5 Axis CNC Machining Service

5-axis CNC machining is a powerful manufacturing solution, get high-precision, accurate, complex machined parts with extremely complex geometries with the help of our 5-axis CNC machining services. Competitive pricing and quick turnaround.

5-Axis CNC Machine Shop Services With Ultra Precision

With 5 axis machining services, we can machine extreme precise and accurate complex geometries . For parts with extremely complex and multi-faceted designs, our advanced five-axis machines can perform efficient and flexible machining through five-axis linkage,allowing a shorter, stronger cutting tools to improve stability, stay precision and achieve good surface quality. Rapid Manufacture provides 5 axis CNC machining parts for global customers in China, industries fields covering aerospace, automotive, shipbuilding, machinery, medical, energy, electronics and other industries. Whether it is metal or plastic materials, whether it is prototyping or small batch production, our factory’s advanced equipment can meet your needs. We have the machining capability to achieve precision up to 0.002mm tolerance, and can provide a complete test report. You can rest assured to entrust the project to us.

5 Axis CNC Machining Capabilities

Rapid Manufacture’s 5-axis machining services offer unparalleled speed and flexibility. With a wide range of advanced 5-axis CNC machines and a wide range of materials, we are capable of delivering the best in 5-axis machined parts. Our experienced team and manufacturing capabilities help quickly design and manufacture complex, time-sensitive components. With world-class equipment, expertise and experience, Rapid Manufacture uses two exceptional setups to deliver precise, complex parts.

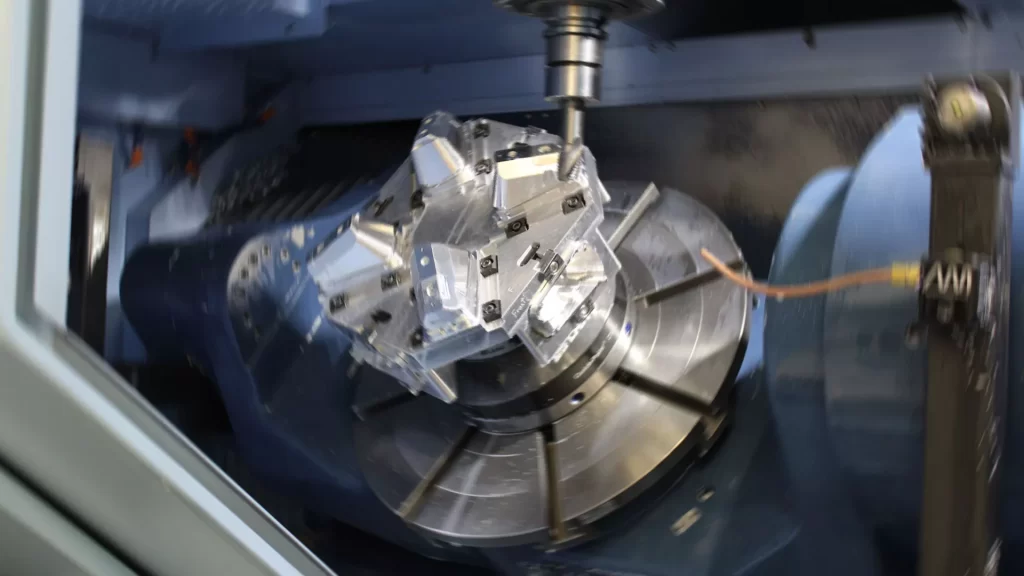

5-axis Simultaneous Machining Service

Our 5 axis machining services center, which can continuously adjust the movement of five axes without interruption,is fast, effective and continuous in machining, enabling the transition improvement and surface quality assurance. without putting undue stress on the tool,our 5-axis simultaneous machining can achieve faster cutting speeds ,and get complex shape prototypes and low-volume end-use parts with better surface finish.

3+2 axis CNC machining service

Using our fixed axis machining service methods,we can get complex CNC machined parts with tight tolerances at lower cost and shorter cycle times. Axis holding the part in a specific orientation for milling so that we can use 3-axis machining to process the parts, and use a shorter but stronger cutting tools at the same time,enabling us to provide a greater dimensional stability.

Customized online five-axis CNC machining services

Our rapid five-axis CNC machining capabilities include metal and plastic services and flexible production and shipping options to meet your needs at the perfect price and product development stage.

Looking for great 5-axis CNC services? Upload your design files to our online platform and get an instant CNC machining quote in seconds. Our platform also provides you with free DFM analysis reports to help you get the most out of your project. From quote to delivery, you’re in complete control.

Quickly Get Custom Parts In 4 Easy Steps

Upload your CAD files

Upload your design files directly or send your project information via the quote page. All files are supported by NDA.

Quotation and DFM Analysis

We will respond to your inquiry within 12h and will send back a design for manufacturability analysis and a real-time quote.

Start of production

The order is confirmed, we will start the manufacturing process based on your CAD design with quality assurance.

Receive your parts

Prototypes or parts will be produced within a few days and delivered directly to you via international courier.

Quality Assurance

- Quality System Certification ISO9001:2015 obtained since 2015.

- Strict quality controlflow: IQC(Incoming Quality Control), FAI (First Article Inspection), IPQC(InPut Process Quality Control), OQC(Outgoing Quality Control) and COC (Certificate of Conformance) can be provided at your request.

- Rich Inspection Ways and Inspection tools, like pin gauge, colorimeter etc.

- A wide range of inspection equipment: CMM, Flash Measuring Machine, 3D Scanner, 2D Image Measuring Machine, etc.

- Highly-skilled QA team with over 10-year experiences.

- Strict Quality Control System to keep processes improvement and optimization.

- Material certificates and test reports can be provided on request.

Why choose Rapid Manufacture for 5 Axis CNC Machined Parts?

Combined with our rapid response rate and excellent customer service, our clients value our experience and approach for their precision manufacturing needs. With dependable 5 Axis machining services, Rapid Manufacture can help you carry your project forward, with the capability for a vast amount of bespoke manufacturing projects and machining needs.

Rapid Manufacture is ISO 9001 certified. This certification recognises our attention towards delivering high-quality parts and we continually strive to improve our services to make your experience as straightforward as possible.

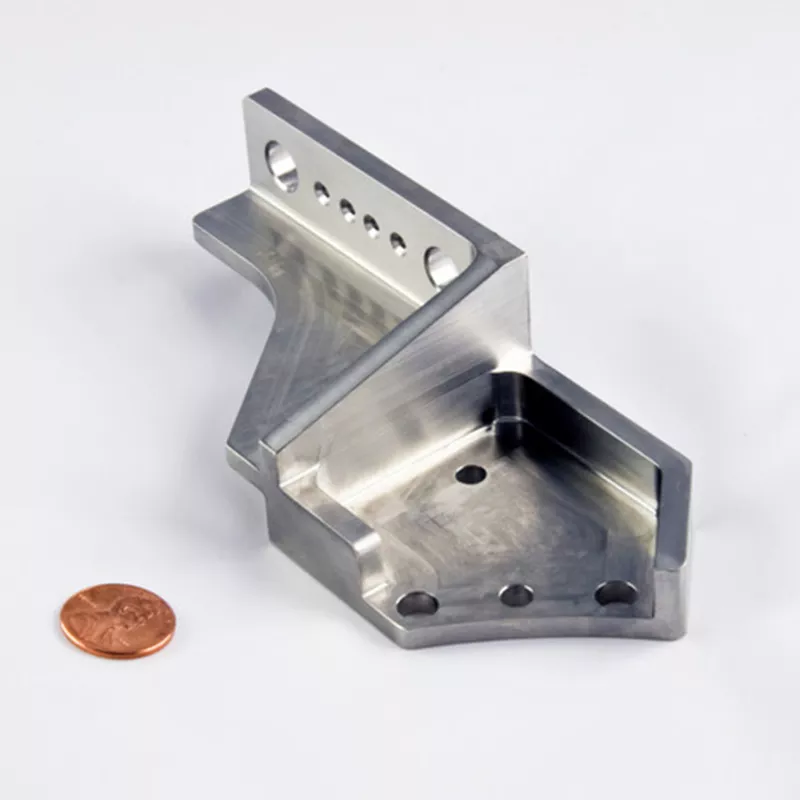

5 Axis CNC Parts are often bespoke, intricate and complex parts. With over 20 years of experience in delivering project-critical, precision machined parts for a wide range of industries, you can trustRapid Manufacture to deliver.

Gallery of CNC Machined Parts

5-Axis Machining Materials

Rapid Manufacture has extensive experience manufacturing component parts from different materials using 5-axis machining:

Aluminum is a highly ductile metal, making it easy to machine. The material has a good strength-to-weight ratio and is available in many types for a range of applications.

Copper displays excellent thermal conductivity, electrical conductivity and plasticity. It is also highly ductile, corrosion resistant and can be easily welded.

Brass has desirable properties for a number of applications. It is low friction, has excellent electrical conductivity and has a golden (brass) appearance.

Stainless steel is the low carbon steel that offers many properties that are sought after for industrial applications. Stainless steel typically contains a minimum of 10% chromium by weight.

Titanium has a number of material properties that make it the ideal metal for demanding applications. These properties include excellent resistance to corrosion, chemicals and extreme temperatures. The metal also has an excellent strength-to-weight ratio.

An iron and carbon composition with other elements intentionally added, including manganese, chromium, vanadium, nickel, or tungsten. Alloy steels are typically divided into two categories: high alloy and low alloy.

An alloy comprised of copper and tin, it offers a wide range of properties such as high ductility, hardness, thermal conductivity, strength, and workability. Bronze is often used to manufacture nuts, bolts, threaded parts, bearings, bushings, screws, and more.

A metal alloy of carbon and steel, but could also contain nickel, copper, or manganese. Carbon steel is commonly used for axles, gears, shafts, rails, pipelines, couplings, and more.

A strong nickel-chromium-iron-molybdenum alloy that is resistant to corrosion. Hastelloy steel is often used to manufacture contour rings, rings, hubs, flanges, shafts, and other manufactured products.

What finishes are available for 5 Axis CNC Machining?

Surface roughness can be specified using Ra value. Ra3.2 – 1.6um as standard.

Bead blast size: 80um as standard. 50-120um available.

Standard: Clear / natural, black, red, green, blue, yellow / gold. Close match to specified RAL numbers.

Standard: Black or Grey. Much duller in look, but has much better surface protection.

Let's Start A New Project Today

What is 5-axis CNC Machining ?

5-axis CNC machining can produce parts with complex geometries and increase productivity by reducing the number of machine setups. It allows the rotation of the machine bed or the tool head (or both) and the three linear axes of movements. It is extremely suitable for deeper parts made from harder materials, and it guarantees a high degree of precision due to using shorter machining tools. The machining speed is also faster, while tool vibration is reduced.

Why Do Manufacturers Use 5 Axis CNC Machining?

There are several advantages to 5-axis machining over traditional 3 and 4-axis CNC machining.

The key advantage is that it allows you to machine at many angles in a single setup. Typically, complex parts would have to be milled with multiple machines or setups, as a single 3-axis machine does not provide the same level of access to all sides of the part as a 5-axis machine does.

With the ability to tilt and rotate the workpiece and cutting tool, 5-axis CNC machines offer greater flexibility in accessing various sides and angles of the workpiece. 5-axis CNC machines allow the cutting tools to easily reach intricate features, undercuts, deep pockets, and other difficult-to-machine areas of the workpiece.

This means you don’t have to re-clamp or re-fixture the workpiece, improving the overall efficiency of your processes.

Another typical use of the extra axes is to machine sloped/angled surfaces or planes, a task which is much more challenging to perform with a 3-axis CNC machine.

Our 5 Axis CNC Machining for Various Industrial Applications

Rapid Manufacture works with leading manufacturers from different industries to support growing demands and streamline their supply chain. The digitalization of our custom CNC machining services helps more and more manufacturers bring their idea to products.

Get multiple quotes for your parts in seconds

Our 5 Axis CNC Machining Services make up part of our wider precision engineering service offerings. We work with customers within the energy, medical, automotive, and aerospace industries, to name just a few. The Rapid Manufacture team continues to invest in the latest technologies, looking to boost efficiencies, manufacturing capabilities and output, increase productivity and accuracy of machining, whilst lowering costs and production lead times for our customers with often strict requirements.