In the healthcare industry, medical molds have gained significant attention for their repeatability, and performance. These molds effectively produce sterilized, and consistent quality products for various medical use applications. From orthopedics parts to implantable devices, medical molds play a crucial role in part fabrication. Therefore, it’s crucial to preserve these molds for a longer time frame to increase their serviceability.

However, one can’t predict the exact life span of medical mold. But by following maintenance SOPs, you can keep using injection molding molds for a long period. This article provides valuable insights on mold maintenance and helps you sustain molds for optimal performance and a long life cycle.

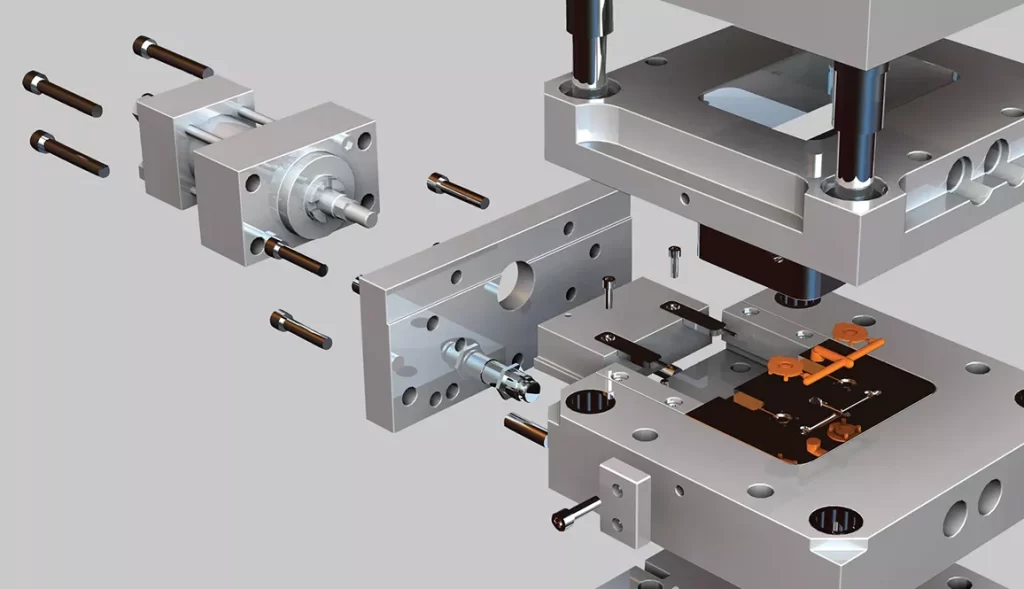

What Are Medical Molds and Where Are They Used?

Medical molds help replicate various medical use parts to fulfill patient needs. Injection molding molds, on average, can accommodate 250,000 cycles but can handle only around 180,000. This significant falling can be predicted from improper usage of mold or inefficient mold itself.

Medical molds produce stringent quality medical prototype parts by adhering to stringent FDA standards. These molds use medical grade thermoplastics; for instance, ABS, nylon, polyethylene, acrylic, and Delrin. The healthcare professional benefits from medical injection molding molds by producing antibacterial high quality devices for implants, and orthopedic use. For this reason, it’s key to maintain their hygiene, and optimal performance for enhancing mold’s longevity.

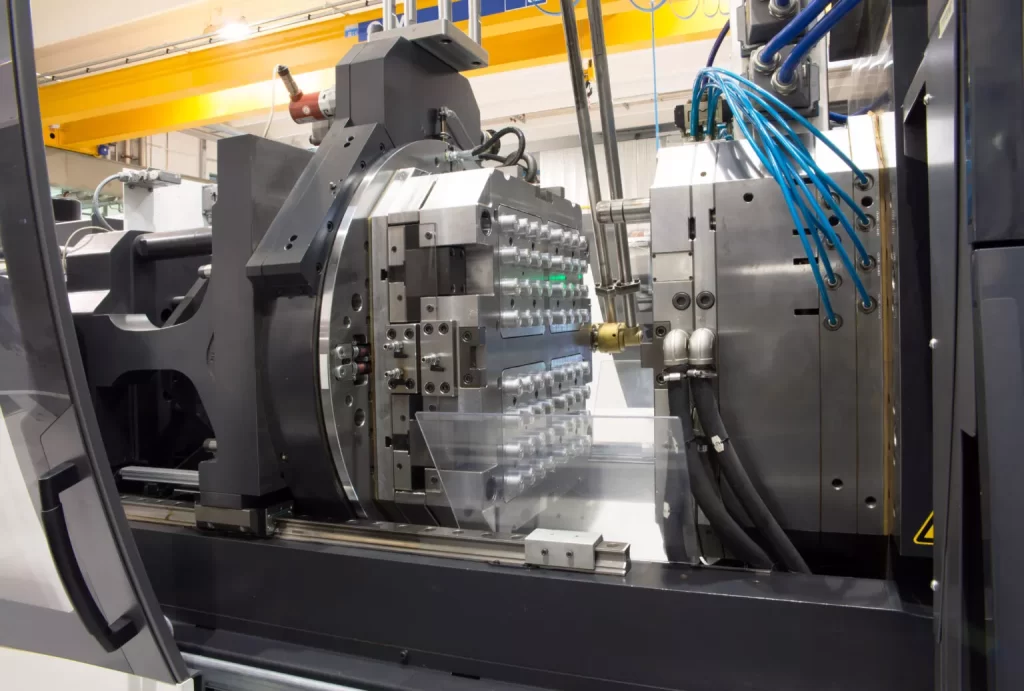

SPI Standards Classification of Injection Mold

The Society of Plastics Industry (SPI) helps manufacturing sectors by introducing SPI standards to identify mold types, their capabilities in terms of cyclability, and hardness bearing abilities. Here are some of these standards;

Table: SPI standards of Injection mold life cycle expectancy

| SPI Class | Capabilities | Hardness Values | Life Cycle Expectancy |

| 101 | Low cost mold, suitable for extremely high volumes | 28 RC, for tool components, and 48 RC, for cavities | 1 million |

| 102 | Moderate cost, suitable for high production volumes | 50-55 HRC | 500,000 to 1 million |

| 103 | Suitable for medium production volumes | 18 RC for tools, and 28 RC for cavities, and cores | 500,000 cycles |

| 104 | For low volume manufacturing projects | 60-65 RC | 100,000 cycles |

| 105 | Molds reserved for prototype production | 65 – HRC | 500 cycles |

Factors Impacting Mold Life Cycle:

Certain factors influence the cyclability of mold. Let’s evaluate these factors in brief detail;

Environment:

The serviceability factor of molds is greatly impacted by surrounding environments. It directly influences the intended part being molded into the product. The highly acidic, and harsh environments lead to inefficient molding and reduce serviceability to a great extent. Contrarily, a clean, and immaculate environment enhances mold’s lifespan and helps sustain it for decades.

Mold Material:

The mold material decides the longevity, and durability of the mold. Usually, OEM designers employ hard grade materials to shape molds for instance aluminum, and steel is frequently used metals for medical molds. These molds can be worn by plastic materials being used in shaping medical products. The hardness of the material dictates mold life. For example, aluminum is relatively softer than steel. Therefore, it has a longer life than a hard steel mold. Moreover, mold’s intrusive impurities sometimes greatly impact their service life.

Proper Maintenance:

The appropriate maintenance helps increase the longevity, and durability of molds. It’s a proactive approach to keeping healthy and enhancing mold life by ensuring proper function time by time. This way, it’s important to give rest to mold equipment between its running time to increase its durability. After every cycle let the mold cool down, reducing the heat element. Continuously using the equipment will lead to potential damage, and result in inefficient mold performance.

Mold Service Treatment:

To avoid overheating and cracking, focus on smooth transition and grinding techniques in mold cutting. To achieve a smooth and even surface it is important to emphasize plastic quality, demolding requirements, and erosion rust resistance.

Proper mold designs:

Designs can lead to a vast variety of qualities like engraving or identifiers making it essential for traceability in medical devices. A good mold design can contribute to the success of the product. Best designs will reduce stress input allowing the instrument to work for a longer time.

Maintaining a clean release:

Some part design features can often cause high ejection force. Polishing mold cavity features will be beneficial as it will reduce the coefficient of friction and result in lower ejection force, which is more preferred.

Precautionary Maintenance:

To prevent product imperfections and default one must take care of the equipment by ensuring that it is kept in good condition along with preventative maintenance that can improve tools to last longer.

Strategies for Productive Maintenance:

Various factors come in the way of proper maintenance for preserving molds for longer spans.

Mold structure and dimensions:

It is important to look out for the best designs as they play an important role in product management. Quality design includes elements such as reasonable flow length and minimum clamp requirements.

Surface treatment and processing:

It involves mold shaping into desired structures and dimensions to prevent overheating and cracking. This will lead to proficiency and their service life by enhancing their strength and hardness.

Immaculate and Examination:

Regular cleaning is a fundamental aspect of maintaining molds equipment as instant cleaning of contaminants and toxins on the mold surface will increase its service life. Inspection should be carried out after every use or production run to identify any kind of damage or wear and tear. This will reduce errors and faults if created by the equipment.

Lubrication:

Make sure to lubricate mold equipment from time to time to reduce thermal stress. Silicone-based lubricants are often used in the medical field, as it will reduce friction to its maximum extent. It is crucial to select a specific lubricant for your tool but once done it will be effective.

Temperature and Humidity Management:

Maintaining the ideal environment for medical mold devices is as important as its manufacturing. Fluctuations in temperature and humidity will lead to major changes in its dimensions and capability to work. A controlled environment with appropriate conditions will reduce surrounding stress and maximize its capability to perform and last longer.

Training and education:

Professional personnel should be hired when handling this equipment, as they are very delicate and critical. Training programs that include proper handling techniques, procedures, and safety precautions should be provided before implementation.

Regular maintenance:

Regular maintenance should be the routine of the mold equipment user. This schedule should include cleaning, lubrication, parts maintenance, and inspection. This will in turn increase the productivity of the equipment and ensure the patient’s safety.

Things to Remember To Ensure Your Mold Health:

- Use those products that are recommended for cleaning your tool for example CLR mold and mildew clear or RMR-86 Pro Instant Mold Stain.

- When you are not using the tool, make sure to store it at an optimal temperature which varies from 50°C – to 200°C depending on different mold classes.

- Carry out inspections almost every five days.

- Avoid using harsh chemicals as they can cause corrosion.

Common Inaccuracies That Will Affect Durability:

- Skin marks are small distortions present on the surface of mold caused by variations due to temperature changes.

- Wrapping occurs due to distortion or deformation after the ejection.

- Flash is the extra material that causes protrusion and interferes with working.

- Severe heating on specific parts of mold that will reduce durability causes burn marks.

- Bubbles and voids are air pockets that are trapped on the surface of mold decreasing its capability to work.

Wrapping Up:

Medical mold instruments play the most significant role in the medical field thus their maintenance is also necessary and if not done will reduce the capability, durability, and effectiveness of the tool. Implementing proper maintenance will help with device insecurity and minimize mold-related defects. Eventually, if you are investing in your tool maintenance, it will be the right investment that will not only safeguard its integrity but also enhance its functional performance..

FAQ’s

Q1. What is the life expectancy of a mold?

Molds often have a suitable life expectancy but if you invest in their maintenance and follow basic preservation tips, your mold can last longer than expected.

Q2. Why is it important to justify mold maintenance?

Maintenance is as important as its manufacture. Preservation of your tool will only help it to last longer, increase its durability, and reduce the need for costly repairs.

Q3. Why does mold need optimal temperature and the right amount of moisture?

If you want to increase the lifespan of your tool, temperature and moisture are the most basic maintenance you should keep an eye on. If the temperature and moisture are not managed, the equipment will lose its capability and show its proficiency 10 times less.