Introduction: The Role of CNC Machining in Healthcare

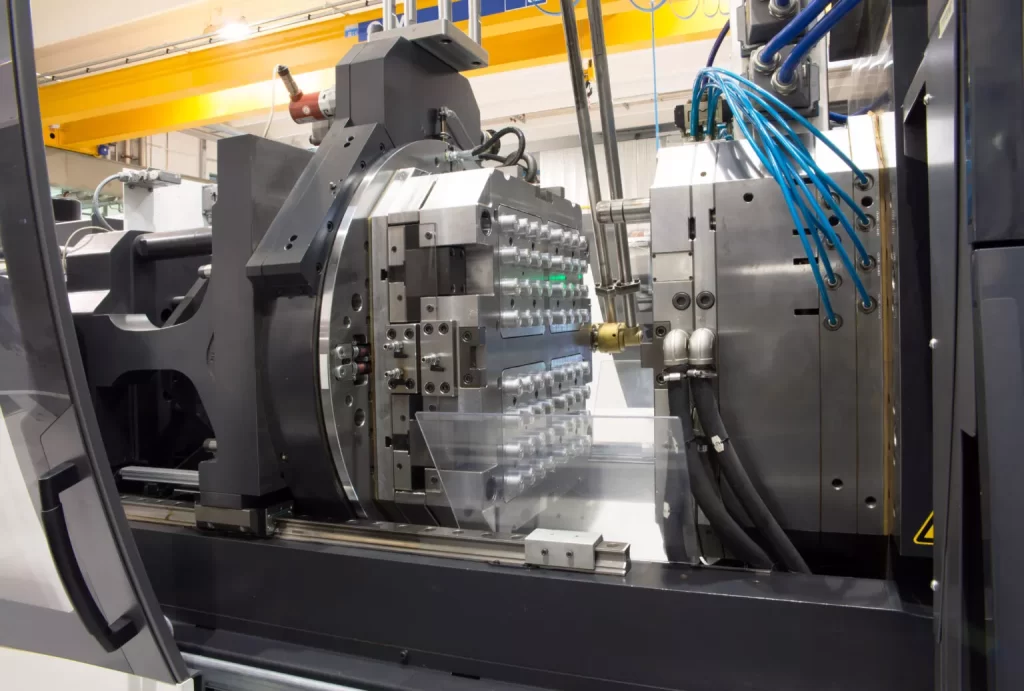

Overview of CNC Machining in Mold Manufacturing for Healthcare Applications

In the dynamic landscape of healthcare, precision and innovation are paramount. One of the key technologies driving this progress is Computer Numerical Control (CNC) machining. Within the realm of medical manufacturing, CNC machining plays a pivotal role in the fabrication of molds critical for the production of various healthcare devices and components.

CNC machining delivers unmatched accuracy and intricacy, enabling the creation of highly detailed molds for medical applications. From surgical instruments to implantable devices, CNC machining ensures each component meets stringent healthcare standards.

Moreover, CNC machining allows for rapid prototyping and iterative design, accelerating the development process and facilitating innovation in healthcare technology.

In essence, CNC machining serves as the backbone of modern healthcare production, driving advancements that improve patient outcomes and revolutionize medical care.

Advantages of CNC Machining for Healthcare Production

Precision Engineering: Enhancing Accuracy in Medical Device Manufacturing

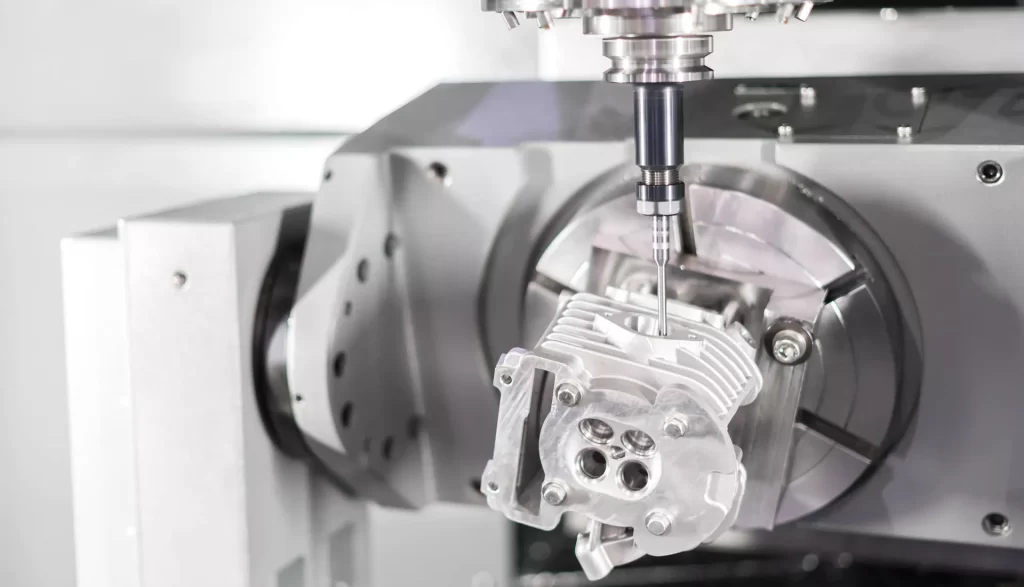

In the realm of healthcare production, precision is paramount. CNC machining offers unparalleled precision engineering capabilities, ensuring the accuracy and quality of medical device manufacturing. With CNC machining, intricate components can be produced with micro-level precision, meeting the stringent requirements of the healthcare industry.

CNC machining ensures precise geometries and intricate features crucial for optimal device performance in medical applications. Complete control over the machining process ensures consistent, error-free results. Additionally, CNC machining facilitates the production of complex shapes and configurations, enabling customization to meet diverse healthcare needs.

In essence, precision engineering through CNC machining not only enhances the accuracy of medical device manufacturing but also drives innovation in healthcare technology. By leveraging the advantages of CNC machining, manufacturers can deliver high-quality medical devices that improve patient outcomes and advance the standards of care.

Efficiency and Speed: Rapid Prototyping and Iterative Design

In the fast-paced world of healthcare, time is often of the essence. CNC machining offers significant advantages in terms of efficiency and speed, particularly in the areas of rapid prototyping and iterative design.

Traditionally, developing new medical devices involved lengthy lead times and manual labor. However, CNC machining automates prototype production from digital designs, reducing time and cost. It enables quick responses to design changes by programming new instructions on the fly, minimizing downtime.

Moreover, CNC machining offers high throughput, allowing simultaneous production of multiple prototypes, speeding up development. Leveraging CNC machining for rapid prototyping and iterative design accelerates product launch, responds to market demands, and enhances patient care through innovation.

Quality Assurance and Regulatory Compliance

Ensuring Consistency and Reliability in Healthcare Products

In the healthcare industry, consistency and reliability are non-negotiable. CNC machining plays a critical role in achieving these standards by ensuring that medical device components are produced with precision and accuracy, meeting the stringent requirements of quality assurance and regulatory compliance.

CNC machining ensures consistent quality by allowing the same design specifications to be reproduced with minimal variation once a machining program is set up. This repeatability is vital for meeting the exacting standards of quality required for medical applications. Additionally, CNC machining maintains tight tolerances across all parts.

CNC machining enables meticulous documentation of the machining process, including tool paths and material specifications, to demonstrate compliance with regulatory standards. This documentation is essential for ensuring the safety and efficacy of medical devices.

Overall, CNC machining plays a vital role in ensuring consistency and reliability in healthcare products, ultimately contributing to improved patient outcomes and the advancement of healthcare standards.

Meeting Regulatory Standards in the Healthcare Industry

In the healthcare sector, adherence to regulatory standards is paramount to ensure the safety and efficacy of medical devices. CNC machining plays a crucial role in meeting these rigorous standards by providing manufacturers with the means to produce components that comply with regulatory requirements.

Regulatory bodies like the FDA enforce strict guidelines for medical device design, manufacturing, and distribution to ensure patient safety. CNC machining helps manufacturers comply by maintaining precise control over the production process. By programming machining instructions directly from digital designs, CNC machines replicate intricate geometries with minimal variation, meeting regulatory standards.

By leveraging CNC machining for quality assurance and regulatory compliance, manufacturers can ensure that their products meet the highest standards of safety and efficacy.

Collaboration for Innovation

Partnering for Progress: Collaboration between Experts and Healthcare Professionals

Innovation in healthcare thrives on collaboration between experts in various fields and healthcare professionals who understand the real-world needs of patients. CNC machining plays a pivotal role in facilitating this collaboration by providing the tools and technology necessary to bring innovative ideas to life.

Partnering with CNC machining experts allows healthcare professionals to utilize their design and manufacturing expertise in developing advanced medical devices. These experts possess extensive knowledge in translating design concepts into functional prototypes and production-ready parts.

Collaboration between CNC machining experts and healthcare professionals fosters a deeper understanding of the unique challenges in medical device development. By working closely together, they can identify opportunities for innovation and improvement, leading to more effective healthcare solutions.

Collaboration also enables the utilization of advanced technologies and techniques in healthcare. CNC machining facilitates the production of complex geometries and intricate features, impossible with traditional methods, opening doors for innovation.

Ultimately, collaboration between experts and healthcare professionals is essential for driving progress in healthcare technology. By partnering for progress and leveraging the capabilities of CNC machining, we can continue to push the boundaries of innovation and improve patient care.

Trends and Sustainability

Sustainable Practices and Emerging Technologies in CNC Machining for Healthcare

As the healthcare industry evolves, there is a growing emphasis on sustainability and environmentally responsible practices. This trend extends to the realm of CNC machining, where manufacturers are increasingly adopting sustainable practices and integrating emerging technologies to minimize their environmental impact.

In CNC machining for healthcare, a key trend is the adoption of sustainable materials and processes. Manufacturers are exploring eco-friendly alternatives to traditional plastics, ensuring comparable performance with lower environmental impact. Advancements like high-speed machining and minimal lubrication techniques reduce energy consumption and waste generation, promoting sustainability.

Another trend is integrating renewable energy sources into CNC machining operations, such as solar and wind power. This reduces reliance on fossil fuels and lowers carbon footprints.

Emerging technologies like additive manufacturing (3D printing) revolutionize medical device production by minimizing material waste. Advances in CAD and simulation software optimize machining processes for efficiency and sustainability.

By embracing sustainable practices and emerging technologies, CNC machining can drive sustainability in healthcare. Manufacturers prioritizing sustainability not only reduce environmental impact but also enhance competitiveness and contribute to the planet’s long-term health.

Conclusion: Choose Precision for Your Healthcare Solutions

Experience Precision Mold Manufacturing with Our Advanced CNC Machines and Expertise.

At rjcmold.com, we specialize in precision mold manufacturing for healthcare. With deep expertise in medical applications, we use state-of-the-art CNC machines to ensure top-quality components.

Our commitment to precision is evident throughout our operations. From design to production, we employ advanced CNC techniques to meet exact specifications. Our strict quality control guarantees accuracy and consistency.

What sets us apart is our skilled team, bringing years of experience to every project. With a history of innovative solutions in healthcare, we collaborate closely with clients to exceed expectations.

Choose rapidmanufacture.com for precision, quality, and reliability in healthcare manufacturing. Contact us today to learn more.