Introduction to PEEK in Medical Implants

Understanding PEEK’s Potential for Medical Use

PEEK’s exceptional properties make it ideal for medical implants. Its biocompatibility ensures integration with human tissues, while its mechanical strength suits long-term stability. PEEK’s radiolucency enables clear imaging for monitoring. Used in spinal, orthopedic, and dental implants, PEEK revolutionizes medical implant technology.

In this context, understanding PEEK’s potential for medical use is crucial for unlocking new possibilities in implant design, enhancing patient outcomes, and advancing the standards of healthcare.

Advantages and Applications

Why PEEK? Exploring Its Benefits in Medical Implants

Polyether ether ketone (PEEK) stands out as a preferred material for medical implants due to its remarkable advantages. Its unique properties make it a versatile and reliable choice for a wide range of implant applications.

PEEK’s biocompatibility ensures seamless integration with human tissues, reducing adverse reactions and enhancing patient safety. Its exceptional mechanical properties, including strength and flexibility, make it ideal for long-term stability in implants. PEEK’s radiolucency enables clear imaging for post-implantation monitoring, facilitating accurate assessment and effective patient care.

The numerous advantages of PEEK make it an ideal material for medical implants.

Where It Works: PEEK’s Versatility in Different Implant Types

Polyether ether ketone (PEEK) emerges as a standout choice for various implant types, showcasing its remarkable versatility and adaptability across different medical applications.

PEEK’s exceptional mechanical properties make it ideal for spinal implants like fusion devices, cages, and rods, while its radiolucency aids accurate post-surgery assessment. In orthopedic implants, PEEK’s biocompatibility and strength support bone integration in joint replacements, fixation plates, and screws. PEEK-based dental implants offer durability and aesthetics, reducing inflammation risk. Additionally, PEEK is versatile, used in craniofacial and cardiovascular implants.

Its widespread adoption underscores its significance in advancing healthcare solutions and improving patient outcomes.

Addressing Challenges and Innovations

Overcoming Hurdles: Improving PEEK for Medical Use

While polyether ether ketone (PEEK) offers numerous benefits for medical applications, certain challenges persist, prompting ongoing innovations to enhance its suitability for medical use.

One primary challenge for PEEK is its hydrophobicity, hindering bone integration. Researchers explore surface modifications to enhance bioactivity and tissue integration. PEEK’s radiolucency poses challenges in imaging, especially in spinal implants. Additive manufacturing innovations aim to incorporate radiopaque materials for clearer imaging. Further enhancements in mechanical performance are pursued through composite materials and hybrid structures, combining PEEK with reinforcing agents like carbon fibers. Efforts to broaden PEEK-based medical devices include optimizing manufacturing processes and advancing 3D printing for complex geometries and personalized implants.

By addressing these challenges and driving innovations, researchers and manufacturers aim to maximize the potential of PEEK for medical use, paving the way for improved patient outcomes and enhanced healthcare solutions.

Regulatory Approval and Clinical Trials

Getting the Green Light: PEEK in the Eyes of Regulations

Polyether ether ketone (PEEK) holds great promise in medical applications, but before its widespread adoption, regulatory approval and clinical trials are essential steps to ensure its safety and efficacy.

Regulatory bodies like the FDA in the US and EMA in Europe rigorously evaluate PEEK medical devices for compliance with biocompatibility, mechanical performance, and manufacturing standards. Clinical trials assess safety and efficacy in real-world settings, crucial for regulatory approval. Adhering to Good Manufacturing Practices ensures quality and consistency throughout production. Meeting regulatory requirements and demonstrating safety through trials are vital for PEEK’s market approval, advancing healthcare solutions.

Sustainability and Environmental Responsibility

The Eco-Friendly Side: Assessing PEEK’s Impact on the Environment

As the healthcare industry increasingly focuses on sustainability, assessing the environmental impact of materials like polyether ether ketone (PEEK) becomes crucial. While PEEK offers numerous benefits in medical applications, understanding its eco-friendliness is essential.

PEEK’s production involves high energy consumption and non-biodegradability, raising environmental concerns. However, compared to metal implants, PEEK’s lighter weight reduces transportation emissions during surgery. Efforts to mitigate its impact include recycling programs and bio-based alternatives, reducing waste and conserving resources. PEEK’s durability minimizes replacements and medical waste. Advanced manufacturing techniques optimize material usage, further reducing waste.

While challenges remain, ongoing research and innovation aim to enhance the sustainability of PEEK in medical applications. By addressing environmental concerns and promoting eco-friendly practices, the healthcare industry can maximize the benefits of PEEK while minimizing its ecological footprint, ensuring a greener and more sustainable future.

Conclusion: PEEK’s Promise in Medical Innovation

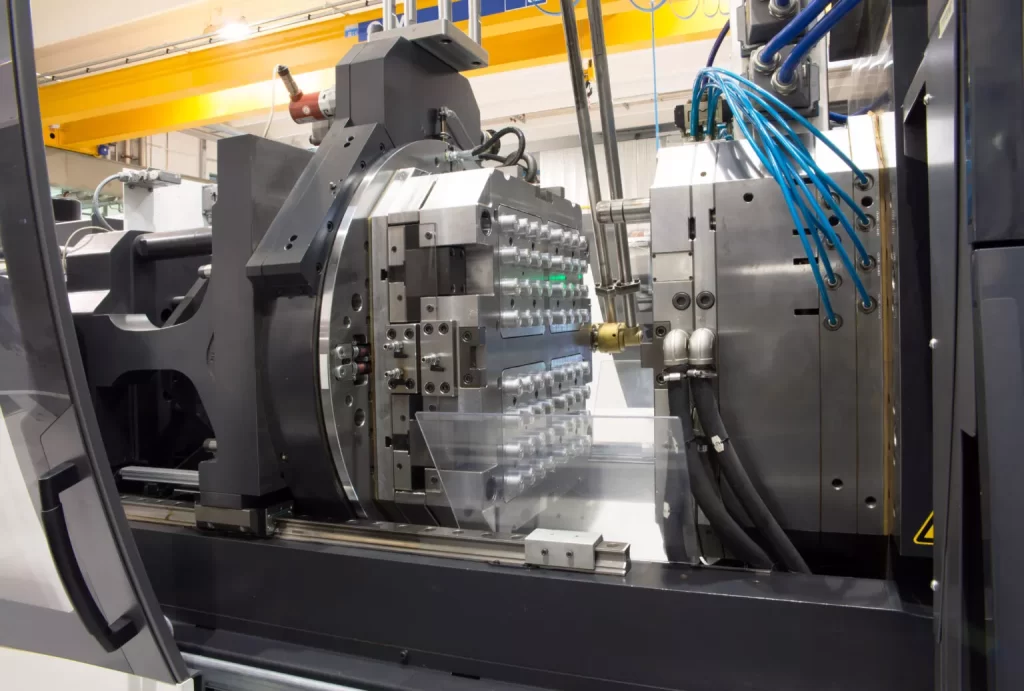

Precision Mold Manufacturing: Unlocking the Potential of PEEK Implants

PEEK emerges as a game-changer in medical innovation, offering promise in advanced implants. Precision mold manufacturing ensures high-quality, customized implants for spinal, orthopedic, and dental needs. PEEK components set new standards for excellence with superior biocompatibility and mechanical strength. Leveraging this technology will revolutionize healthcare, improving outcomes and promoting sustainability.

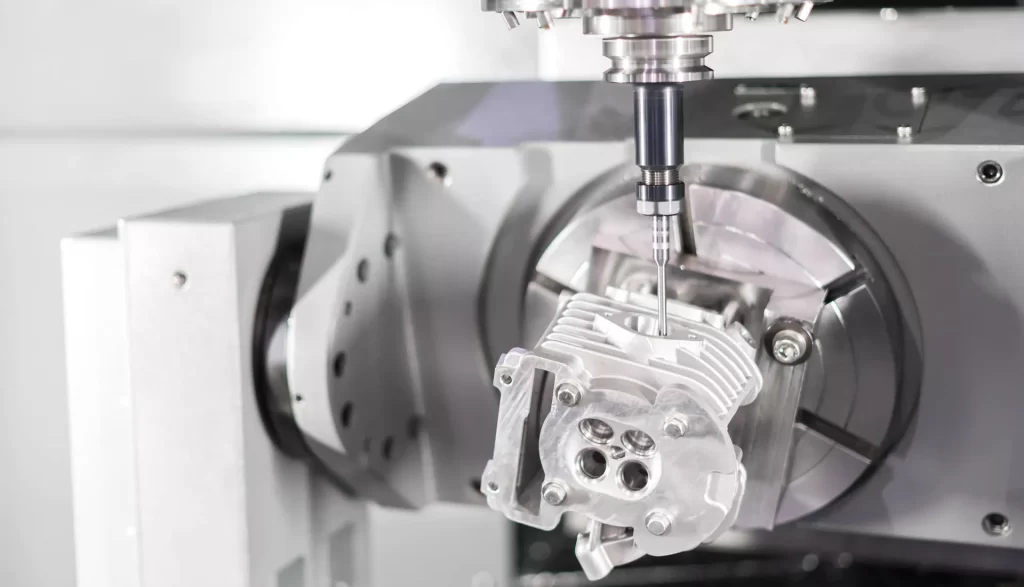

Craftsmanship with CNC: Leveraging Advanced Technology for Optimal Results

PEEK stands at the forefront of medical innovation, offering tremendous potential in groundbreaking implants. Craftsmanship enabled by CNC technology maximizes PEEK’s benefits. CNC ensures precise implants meeting exact specifications for optimal performance. Customization reduces complications, while superior mechanical properties and surface finishes enhance longevity and outcomes. Leveraging CNC technology will drive healthcare advancements, revolutionizing treatments and improving patient lives globally.

Partner with Us: Experience the Precision Advantage in Healthcare Innovation

The potential of polyether ether ketone (PEEK) in medical innovation is vast, offering transformative solutions in the development of advanced implants. At the core of this promise lies precision, and we invite you to partner with us to experience the precision advantage in healthcare innovation.

Through our expertise in precision manufacturing and advanced technologies like CNC machining, we are dedicated to unlocking the full potential of PEEK in medical applications. Our commitment to precision ensures that every PEEK implant we produce meets the highest standards of quality, reliability, and performance.

Experience the precision advantage in healthcare innovation by partnering with us. Together, we can harness the promise of PEEK to drive advancements in medical treatments, improve patient care, and shape the future of healthcare. Contact us today to learn more about how we can collaborate to realize the full potential of PEEK in medical innovation.