Introduction:

Classic ship restoration is unique in terms of conserving nautical history and appreciating bygone periods of craftsmanship. However, one typical issue encountered during restoration efforts is the lack of discontinued components required to preserve the authenticity and structural integrity of these boats. In this article, we will look at how bespoke CNC machining has transformed the restoration process, allowing the reproduction of delicate and historically essential components for classic ships that have long been out of production.

The Significance of Classic Ship Restoration

Classic ships are emblems of maritime history, representing the traditions, technology, and tales of seafaring societies. From magnificent tall ships to graceful steamboats, these vessels serve as a physical connection to our maritime history, eliciting nostalgia and respect for previous generations’ creativity and mechanical ability.

Challenges of Restoring Discontinued Ship Parts

Classic ships age and need upkeep and repairs to maintain their authenticity and seaworthiness. However, obtaining new parts for these vessels, particularly those that are no longer in production, is a substantial difficulty. Discontinued components may cause restoration operations to slow, jeopardize historical authenticity, and impede classic ship operating capabilities.

Custom CNC Machining: A Solution for Discontinued Ship Parts

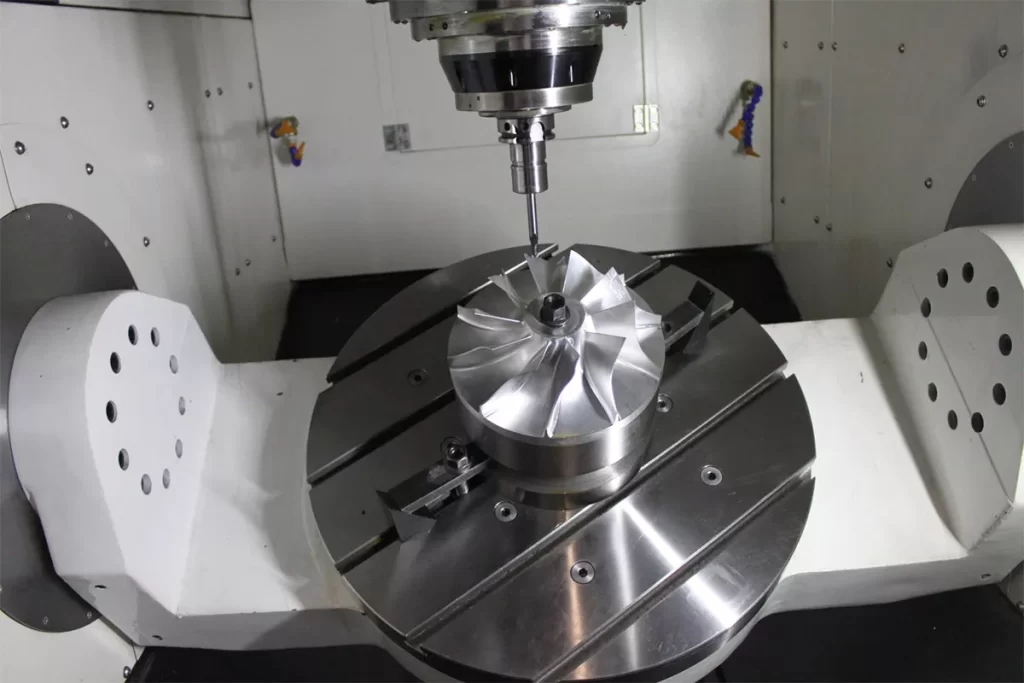

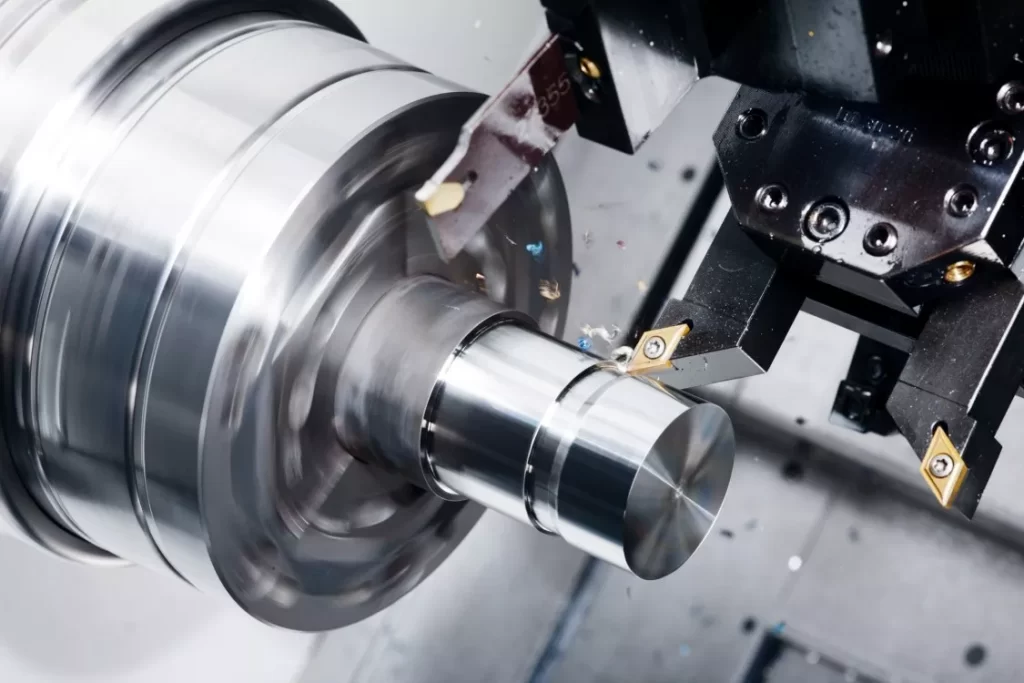

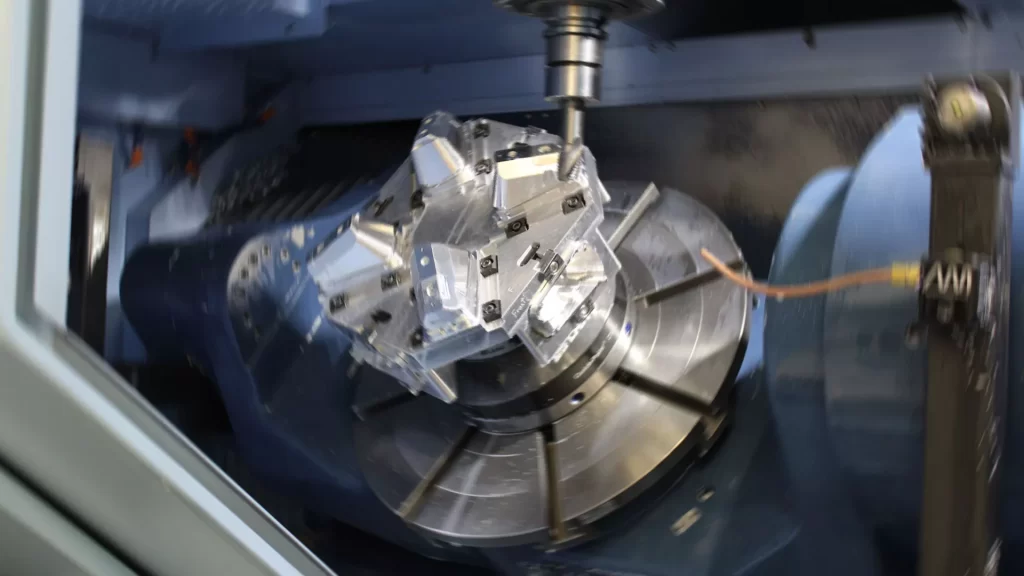

Custom CNC machining has emerged as a game changer in the realm of historic ship restoration, providing a feasible method for reproducing customized and difficult-to-find components with precision and accuracy. CNC machining technology’s flexibility and agility allow craftsmen, engineers, and shipwrights to duplicate complicated components, ranging from elegant brass fittings to specific engine parts, that are no longer commercially accessible.

Benefits of Custom CNC Machining for Classic Ship Restoration

Investing in custom-machined components provides various long-term advantages for ship lovers, particularly those who own vintage models. Here are several major advantages:

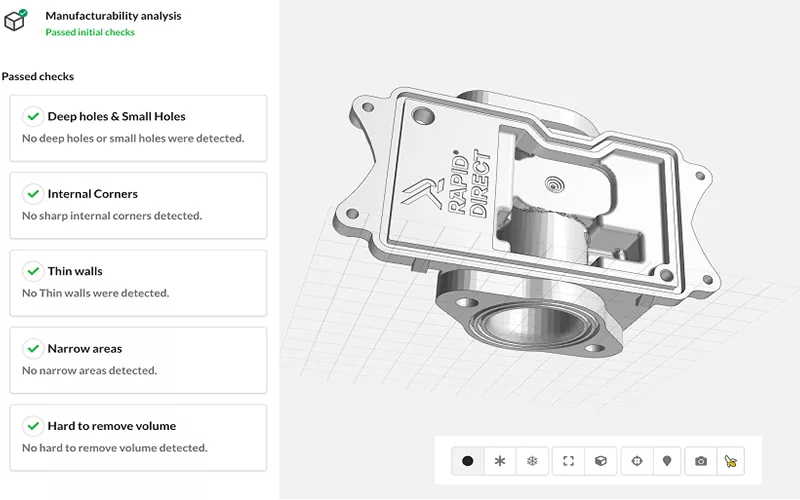

1. Precision Reproduction: Custom CNC machining enables the precise recreation of discontinued components, guaranteeing that restored ships retain their original design, functioning, and historical authenticity.

2. Material Flexibility: CNC machining works with a broad variety of materials, including metals, woods, plastics, and composites, allowing the replication of various ship components with the necessary strength, durability, and beauty.

3. Complex Geometry: CNC technology’s high accuracy and 3D machining capabilities enable the creation of complex and intricate items that would be difficult or impossible to fabricate using older techniques.

4. Cost-Effectiveness: Custom CNC machining provides cost-effective options for creating small-batch or one-of-a-kind components, removing the need for costly equipment, mold-making, and minimum order quantities that are normally associated with traditional manufacturing techniques.

5. Increased Durability: Custom components are often created from high-quality materials using precise manufacturing procedures. This means they often outlive mass-produced counterparts, making them a more sustainable option for antique ships.

6. Perfect Fit and Functionality: Because these components are custom-made to your ship’s specs, they are guaranteed to fit perfectly. This not only enhances the boat’s usefulness but also protects its integrity and worth.

7. Personalization and Aesthetic Appeal: Custom machining provides levels of customization that mass-produced components cannot match. Custom pieces may improve the entire appearance and feel of your ship, whether they complement the original aesthetics of the ship’s cabin or provide a personal touch to other areas of the ship.

8. Preservation of Ship’s legacy: For classic ship lovers, keeping the uniqueness and legacy of their ships is critical. Custom-machined pieces serve an important role in ensuring that ships continue to sail while retaining their historical integrity.

Applications of Custom CNC Machining in Classic Ship Restoration

1. Replicating Elaborate Deck Fittings: A restoration project for a ship necessitated the fabrication of exquisite brass deck fittings that are no longer being manufactured. Custom CNC machining can be employed to replicate these ornamental fittings with accuracy, intricacy, and longevity, resulting in a seamless integration into the vessel’s deck structure.

2. Manufacturing Engine Components: A classic ship undergoing repair required which requires outdated engine components can also be replaced using the CNC machining process. Custom CNC machining was used to create complicated cylinder parts, valve components, and piston rods that met the original specifications’ demanding quality and performance standards.

Future Prospects for Custom CNC Machining in Ship Restoration

The use of bespoke CNC machining in classic ship restoration is a game-changing method for conserving maritime heritage, revitalizing age-old skills, and ensuring the legacy of historic ships for future generations. As technology progresses and machining skills improve, the options for rebuilding obsolete ship components with unparalleled accuracy and efficiency become unlimited.

Conclusion

Finally, the use of specialized CNC machining to restore discontinued portions of antique ships is more than just technological innovation; it reflects a deep commitment to legacy preservation, craftsmanship resurrection, and historical stewardship. Restoration enthusiasts, maritime museums, and shipwrights may employ CNC technology to breathe new life into historic ships, guaranteeing that their heritage lives on and inspires nautical enthusiasts and history enthusiasts all over the globe.