Rapid Prototyping and Production Industrial Equipment and Machinery

Meet the growing need for connected hardware while still supporting legacy equipment and machinery with custom parts

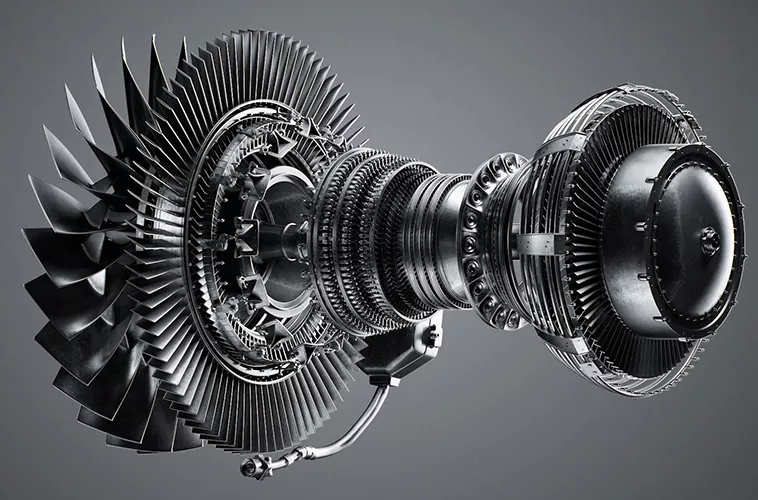

Accelerating Production of Industrial Equipment and Components

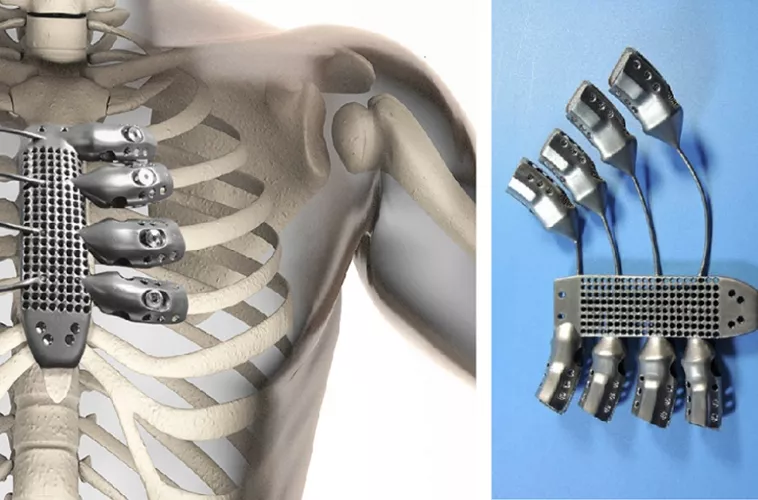

Industrial design prototypes bridge the initial conceptual and manufacturing production phases. Prototyping will be done iteratively with product design to ensure that the development process continues to perform as designed and expected.

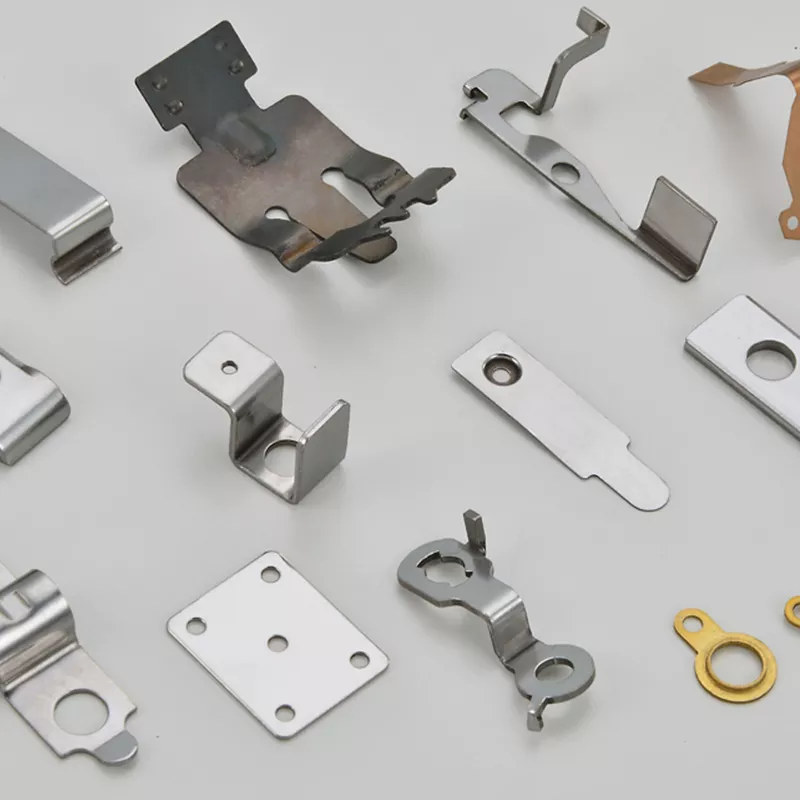

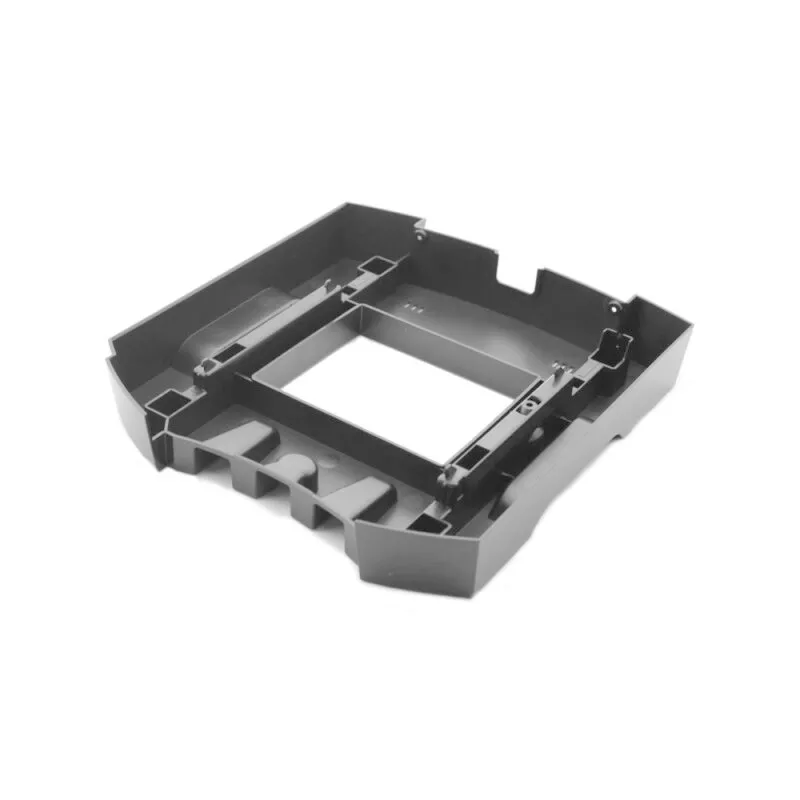

Rapid Manufacture utilizes metal alloys and hundreds of industrial-grade plastic materials, such as carbon fiber ceramics, to produce high-quality parts for industrial equipment and machinery. We offer cost-effective custom solutions for industrially related products such as machine and tool parts, electronic housings, pumps, and more. We can bring your ideas to life on time and within budget, from early prototyping to high-volume release.

What Is Industrial Design Prototyping?

As the pace of product design for industry increases, designers are pushing ahead with the bridge between concept and production in the fastest time possible. Industrial design prototyping is the first step in putting ideas and concepts in product design into practice, exploring solutions for product design manufacturability by moving designs into production-ready prototypes. Product design prototyping involves applications such as proof of concept, visual presentation, functional testing, engineering and production validation, and accurately communicates design intent, functional usability, material feasibility, and the working mechanism and performance of the product to manufacturers and product engineers.

Why work with us?

Manufacturing industrial equipment requires a thorough understanding of basic machining concepts and processes. Rapid Manufacture has the expertise and experience of a team of experts to help your business succeed in the industrial market. Our state-of-the-art technology allows us to provide the best manufacturing solutions at competitive prices and shorter cycle times.

Powerful Capabilities

Being an ISO 9001:2015 certified organization, we guarantee that your industrial equipment components are manufactured utilizing the most suitable materials and techniques, like CNC machining, sheet metal fabrication, die casting and more.

High Precision Parts

Rapid Manufacture specializes in custom manufacturing of industrial equipment parts that meet precise requirements. Our manufacturing capabilities enable us to produce industrial parts with tolerances as tight as +/- 0.001 inches.

Fast Cycle Time

Get quotes within minutes and parts within days! With high manufacturing skills and technical experience, our expert engineers will work to reduce cycle time by up to 50%.

Industrial Equipment Parts Manufacturing

Take advantage of top-notch industrial equipment manufacturing for high-quality industrial components and tools. Rapid Manufacture is the ideal partner for custom-manufactured industrial components with cutting-edge technology, advanced processes, and an intensive quality management system. A perfect blend of expert technicians and advanced technology ensures unique optimal results for every production results.

Free moldability analysis within hours

Precision Industrial Applications

- Jigs and Fixtures

- Housings and Enclosures

- Pumps and Accessories

- Oil and Gas Extraction Equipment

- General Industrial Machinery

- Conveyors and Conveying Equipment

- Parts for Tractors, Bulldozers, Forklifts, and Other Heavy Construction and Individual Vehicles and Equipment

- Sensors and Actuators

Custom Prototypes and Parts for Industrial Equipment Companies