Sheet Metal Fabrication

Rapid Manufacture is up to the task whether your company needs mass-produced sheet metal fabrication parts or one-off sheet metal fabrication parts.

Custom Sheet Metal Fabrication Services - Rapid Manufacture

Founded in 2002, Rapid Manufacture has served many industries requiring world-class metalworking, including fabrication, metal forming, stamping, welding, and more. Our high-quality metal fabrication and engineering services provide industries with the tools and resources to stand out in their respective fields. Our extensive experience allows us to complete any metal fabrication project. We provide high-value custom sheet metal components to a wide range of industries. Examples include transportation, waste management, military and government, mining, food service and sanitation, mechanical, architectural and construction, institutional/recreational, pharmaceutical, general industry, agriculture, startup startups, and more.

Rapid Manufacture’s state-of-the-art 10,000+ square meter facility provides innovative solutions, profitable results, and a high level of performance and quality that exceeds expectations for customers worldwide.

Get an Online Sheet Metal Quote

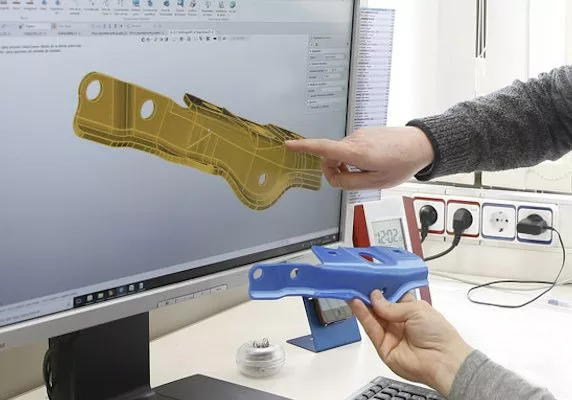

Rapid Manufacture’s online sheet metal fabrication service simply requires uploading a 3D CAD file to request an online quote for your sheet metal design. Within a few hours, we will send you pricing and can discuss the manufacturing design with you. Rapid Manufacture offers a range of sheet metal materials, including aluminum, copper, steel and stainless steel, as well as assembly services such as installation of PEM inserts, welding and finishing services. With its own domestic and overseas manufacturing facilities, Rapid Manufacture offers competitive custom sheet metal fabrication prices for low-volume prototypes and cost savings for high-volume production.

- Lead time from 5 days

- From 1 to 10,000+ parts

- Wide range of processes available

- ISO and IATF certified

What Is Sheet Metal Fabrication?

Sheet metal fabrication is a subtractive manufacturing process that forms parts from thin metal sheets. Engineers often choose sheet metal parts for their high precision and durability, especially for end-use applications like chassis, enclosures, and brackets.

Rapid Manufacture’s online sheet metal fabrication services provide a fast and cost-effective solution for any parts that need to be made from 3D CAD files or engineering drawings. Rapid Manufacture offers a range of sheet metal materials, including aluminum, copper, steel, and stainless steel, as well as assembly services like installing PEM inserts, welding, and finishing services. With a network of domestic and overseas fabricators, Rapid Manufacture can supply any quantity of sheet metal parts from low-volume, high-mix prototypes to high-volume production runs. Rapid Manufacture offers competitive, custom sheet metal fabricating prices for low volume prototypes and cost savings for high volume production runs.

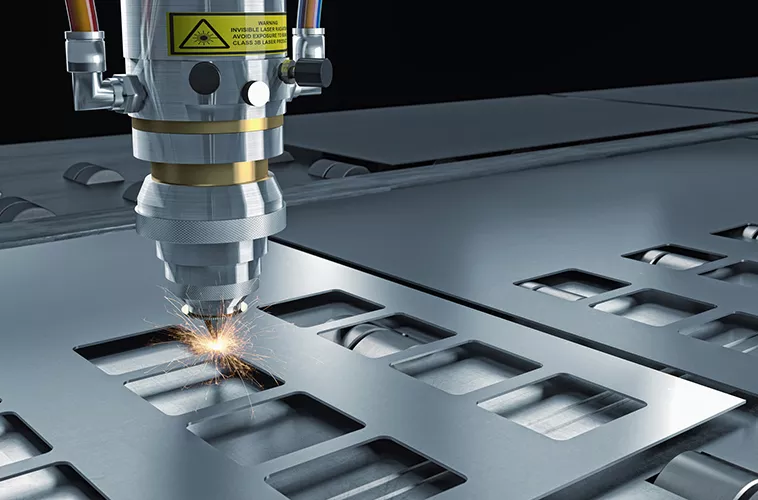

Laser Cutting

Laser cutting is a technology that directs a high-power laser to cut sheet metals, offering precision, fast processing, and the ability to create intricate designs with smooth finishes and tight tolerances.

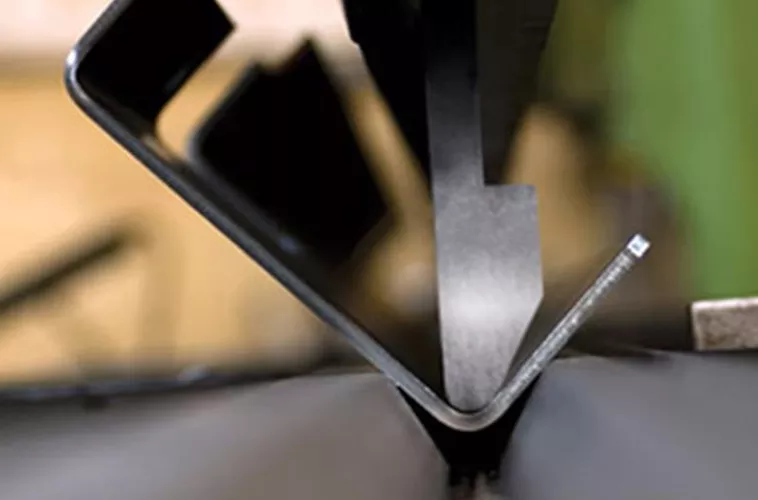

Sheet Metal Bending

Bending is a versatile sheet metal fabrication process that creates V-shape, U-shape, and channel shapes in materials, providing high precision and repeatability with minimal setup cost. Perfect for complex geometries.

Stamping

Sheet metal stamping services include various sheet metal forming manufacturing processes such as punching, stamping, blanking, embossing, bending, flanging and embossing. The metal strip is produced into the desired shape or part.

Plasma Cutting

Plasma cutting is a process that cuts through electrically conductive materials using an accelerated jet of hot plasma. Ideal for thick materials, it offers high speed, low cost, and efficiency for large-scale industrial metal fabrication.

Sheet Metal Prototyping and Production Services

We can help you fabricate your enclosures, brackets, assemblies, weldments, enclosures, housings, and other sheet metal parts and prototypes quickly and accurately. Our rapid sheet metal prototyping and production services include various tools, hand-manufacturing techniques, and processes that allow us to realize some highly complex parts.

How Rapid Manufacture Sheet Metal Fabrication Works

Rapid Manufacture’s custom sheet metal fabrication services utilize the top sheet metal fabricators in the US and globally. Sheet metal fabricators first convert CAD and drawing data into machine code. A laser cutting, waterjet, or plasma cutting machine will then precisely remove sheet metal material. The raw material is formed into angular bends and features using brakes, punches, and dies. If any assembly or post-processing is required, our sheet metal manufacturers will weld, add inserts, or finish the part.

The efficiency and high precision of sheet metal fabrication, coupled with Rapid Manufacture’s variety of materials, range of sheet metal fabricators, and post-processing options means you can get parts for any application. Sheet metal applications include aerospace, defense, automotive, energy, industrial, medical, dental, and consumer products.

Applications and Advantages of Sheet Metal Fabrication:

- Fast, Instant Online Quote

- Rapid Tooling

- Quick Prototypes

- Lead times starting at 3 days

- No minimum order quantities

- Volume-based discounts

FREE INSTANT QUOTE

1. Upload Files (Up to 30 at a time)

2. Select Material, Color, Finish, and Quantity

3. Add to order, select shipping, expedite, & purchase

Sheet Metal Design Guidelines and Tolerances

| Minimum Bend: | 1 Times Sheet Metal Thickness |

| Minimum Hole to Edge Distance: | 2 Times Sheet Metal Thickness |

| Minimum Hole to Hole Distance: | 6 Times Sheet Metal Thickness |

| Minimum Bend Edge to Hole Distance: | 6 Times Sheet Metal Thickness |

| Minimum Feature to Countersink Distance: | 8 Times Sheet Metal Thickness |

| Minimum Countersink Depth: | 1 Times Sheet Metal Thickness |

| Relief Cuts: | 1 Times Sheet Metal Thickness |

| Cutting Feature: | ± .00787’’ (0.2 mm) |

| Bend Angle: | ± 1.0° |

| Bend to Edge: | +/- 0.010” (0.254mm) |

Common Sheet Metal Materials

| Material | Ductility | Machinability | Weldability | Corrosion Resistance | Tensile strength | Price |

|---|---|---|---|---|---|---|

| Aluminium-5052 | 7% ~ 27% | Poor | Moderate | Good | 195 ~ 290 MPa | $ |

| Aluminium-5754 | 10% ~ 15% | Moderate | Good | Good | 160 ~ 200 MPa | $ |

| Stainless Steel-304 | 45% ~ 60% | Good | Good | Moderate | 480 ~ 620 MPa | $ |

| Stainless Steel-316L | 30% ~ 50 % | Moderate | Good | Good | 480 ~ 620 MPa | $ |

| Mild Steel-1018 | 17% ~ 27% | Moderate | Good | Poor | 190 ~ 440 MPa | $ |

| Copper-110 | 15% ~ 50% | Poor | Moderate | Moderate | 220 ~ 230 MPa | $ |

Typical Sheet Metal Finishes

| Applicable Materials | Colour | Description | |

|---|---|---|---|

| Bead Blasting | All metals | Uniform matte of raw material colour | Bead blasting is used mainly for visual purposes and comes in several different grits which indicate the size of the bombarding pellets. |

| Powder Coating | All metals | Black, white | Powder coating is typically used because it has a longer lasting, tougher finish than painting. |

| Anodizing | All metals | Clear, black, grey, red, blue, gold | Anodising is used to increase surface hardness, wear resistance and durability of metals such as Aluminium. |

What is Sheet Metal Forming?

Sheet stock is procured in a flat state and cut then formed into its final state through a series of progressive steps. For a typical sheet metal project, the first step is equivalent to sheet cutting, where a shear, laser, waterjet, plasma, or punch press is used to create the internal holes and edge features of the part. This process is also known as blanking.

Once the blank is produced, the next step is to form sheet metal using various tools, but most commonly some sort of brake. A brake press can be manual or automated and uses die inserts to create a desired angular bend, forming the two-dimensional sheet into a three-dimensional object. Sheet metal forming can bend the part in multiple directions, creating simple parts such as brackets up to highly complex geometries which may require custom die tools. Once the tools are in place, making subsequent sheet parts in production is very cost-effective. This makes sheet metal fabrication and forming ideal for low to high volume production.

Rapid Sheet Metal Prototyping

We understand the needs of engineers and industrial designers. With full in-house capabilities – bending, laser cutting, welding, as well as CNC folding, tapping, countersinking, counterboring and other processes – we offer unrivalled turnaround on one-off metal prototypes.

Bespoke Production Parts

We have the experience to produce both simple and complex sheet metal parts for the automotive, aerospace, electronics and many more industries. With no Minimum Order Quantity (MOQ), we provide the flexibility and scalable capacity that your project requires.

Our Sheet Metal Fabrication for Various Applications

Whether it’s metallic auto parts or electronic device components, Rapid Manufacture’s sheet metal fabrication has helped businesses in different industries.

Automation&Robotic

Image Accordion Content Goes Here! Click edit button to change this text.