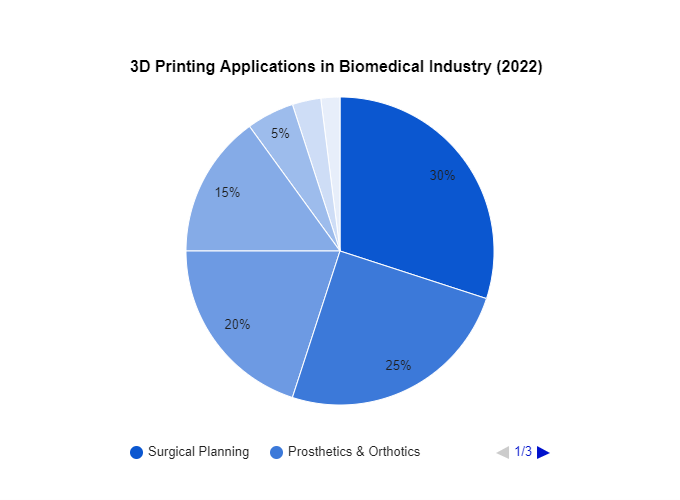

Biomedical 3D printing is the process of making three-dimensional models for healthcare applications. You can also create custom models for specific patients. Stereolithography (SLA) and fused deposition modeling (FDM) are modern printing technologies that can be incorporated into several industries. The most common examples are surgical planning, prosthetics, tissue engineering, and medical training.

Medical Modeling for Surgical Planning

3D printing for planning surgery is changing how we prepare before the operation. It gives correct models, the same size as the real, and specific to each patient.

If you look at traditional surgical planning practices, you will notice that it depends on two-dimensional imaging. This makes it pretty hard for the surgeon to study the complex anatomical structure. However, by incorporating contemporary imaging devices like CT and MRI scans, surgeons can fetch deeper insights so they can suggest more accurate procedures.

Reference: PubMed Central on 3D Printed Models in Surgical Planning

Applications in Neurosurgery and Cardiovascular Procedures

Neurosurgical Planning:

Neurosurgery is a careful and complex job where even small changes can result in big risks. With models made by 3D printing, neurosurgeons can better practice difficult surgeries. They create a prototype of patient’s brain or spine that looks exactly like the real one. With things like fixing aneurysms or removing tumors, printed models give surgeons a way to plan surgical routes. They get the chance to rehearse methods prior to the real surgery. Such a process decreases unexpected results.

Cardiovascular Modeling:

3D printing is a great resource in heart surgery because it helps surgeons make 3D models of hearts. Thus, doctors can effortlessly plan complex procedures. So, these 3D models help significantly visualize the heart anatomy. With these models, doctors can execute more reliable, swift and precise surgeries conveniently. Choosing appropriate tools and practising is much easier. Subsequently, the other benefits include faster decision-making and uncertain situations are very less.

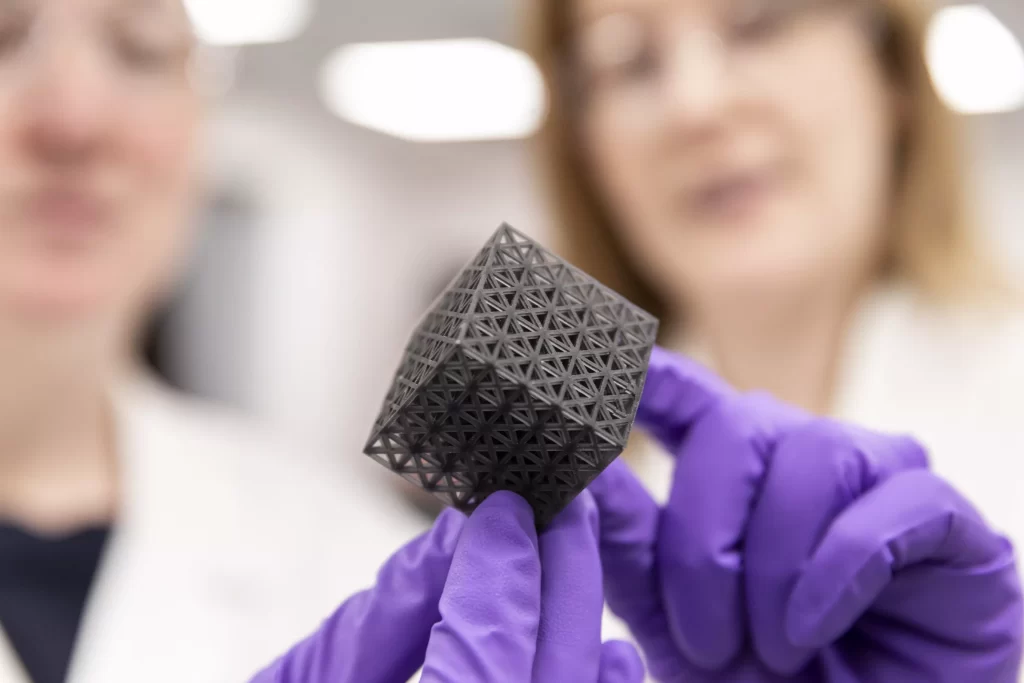

Customized Prosthetics and Implant Design

The field of prosthetics has developed drastically with 3D printing. For example, it is better than traditional prosthetics and pretty affordable, too. On the other hand, custom-printed molds can meet specific user needs and give precise measurements.

Applications in Orthopedics and Cardiovascular Implants

Orthopedic Surgery:

In orthopedics, customized implants are very popular. For example, surgeons incorporate them for joint replacements and spinal corrections. With custom-printed 3D molds, you can easily produce knee implants tailored to patients’ anatomy. So, the rejection rate of mold making is very minimal.

Dental and Cardiovascular Implants:

Subsequently, 3D printing is capable of creating high-precision implants for dental surgery. These implants are made following exact surgical guidelines. Cardiovascular implants are another example, and they include valve and stent replacements. So these parts can also be personalized following every patient cardivascular structure. With this the risk of complications are very little.

Customization is quite important in prosthetics for implant alignment. The mold should follow the patient’s physical structure; comfort is equally important. Similarly, 3D printing in biomedical molding reduces costs significantly.

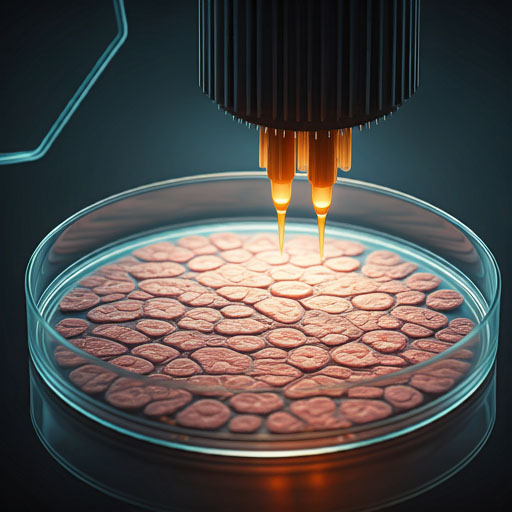

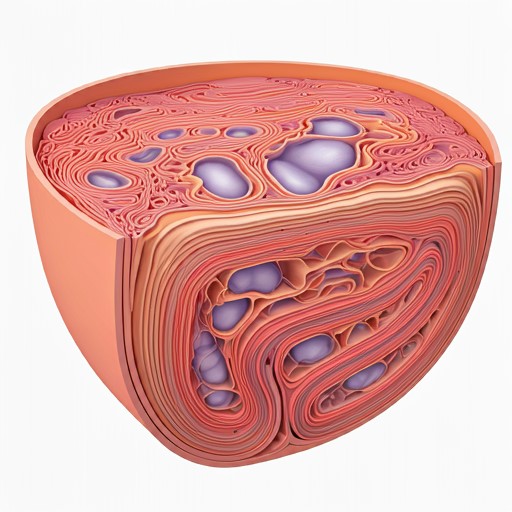

Tissue Engineering and Bioprinting

Bioprinting is one of the most advanced applications in the 3D printing biomedical field. In this method, molding companies use biocompatible materials like bio-inks combined with living cells to create a prototype of tissue that resembles real human tissues.

Let’s take the regenerative medicine field as an example. This field is a dominating beneficiary of bioprinting. For instance, it is used to create artificial tissues for:

- Skin grafts

- Cartilage regeneration,

- And organ transplantation.

3D Medical Molds Applications in Regenerative Medicine

Skin and Cartilage Regeneration:

Bioprinting has enabled the generation of artificial skin grafts for burn victims. Artificial skin-like textures made from bioinks and biocells have been developed for stoma and scar reduction. Similarly, cartilage bioprinting assists in the repair of damaged cartilage in the joints, which is important for the treatment of arthritis diseases.

Organ Printing:

When searching for the application of 3D printing technology, researchers have begun to attempt to print some complex organs, such as kidneys, livers, and hearts. At present, these organs are used in research; however, the ultimate aim is to develop such social organs that can be transplanted. This method may outclass the organ shortage difficulties and provide a rich organ bank for needy people.

In this field, bioprinting will soon reduce the need for organ donors. Hence, it will help to fill the critical gap of organ shortage in critical operations.

Reference: Nature Biotechnology on Tissue and Organ BioprintingAnatomical Modeling for Medical Simulation and Training

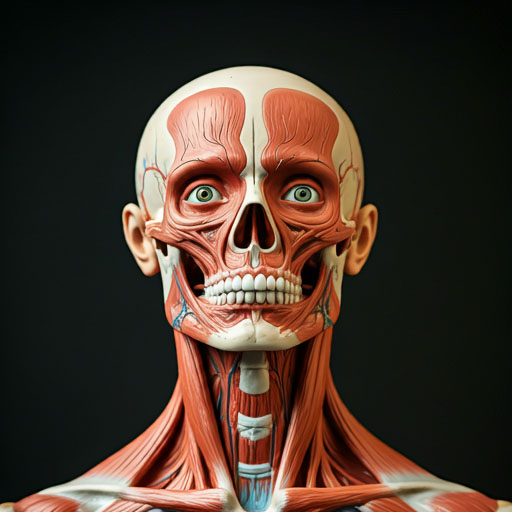

3D-printed anatomical models are overwhelmingly being used for educational purposes. In which way these molds are beneficial? For example, medical teachers can incorporate and replicate specific anatomical features. So the doctors can practice easily in a very controlled environment. Physical models are a great source for learning theoretical things in the real world.

Applications in Medical Simulation

Surgical Training:

The trainee surgeons find it extremely difficult to apply theoretical knowledge in the practical field. To assist them, 3D printed models are a great source to apply real-time learning on physical models. Be it bone fracture, or complex organ structure, trainees can be familiar with real-world scenarios.

Medical Student Education:

In the same scenario, 3D-printed models provide a more realistic and tangible learning experience for medical students. It is far better than virtual or 2D simulation. In particular, anatomy models help students understand the concepts of spatial connection and complicated body parts’ features.

So what are the benefits? Students can accelerate their practical learning and get immersive knowledge. Applications in Cancer Research and Cardiovascular Modeling

Biomedical 3D printing is also massively changing cancer research. For instance, medical researchers tend to order 3D printed models of tumors so they can study tumor structure and how they can control it. Subsequently, doctors can plan for targeted cancer therapies for tailored treatments.

Cancer Research Applications

Now this is a very interesting part. Researchers face significant difficulty in treating tumors due to their varied structure. Similarly, it was pretty difficult to assess the impact of different medicines. However, now wth the 3D medical molds, they have physical tumor models to test and observe cancer cells. This is a personalized approach that reduces animal testing gradually to test medicines.

Cardiovascular Modeling

3D printed cardiovascular models are proving very valuable to treat complex heart conditions. For example, doctors examine patients’ heart 3D replicas and analyze the actual issues. Similarly, recommending medicines also becomes very easy.

This is very helpful in congenital heart defect repairs. You can say that it is a great way to test drug responses in particular conditions. These models also assist cardiologists in planning effective interventions.

Summary

Biomedical 3D printing is somehow facing regulatory approval challenges in some countries such as bioprinting human tissues. However, this field is evolving continuously. The advantges are numerous. In short, 3D medical molds are paving new ways for personalized precision treatment and medication.

Order Your Next Biomedical 3D Printed Models with rapid manufacture

rapid manufacture is a top-rated medical injection molding supplier providing molding services for large and small scale medical molds. Our company also offers die casting molding, two shot molding, and In-mold decoration for more realistic prototypes.