Welding and connecting techniques are vital in today’s sheet metal fabrication, as they provide the required strength and reliability in different sectors. The trusty manual welding operation and cutting-edge arc techniques are all part of welding technology. They can improve the quality of fabrication as well as the efficiency and safety of production.

For welders today, mastering welding parameters and equipment, whether through practical experience or a welding technology certificate, is the main key to success. The Welding Society of America Certification Programs enable welders to acquire skills needed to comply with industry standards, which results in more job opportunities and higher-quality products.

This article will discuss various welding process options, such as gas metal arc welding, manual welding methods, and advanced welding parameters, to assist readers in choosing the most appropriate connection methods for their projects. The learners will be up-to-date with the welding technology used to fabricate. The types of required equipment and how tank treads are changing their technology to sheet metal fabrication today.

What Is Sheet Metal Welding?

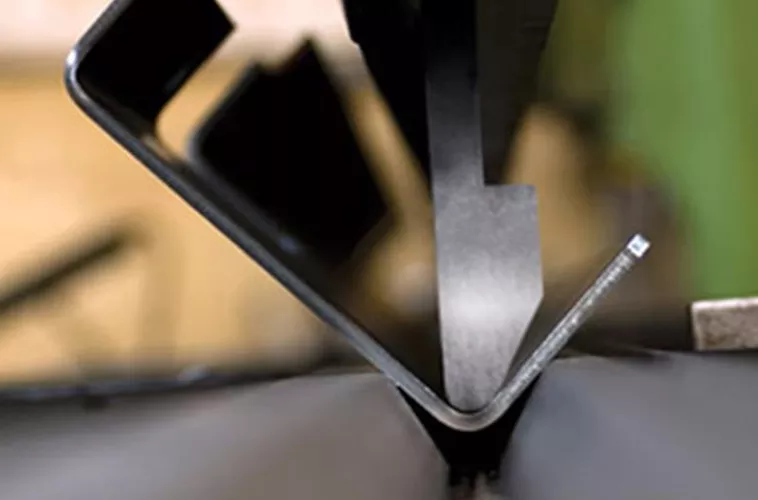

Sheet metal welding is a manufacturing method that joins thin metal sheets to form robust structures. It is an important part of the production process, producing pipelines and precision components. Qualified welders often apply GMAW and other methods to produce high-quality welding and guarantee the construction’s rigidity.

Automation in today’s manufacturing industry is revolutionizing the welding process, enabling companies to meet the stipulated requirements by ASME and increase production and efficiency. Most people who want to be welders in this field tend to take a welding program to get certified, henceforth receiving practical training under the supervision of competent trainers and foremen.

These programs embrace welding shield techniques, pipeline welding, and qualification standards, which lead to developing a workforce ready to grapple with real-life scenarios and projects. Sheet metal welding requires the right equipment, skills, and sound knowledge of welding technology; however, only recognized professionals will secure the industry’s future as it continues to grow and innovate.

Key Welding Technologies in Sheet Metal fabrication

Welding technology is vital in sheet metal fabrication for shaping pieces that meet the required quality in the automotive and heavy machinery manufacturing sectors. The unique advantages offered by different welding technologies are most noticeable in design, efficiency, and manufacturing cost.

Well-trained technicians and qualified welders are highly in demand across a plethora of labor markets, and being acquainted with the intricacies of these welding methods helps professionals wisely select the best technique for their projects. In what follows, we describe the main welding methods, emphasizing their application, capabilities, and constraints.

1. Resistance Welding

Resistance welding consists of methods like spot welding, seam welding, and projection welding, which all come in handy in fast, repetitive processes. For Volkswagen and other car companies, where welding speed is a major factor, spot welding uses an electric current to join the metal sheets.

In this process, the metal surfaces are partly melted, and the molten metal penetrates the pressed surfaces. A solid continuous seam is squeezed out on the contact point of surfaces, and welding is realized. Projection welding is a method in which the heat is concentrated at the joint area by forming projections on the workpieces.

Resistance welding is considered very productive and convenient for low-complexity parts. Still, it is not the right method for higher precision parts as the operator cannot control it to the level needed. That said, this technology often meets easier applications, which makes it a very sought-after technology as it allows to treat enormous loads of production.

2. Laser Welding

Laser welding combines speed and precision. A targeted laser beam melts and joins materials with unparalleled accuracy. The technology is suitable for thin sheet metal and complex designs, ensuring the joint connection is precise and durable. Laser technology reduces heat distortions in design processes and is typically applied to small components, like automotive and electronics industries.

However, laser welding systems are expensive, and only technicians with special certification can operate them correctly. Still, the pros of this process outweigh its minimizing of tight tolerances in manufacturing, so its implementation has become the first and only option in a quality-not-compromised production environment.

3. TIG (Tungsten Inert Gas) Welding

Gas Tungsten Arc Welding (TIG) is the best technology for its extreme welding precision and is most suited for thin sheets and “clean” applications. A tungsten electrode produces a weld with little mess and top stretch of metals in TIG welding. Thus, it’s gotten into markets where aesthetics and strength are preferred, like the aerospace and medical device industries.

While TIG welding produces the best quality finish, it is time-consuming. It requires the services of a skilled welder, preferably someone trained in the Career and Technical Education program. TIG welding still serves its purpose in scenarios where exceptional craftsmanship is necessary, even though it takes one cure of training and the welding processes.

4. MIG (Metal Inert Gas) Welding

Metal Inert Gas (MIG) welding is the go-to option for thicker sheets and offers value and accessibility over many other welding methods. MIG welding, which involves a continuous wire feed, delivers strong, resistant bonds, making it very popular in heavy equipment fabrication and the automotive sector.

Learning MIG is also a very popular option for individuals taking regular welding degree programs. Its adaptability and productivity make MIG welding an open technique, and thus, it may be suitable for those who aim to become traders or certified technicians with little training.

5. Plasma Welding

Plasma welding is a strong option to utilize along with TIG elements for intricate and delicate purposes. The plasma gas generates a soft arc through high heat and control, producing fine welds of very small diameters. Plasma welding is best for projects with high design accuracy, which requires manipulative welding techniques.

Plasma welding has a skill level akin to TIG’s quality but is typically used by certified welding specialists with advanced techniques, including arc length, electric current, and gas flow. As the world of application robotics widens, plasma welding robots are getting into those roles of performing intricate operations to ensure the smooth movement of a privacy policy and meet the demanded industry regulations.

Connection Selection in Sheet Metal Welding

Choosing the right connection method in sheet metal welding helps produce a structure with an appropriate level of stability, durability, and usability. The material type, thickness, and project requirements determine whether a connection will be permanent or detachable.

Modern welding methods such as SMAW, along with modern GTAW, can now serve the needs of shipbuilding companies, bridge construction contractors, and machinery manufacturers. The experts used devices, with the help of Industry 4.0, to increase effectiveness and adjust the connection to definite needs.

Here, we break down the key considerations in connection selection.

1. Permanent vs. Detachable Connections

The basic trouble with implementing the design is determining the type of connection that best fits the demands: the choice between permanent and detachable connections. Permanent connections, i.e., welding and riveting, are the best in cases where the durability of the connection is of great importance.

Links that can be taken apart, like bolting, make handling maintenance, upgrading, or part replacement easier. Consequently, the nature of the connection affects the project’s efficiency and service life.

● Welding: The most widely used process in manufacturing high-strength and permanent ones required in shipbuilding and bridges. Handling the materials in such processes demonstrates the effectiveness of SMAW and GTAW in various conditions.

● Riveting: A sheet metal product of a critical vibration resistance aircraft manufacturing industry is used in such applications.

● Considerations: It is also usually chosen when the charge per unit is high and long-term durability is the main concern in environments that require few maintenance works).

● Bolting: Allows the product to be easily assembled or disassembled and is ideal for machinery or products that need regular updates or repairs.

● Clamping: Applied for temporary joints in the manufacturing or construction phase, where reorganizing the components may be required.

● Considerations: Mostly appropriate for projects that may require changes in the future or when parts must be inspected or replaced frequently.

Permanent connections provide stability for high-stress applications, while detachable connections allow flexibility and maintenance, making them suitable for dynamic, evolving projects.

2. Material Compatibility and Thickness

The proper connection type, compatibility of the materials, and thickness of the sheets should be examined carefully. Even if the materials used are very similar, their qualities can be modified; for example, aluminum, steel, and different alloys interfere.

The thickness of the metal plate determines whether to weld or mechanically fasten, which, in turn, affects both the strength of the joint and the production capacity of the whole system.

Material Compatibility:

● Steel and Alloys: Steel and alloys are usually selected for the primary components of machines; thus, welding is the only way to provide long, solid joints.

● Aluminum: Aluminum is easier to work with, but we need to be careful when creating a weld because it is sensitive to changes in temperature, and the process we use is one such.

● Definite Specifications: Each material has unique requirements and limitations. Thus, SMAW is quite successful for joining heavy materials, while GTAW is a better choice for thin or delicate sheets.

Material Thickness:

● Solid Sections: Welding is the most common construction method for bridge structures, as it provides strength capable of withstanding heavy loading.

● Thin Plates: Mechanical fastening is preferred to welding because it applies less force to the surrounding material and reduces the warping risk. It is mainly used in lighter applications.

● Medium Thickness: Projects with medium/wide intermediate thickness may be best completed using either or both methods, i.e., strength and alignment, respectively.

Material specifications and a product’s thickness must be considered in selecting the most fitting connection type. Graders can thoroughly understand a material’s properties by taking welding courses. Thus, they are more likely to choose wisely during manufacturing, leading to higher product quality in sectors such as machinery and shipbuilding.

Factors to Consider When Selecting Welding Technology and Connection Methods

When selecting welding technology and connection methods in manufacturing, it is crucial to comprehend the project’s unique needs. Every option, whether gas shield arc welding or digitally connected automated methods, affects the final product’s strength, cost, speed, and appearance.

Material sensitivity and product budget are important in choosing the best path from structural strength to surface finish. Below, we have provided key issues to consider so that you can choose the right welding technology for different product and service needs.

1. Strength and Durability Requirements

The endurance of the joints in cases where power is needed, such as in the aerospace industry and iron construction, is very important. The welding technology should be designed to absorb the loads it may be exposed to over time. Gas shield arc welding is used for structural components.

Besides, it covers the weld with a gas film that prevents impurities from entering, and its strongest joint concept is learned. Therefore, it is a good fit for specific types of uses. Knowledge of these requirements and the skill to skip the technology choices to a large extent for the welder employed or the welder management are essential.

2. Production Speed and Cost Efficiency

Production speed and budget constraints are the most common drivers for selecting welding technology. Technologies that could automate the welding process can save a significant amount of time, particularly when high-volume manufacturing is needed, and the company can also save costs in doing so.

Welding programs familiarize entry-level welders with the introduction of real-time welding automation and provide them with the knowledge and skills to meet industry demands efficiently.

Techniques such as gas shield arc welding are the right choices in manufacturing processes with limited budgets. By balancing speed versus affordability, manufacturers can achieve production goals without sacrificing product quality.

3. Aesthetic and Finish Requirements

In cases where appearance is vital, the perfect finish of the weld is as important as the weld’s strength. Picking a joining process that causes little to no weld marks is vital for products that show welds and have a decorative look.

Full-length conclusions are common for products and services in customer-facing sectors, where appearance is among the key elements affecting perception. Gas shield arc welding finishes a part with a clean and polished appearance. Which is suitable for parts that are high in visibility. While methods that create a lot of spatter are more suitable for internal or structural parts.

Furthermore, the instructors in the welding certification programs that the aesthetic consideration aspects are dealt with, among other issues, and the students can thereby evaluate and use connection types to the degree that they are alternatively the best predisposed to the enhancement of the final product’s appearance.

4. Thermal Sensitivity of Materials

High-heat welding methods can affect materials that are sensitive to temperature changes. In some cases, sheet metals, especially those used in aerospace applications, require proper time treatment to be cut without thermal distortion.

Pulsed arc welding and other processes that generate low heat are among the techniques used to preserve material properties and enhance connection strength. These techniques allow students and professionals to build practical experiences through certification programs, which teach them to make the right choice of welding methods for thermal-sensitive materials.

Future Trends in Sheet Metal Welding Technology

Prospects of sheet metal welding are changing swiftly. New cutting-edge technologies assure better efficiency, accuracy, and sustainability. Some of the most impressive trends in the field are listed here.

1. Automation and Robotics

Robotic welding brings a new dimension to sheet metal fabrication, improving the process’s precision, speed, and reliability. Automation is now the technology that creates controlled, repetitive welds, influencing the human component. Better assembly of elements such as automotive components and large-scale constructions guarantees reduced material waste.

Robotics in the welding industry is reshaping the manufacturing sector. These robotic systems can now change the welding parameters using advanced sensors and machine learning technology. Which makes them useful in different industries. Automating the manufacturing process implies fewer mistakes, better quality, and a safer work environment.

2. Hybrid Welding Technologies

Hybrid welding is the best combination of different methods that provides higher quality. One of the game-changing techniques in sheet metal fabrication is laser insertion welding, which simultaneously manages the laser weld and the MIG method. In this process, the laser is the swift part, while the MIG is the flexible one.

The combination produces a weld that is both deeper and able to resist distortion, which makes it a perfect candidate for a field that requires a great degree of precision, such as auto manufacturing. The hybrid method utilizes the influence of both technologies, with time being a notable factor. But power and strength are maintained. This one is ideal for such a complex as it is very demanding.

3. Sustainability and Energy Efficiency

Sustainability is increasingly a top priority in the welding industry. Options like low-emission welding gases and eco-friendly alternative energy sources have been launched. Modern equipment that consumes less energy has been introduced, which, in turn, helps companies reduce the amount of carbon emissions they release.

Welding machines that are energy-efficient and optimized for high performance and lower environmental impact have become the norm. The shift to sustainable practices brings the planet and businesses to win, besides reducing operational costs.

Conclusion

The proper welding technology and connection method in sheet metal fabrication can improve the quality of the product, such as strength and resistance to corrosion. Manufacturers can choose the most effective method for each application if they properly consider the project requirements, material properties, and production goals.

These technologies offer specific solutions that customers need, from traditional manual welding to the most advanced hybrid techniques. Staying updated on new welding innovations will allow companies to optimize their processes.

Thus, higher efficiency and better outcomes are achieved. Adopting the most recent technological advancements in welding allows manufacturers to improve the quality of their products and increase production in a changing industry landscape.

Manufacturing is important, not just for the things it makes – but for the things it makes possible in the world. What engineers design and produce is what keeps us safe, healthy, and connected.

But here’s the truth: manufacturing can be hard. It’s filled with fragmented processes and complex supply chains. Sometimes, you just don’t have the people, technology, or resources to keep up.

Rapid Manufacture is on a mission to change manufacturing and logistics for the better. We’ve combined our Cloud Manufacturing Platform™ and our expert team to make the entire process smarter and easier. We’re making new things possible in manufacturing so you can make new things possible for the world.

Manufacturing is important, not just for the things it makes – but for the things it makes possible in the world. What engineers design and produce is what keeps us safe, healthy, and connected.

But here’s the truth: manufacturing can be hard. It’s filled with fragmented processes and complex supply chains. Sometimes, you just don’t have the people, technology, or resources to keep up.

Rapid Manufacture is on a mission to change manufacturing and logistics for the better. We’ve combined our Cloud Manufacturing Platform™ and our expert team to make the entire process smarter and easier. We’re making new things possible in manufacturing so you can make new things possible for the world.