Custom manufacturing of essential machine support components has seen various transitions over the years. Usually, custom manufacturing is done to incorporate the requirements of the growing industry. With advancements in the mechanical design sector for heavy machinery, supporting components such as sheet metal brackets need to be altered as well. Previously, most of the machines utilized a basic design for the support brackets but recently due to the novelty in design of support parts, customized manufacturing is required. Having said that, most of the support brackets for heavy machinery are made using sheet metal. Customized manufacturing of such components ensure that the design is precise and according to the requirements of the machine. The knowledge and understanding of how sheet metal brackets are manufactured is very important, therefore this article will be very useful for you.

Design Considerations

There are multiple factors that need to be kept in mind before going into the design stage for sheet metal brackets. These factors include the material strength, the load-bearing capacity, application, mounting options and placement of the brackets. These are the major factors that could alter the overall applicability of the bracket being manufactured. Another important consideration to be made is the thickness of the sheet being used for forming the metal bracket. Thickness is important in determining the structural strength and the failure stresses of the component.

Material Selection

Choice of material is basically the first step and it is subjected to change as per the required application. There are some crucial mechanical properties such as strength, stiffness, and toughness, that are capable of sustaining the applied loading on the bracket. Prevention of corrosion is also a crucial factor that needs to be taken into account to prevent material degradations.

Additionally, cost is a constraint which mainly controls the material and the manufacturing cost. Ductility and malleability are basic properties that the material needs to possess so that it can be formed into the required shape easily. Specifically for weight-sensitive applications, the strength-to-weight ratio needs to be high. Thermal resistance and ability to withstand environmental external conditions is also an equally important factor in material selection. Common materials used for custom manufacturing of sheet metal brackets include:

Steel: Steel offers high strength and durability, it is very effective for heavy applications.

Aluminum: In cases where the application does not involve heavier loads, aluminum can be used which can be an ideal case for weight-related concerns.

Stainless Steel: Stainless Steel is anti-corrosive and due to its mechanical properties, provides higher strength and can withstand the harsh conditions in an environment.

Galvanized Steel: Galvanization is a process in which the metal is galvanized with a zinc layer that helps in prevention against corrosion.

Load-Bearing Capacity

This factor can be determined by estimating the maximum load the bracket needs to sustain. It can vary based on the application being used and this is the first step in determining the material, dimension and shape of the bracket.

Dimensions and Shape

After checking the load bearing capacity, the design and shape needs to be looked into to ensure that the application is met for the designed bracket. This includes taking certain steps such as topology optimization as well.

Mounting Options

After the dimensions are finalized, the next step will be to determine the mounting options to securely as per the application at hand. These mounting options are determined from the results of the load bearing capacity calculations.

Fabrication Techniques

There are many techniques by which sheet metal brackets are manufactured. Some major considerations that need to be kept in mind are relevant to the application of the component. Some of the most common techniques used for fabrication are listed below:

Cutting

This process utilizes machine tools, water jets or laser cutting. These methods are utilized to get a better profile and a smoother finish.

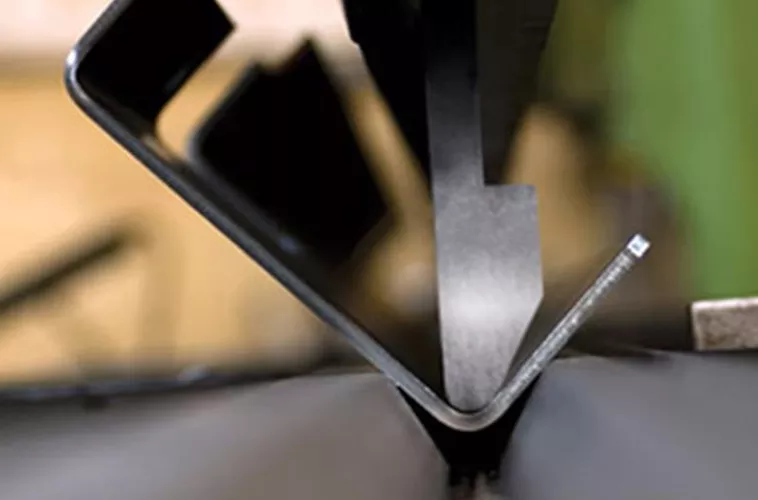

Bending

Bending the sheets at a desired angle can often be all the bracket needs.

Welding

Sometimes, the sheets are to be welded together at a certain angle for complex geometries.

Punching / Nibbling

This process is mainly used where mounts are to be made on the brackets and small notches can be made.

Finishing Options

After the fabrication stage, you would need a fine finish of the manufactured bracket and for that purpose multiple techniques are used. Some of those techniques are listed below:

Powder Coating: This process involves dry deposition of a carbide layer onto the metal surface that provides a good quality finish.

Painting: For corrosion prevention, painting is the most common method of finishing being used.

Anodizing: This process is relatively complex but very effective for corrosion prevention of aluminum brackets to avoid decolorization of the surface.

Plating: In this method, you can deposit another metal either zinc or chrome onto the bracket surface for better finish and corrosion prevention.

Possible Issues

There are multiple issues that you might encounter when developing customized sheet metal brackets. Some of these issues are listed below:

Tooling Wear: The tool wear can be due to fatigue stresses or due to constant usage. This can cause a deformation in the finalized product.

Springback: This is a phenomenon in which the material goes back to its original state and it can alter the area upon which the forces are to be exerted.

Thinning: This occurs when excessive bending or forming is done on the sheet metal that would in turn result in lesser structural strength.

Cost: At times, cost is a constraint too and it can be a blocker for you in sheet metal brackets fabrication especially in the finishing stage as anodizing and plating can be costly.

Conclusion

Custom manufacturers around the world use various technologies to form variations of shapes for metal brackets. It is a simple process but it has its fair share of bottlenecks that need to be kept in mind. Ductility of the material is quite crucial in the fabrication process to avoid permanent damage to the bracket. Embracing the latest technologies in manufacturing is important for technological advancements that could eventually lead to novelty in design.