CNC machining (Computer Numerical Control machining) is a widely used technology in modern manufacturing. However, many customers lack a full understanding of the cost structure and factors influencing CNC machining, leaving them puzzled by the significant variations in quotes from different factories. Additionally, they often wonder how to reduce these costs. This article provides an in-depth look into the components of CNC machining costs, the factors that affect them, and practical strategies for cost reduction.

“CNC Machining Costs” refer to the various expenses incurred during the CNC machining process. These include the purchase and maintenance costs of equipment, expenses for tools such as cutters and fixtures, wages for operators, raw material costs, and energy consumption. These cost factors directly impact the final price of the product and the economic efficiency of the business.

Major Components of CNC Machining Costs

1. Equipment Depreciation

Equipment depreciation refers to the value loss of CNC machines over time. This is a significant part of CNC machining costs. The depreciation cost depends on the machine’s lifespan, purchase price, and usage frequency. It is typically calculated based on the machine’s price and expected service life.

For instance, a machine costing RMB 1.2 million with a 10-year service life incurs an annual depreciation of RMB 120,000. If a batch of parts takes three days to process on this machine, the depreciation cost for those three days is approximately RMB 1,000. Sometimes, multiple machines are required to complete a batch of parts, increasing the total depreciation costs. Generally, more expensive equipment leads to higher depreciation costs.

2. Material Costs

The material used for machining significantly affects costs. Different materials, such as standard alloys versus high-temperature alloys, vary greatly in price. Additionally, tools wear out during machining and require regular replacement. Harder materials and complex part structures lead to faster tool wear, increasing costs. Other consumables, such as lubricants and coolants, also contribute to costs. While these are minor for large-scale production, they can be significant for small-batch orders.

3. Labor Costs

Labor costs refer to the wages of operators and technicians and are calculated based on machining time. Labor costs are influenced by the complexity of the process, required time, and local labor rates. More complex parts typically require more skilled labor and longer processing times, thus raising costs.

4. Facility Rent and Operating Expenses

Factory rent varies widely by location, with facilities in major cities or industrial hubs incurring higher rents. Additionally, operational costs such as equipment maintenance, electricity, and water must be considered.

For example, a factory in an industrial area may have a monthly rent of RMB 50,000 and utility/maintenance costs of RMB 20,000. Producing 3,000 parts per month would result in a per-part overhead cost of (50,000 + 20,000)/3,000 = RMB 23.

Key Factors Affecting CNC Machining Costs

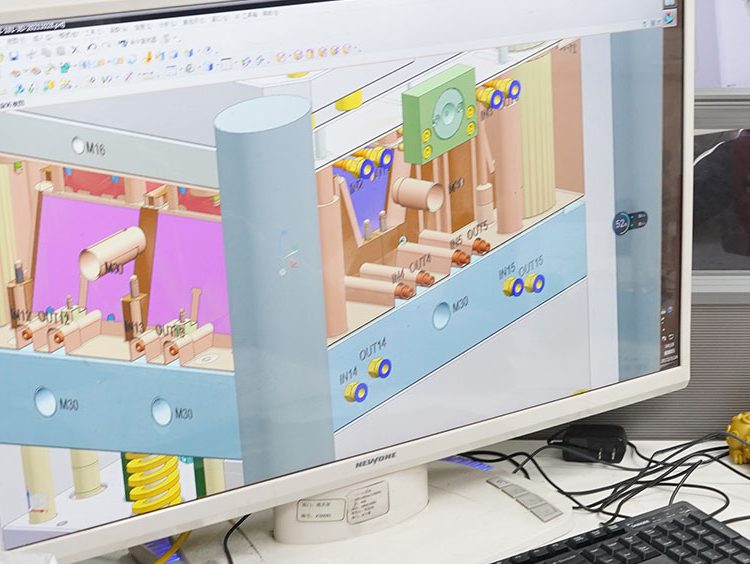

1. Part Design

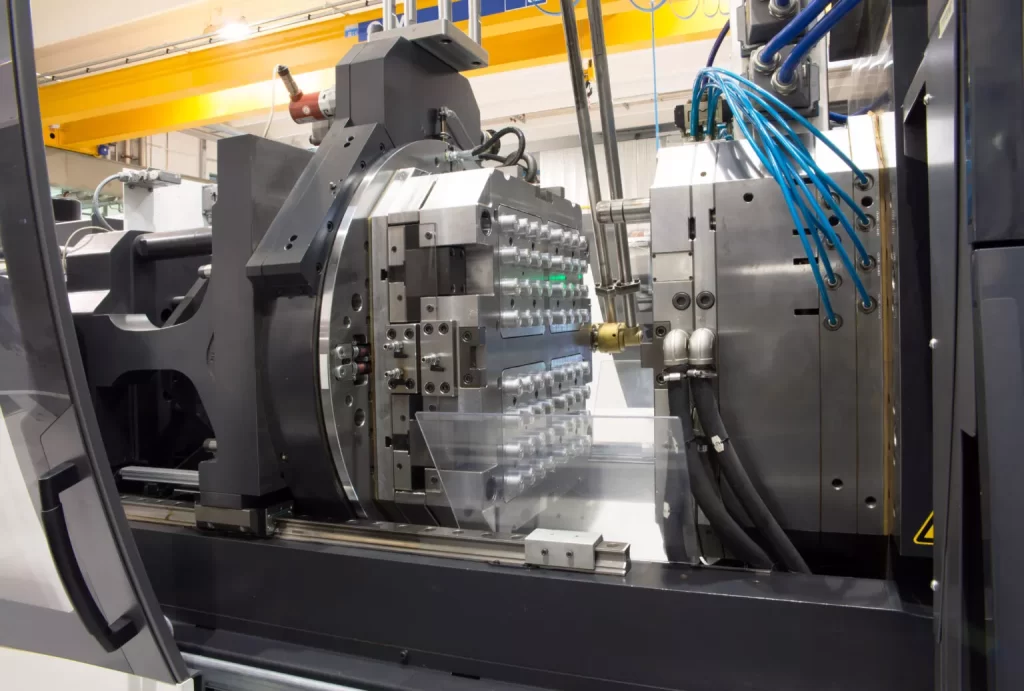

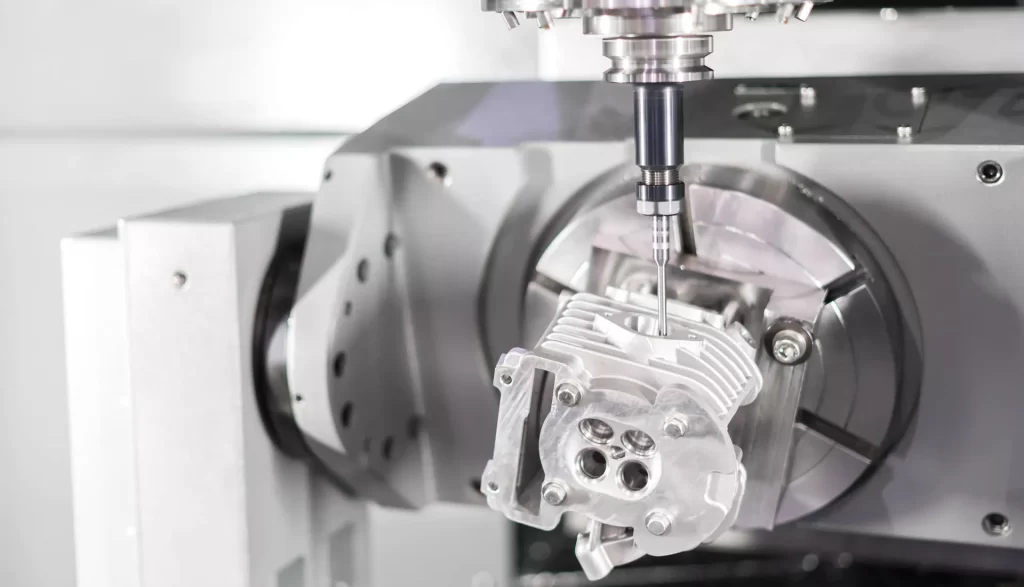

Complex designs and tight tolerances require additional machining steps, fixtures, precision equipment, and time, ultimately increasing costs. For example, while simple shapes can be processed using standard lathes and mills, intricate parts may require advanced equipment like 5-axis CNC machines. Post-processing steps such as anodizing or plating also add to costs.

2. Batch Size

Large-scale production helps amortize fixed costs, such as depreciation and setup time, reducing the per-part cost. Small-batch orders lack this advantage, resulting in higher per-unit costs.

3. Material Selection

Material properties directly influence machining difficulty. For instance, high-hardness or high-temperature alloys require specialized tools and longer machining times, increasing costs.

4. Lead Time

Short lead times may require suppliers to adjust production schedules, work overtime, or use more efficient equipment, significantly increasing costs.

Practical Strategies to Reduce CNC Machining Costs

1. Optimize Part Design

Simplify designs to reduce unnecessary machining steps. For example:

- Use rounded corners instead of sharp 90° angles to minimize machining complexity and tool wear.

- Avoid deep cavities, which require more material removal and longer machining times. A shallow cavity design can reduce costs by up to 25%.

- Avoid thin-walled structures, as they are prone to vibration and deformation, requiring slow machining and resulting in higher rejection rates. Metal parts should generally have a wall thickness of at least 0.8mm, and plastic parts at least 1.5mm.

2. Select Materials Wisely

Choose materials based on actual functional requirements. Avoid overly expensive or unnecessary high-performance materials when lower-cost options are sufficient.

3. Minimize Surface Treatments

Opt for simpler surface treatments where possible. For instance, replace anodizing with sandblasting for parts where high precision is not required, saving up to 20% in costs.

4. Loosen Tolerance Requirements

Only apply tight tolerances to critical features. For non-critical areas, relaxed tolerances can reduce machining difficulty and rejection rates.

5. Leverage Batch Production

Batch production allows fixed costs, such as programming and setup time, to be distributed across a larger number of parts, reducing per-unit costs.

6. Consider Additive Manufacturing (3D Printing)

For small-batch, complex parts with low precision requirements, 3D printing can be more cost-effective than CNC machining.

7. Choose Appropriate Equipment

Match the equipment to the complexity of the part. For simple parts, standard CNC machines are sufficient and more cost-effective than advanced 5-axis machines.

8. Compare Multiple Suppliers

Some factories may have underutilized capacity and offer lower quotes to secure orders. Comparing multiple suppliers can help identify cost-effective options.

At last, hope this guide could help you better communicate with suppliers and select cost-effective machining solutions. By understanding cost structures and implementing the above strategies, you can achieve effective cost control while maintaining quality.

Rapid Manufacture, with over 20 years of experience, is here to support your projects, helping you reduce costs and produce products that meet everyone’s expectations. Contact now.