your CNC parts. After confirming, we take care of the manufacturing side of things, using state-of-the-art machinery.

Our CNC Milling Services

Our CNC machining capabilities include both 3-axis, and 5-axis mills:

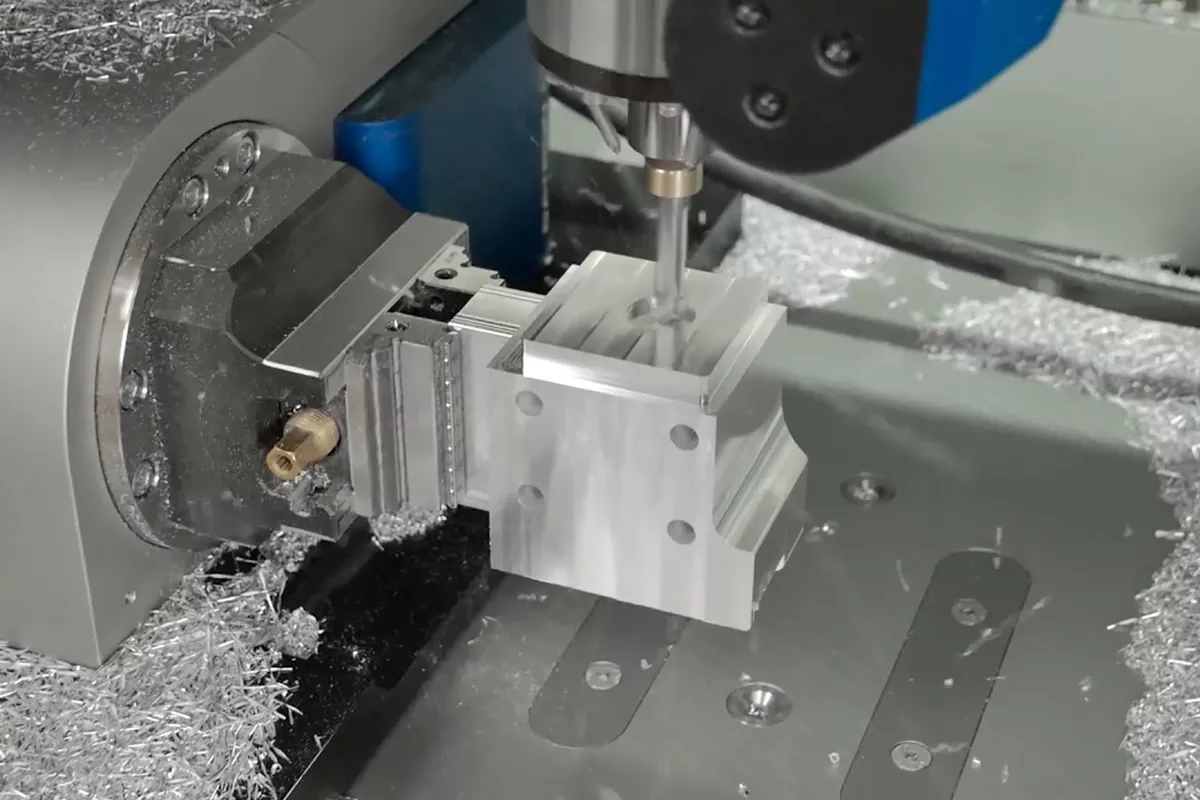

3 Axis CNC Milling

A profitable and efficient solution to your CNC milling needs! We ensure the machining of parts with complex geometrical shapes, including undercut features, threaded holes, sharp edges, and planar profiles. Complete multiple operations through effective integration with an automatic tool changer. We can also design 3-axis milling centers to meet the unique requirements of each client.

4 Axis CNC Milling

Get more complex CNC milled parts with our 4-axis CNC milling. We consistently produce precise and accurate results, with greater control and more flexibility, even with complex shapes. Ensure cost-effective machining of angled features that are rather impossible with 3-axis machines. With more power, greater control, and higher precision, 4-axis milling is your ideal solution.

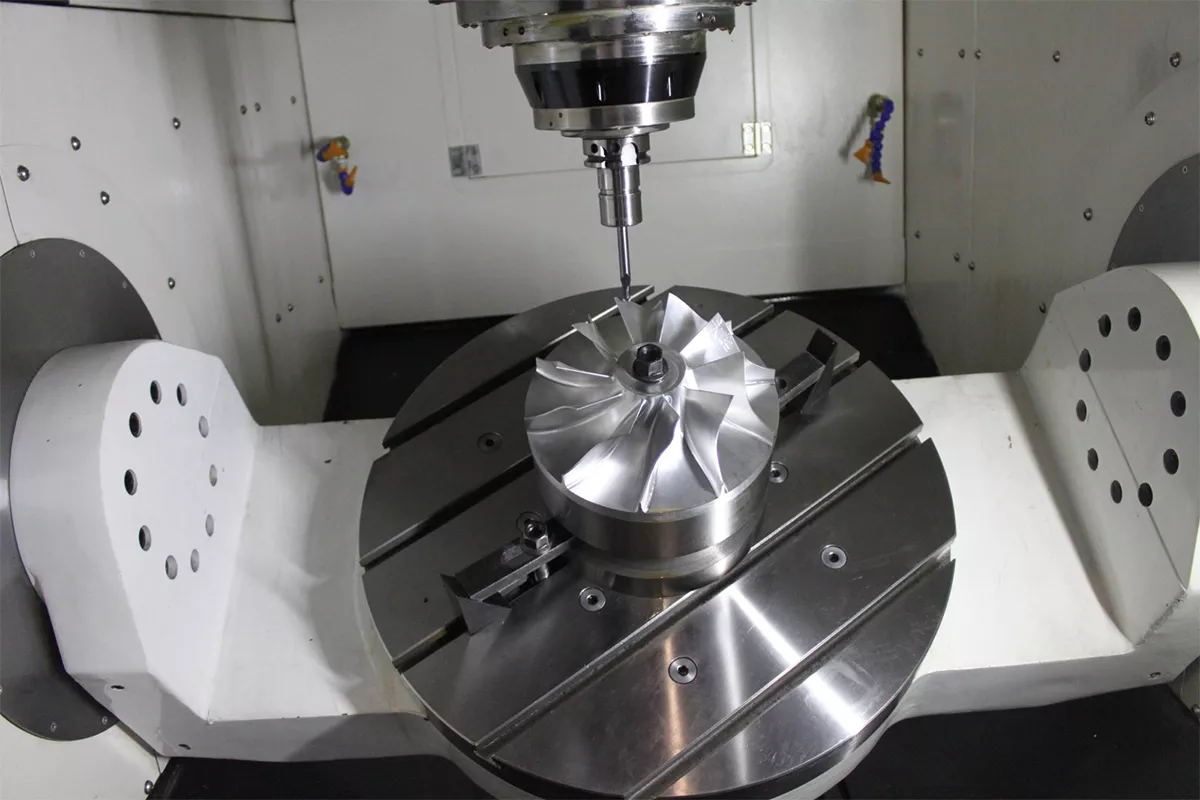

5 Axis CNC Milling

Machine complex custom CNC milled parts with a single setup. Our 5-axis CNC milling machines save time, improve efficiency, and reduce cost, ensuring that you meet market demands faster and cost-effectively. We can reach higher cutting speeds without excessive pressure on the cutter. Get rapid prototypes and low-volume production parts with better surface finishes.

Ready to Make Your Parts With Rapid Manufacture?

Use our quoting platform for quick quotes on production parts and prototypes.

What is CNC milling?

CNC milling is a computer-controlled subtractive machining process that uses rotating cutting tools to remove material from a solid, stationary workpiece to create custom-designed parts. During milling, the workpiece is cut along multiple axes to obtain a variety of shapes and geometries.

Our CNC milling services are simple: upload your CAD files to our Instant Quotation platform, work with us to optimize your design and select your materials, then get your project into production quickly and efficiently.

CNC Milling Applications

From single, speciality parts to full production runs, CNC milling can be used to create a variety of industrial parts with applications that include:

Tooling

Manufacture parts with complicated cuts and different angles using a variety of cutting, drilling, and lathing tools.

Niche manufacturing

CNC milling is capable of creating a range of niche, durable metal or plastic products that alternative manufacturing processes cannot.

Medium-to-high-volume production

The CNC milling process is particularly useful for high-volume manufacturing runs, offering automated speed and cost benefits.

Metal fabrication

CNC milling is a safe, effective way of creating high quality metal parts with exceptional tolerance levels.

Hybrid manufacturing

CNC milling is not just a process suited to working with metals: molded and 3D printed parts can also be machined.

Rapid prototyping

The CNC milling process is fast, automated, and useful for the production of prototype parts.

CNC Milling Tolerances & Standards

| Description | General Tolerance or Standard |

|---|---|

Maximum Part Size | Milled parts up to 80” x 48” x 24” (2,032 x 1,219 x 610 mm). |

Distance Dimensions | For features of size (Length, width, height, diameter) and location (position, concentricity, symmetry) +/- 0.005”. |

Orientation and Form Dimensions | 0-12″ +/- 0.005″, Angularity 1/2 degree. For 24″ and beyond please consult Rapid Manufacture’s Manufacturing Standards. |

Precision Tolerances | Rapid Manufacture can manufacture and inspect to tight tolerances, including sub +/- 0.001″ tolerances, per your drawing specifications and GD&T callouts. |

Minimum Feature Size | 0.020” (0.50 mm). This may vary depending on part geometry and chosen material. |

Threads and Tapped Holes | Rapid Manufacture can accommodate any standard thread size. We can also machine custom threads; these will require a manual quote review. |

Surface Finish | The standard finish is as-machined: 125 Ra or better. Additional finishing options can be specified when getting a quote. |

Edge Condition | Sharp edges will be broken and deburred by default. Critical edges that must be left sharp should be noted and specified on a print. |

CNC Milling Materials

We stock more than 30 production-grade plastic and metal materials that are suitable for various part applications and industries.

Plastics

- ABS

- Acetal

- CPVC

- HDPE

- LDPE

- Nylon

- PEEK

- PEI

- PET

- PMMA

- Polycarbonate

- Polypropylene

- POM (Delrin)

- PPSU

- HIPS

- PSU

- PTFE

- PVC

Metals

- Aluminum

- Brass

- Copper

- Stainless Steel

- Alloy Steel

- Steel Mild Low Carbon

- Titanium

Advantages of CNC Milling

Using the latest CNC machining capabilities, Rapid Manufacture produces highly accurate, quick turn parts in as fast as 1 day. We also instantly quote CNC machined parts, cutting days off of your RFQ process.

Offers high-precision tolerances, including sub +/- 0.001″ tolerances. We are the experts in making parts that are truly custom and ready to use.

CNC machining processes are perfect for prototyping and production CNC parts. Rapid Manufacture ‘s massive scale can help you scale up from testing phase to production runs of 100,000 parts of more.

Choose from over 50 metal and plastic materials. CNC Machines offer a wide variety of certified materials.

Surface Finishes for CNC Milling

Gain access to quality surface finishing for custom CNC milling parts to remove aesthetic flaws and improve the appearance of your products. We also provide rigid protection and additional resistance and strength to your parts through superior surface finishes.

- Bead Blasting: Bead blasting adds a satin or matte finish to a CNC part. The matte finish is accomplished by using a pressurized air gun to shoot glass beads at a part.

- Powder Coating: Following powder coating, the part has a thin protective layer that adds strength and wear-resistance. During the powder coating process, the part is first primed using a chromating or phosphating coat. Next, the part receives a dry powder coating from an electrostatic spray gun. Lastly, the part is cured in an oven.

- Anodizing: Once a CNC part has been anodized, it has an oxide layer that increases its density, thickness, and durability. Anodization also makes a part electrically non-conductive. During the anodizing process, the part is placed into an acid electrolyte bath which serves as an anode. A cathode is added to the part, and an electrical current is passed through the acid. Oxygen ions from the electrolyte and atoms from the alloy are combined along the surface of the part.

- As-Milled: As-milled or as-machined products do not require a secondary process. They will still have visible blemishes and may have a rough surface.

- Surface Grinding: Surface grinding produces a smooth finish. Surface grinding removes material by using a high-speed abrasive wheel as a cutting tool. The surface grinding process is used when a specific size or precision finish is required.

- Painting: Painting a part adds color, varnish, or ink. The painting process may include powder coating, liquid coating, or e-coating. Powder coating uses an electrostatically charged powder which produces a scratch-resistant and uniform coat on the metal part. When a part is liquid coated, wet paint is applied. The e-coating process involves dipping the part into a bath of paint where both the part and paint are electrified, causing the paint to adhere to the part.

- Polishing: Polishing improves the dimensions and accuracy of a part while producing a mirror gloss finish. Polishing tools and abrasive materials are used to achieve a smooth surface.

- Passivate: After a CNC machined part has completed the passivation process, its corrosion resistance is improved. Passivation may include spray application, circulation in a chemical solution, gel application, or tank immersion.

- Chemfilm: Chemfilm finishing is a chemical conversion coat that adds corrosion resistance to aluminum substrates, acting as a base for organic coatings. The part is dipped, brushed, or sprayed with the chemfilm layer.

- Vacuum Metallization: The vacuum metallization process adds a mirror-like or decorative uniform finish while also improving thermal, air, light, or water barrier properties. In the vacuum metallization process, the part is placed inside a closed chamber where a metal vapor adheres and coats the part.

- Silkscreen: Screen printing is used to transfer a design or logo to a part. When a part is silk-screened, a mesh is used to apply ink onto the surface, but only to permeable areas that are not covered by a blocking stencil.

- Plating: Plating results in corrosion and abrasion resistance, conductivity, and reflectivity to parts. While electroplating, the part is submerged into an electrolyte bath with the material that will be used for the metal coating. An electrical charge causes the material to transfer to the part, resulting in a uniform metal coating.

- Tumbled: Tumbling or ultrasonic polishing removes any sharp points or edges from a machined part. During the tumbling process, the part is placed inside a barrel along with media, water, and detergent. The barrel tumbles at different speeds depending on the desired finish.

Our CNC Milling for Various Industrial Applications

CNC milling parts have seen significant use in a variety of industries. With our advanced facilities and refined CNC milling technologies, we can create precision and quality CNC milled parts in a rapid manner.

Energy

Image Accordion Content Goes Here! Click edit button to change this text.

Difference between CNC milling and CNC turning

CNC milling and turning both are capable of producing accurate custom parts from metals, plastic and other materials. The main difference is that while the cutting tools rotate for milling, the raw material rotates for turning. For that reason, turning is mostly used for machining custom cnc round parts such as shafts, pins, balls, etc. Another difference is that while basic milling machines have three axes of motion, a lathe or turning machine needs only two. In a mill, the cutter usually moves up and down while the workpiece moves horizontally in two directions. In comparison, turning requires only that a non-rotating cutter move left and right on one hand and forward and back for the second axis. The fact that turning has only two axes in its simplest form, constrains the variety of shapes it can produce. For example, turning can produce a shaft, chess pawn, a cylinder with a rounded end, etc. Turning normally can’t produce even a simple enclosure box. However advanced turning centers can have more than two axes and therefore can produce a wider variety of shapes.

Ready to get started on your CNC milling quote?

Our CNC milling services allow you to create industrial-grade parts and components with automated speed and precision.Let’s Start A New Project Today