Electrical Discharge Machining or EDM (also colloquially known as wire erosion or spark eroding) is a class of non-traditional machining processes that defies the conventional norms of sharp tools and brute strength. Instead, it relies on electric sparks to meticulously shape hard materials.

In recent times, there has been a steep rise in the usage of EDM technologies over traditional machining. If you’re a manufacturer and don’t use EDM or even know what it is, you should do so, as EDM is the future of manufacturing.

This article explores the world of EDM, explaining its core principles, various applications, and its crucial connection to Numerical Control (CNC) machining.

Understanding the EDM Process

Unlike conventional machining methods that rely on physical cutting tools and their inherent limitations, EDM offers a hyper-precise and versatile approach to shaping complex geometries in challenging materials.

In essence, EDM mimics a miniature lightning storm. A precisely shaped electrode, typically made of graphite or brass, acts as a “tool” and is strategically positioned near the workpiece. Additionally, EDM excels at creating intricate shapes with sharp corners and small details that would be difficult or impossible to achieve with traditional methods.

Here’s a breakdown of the key components:

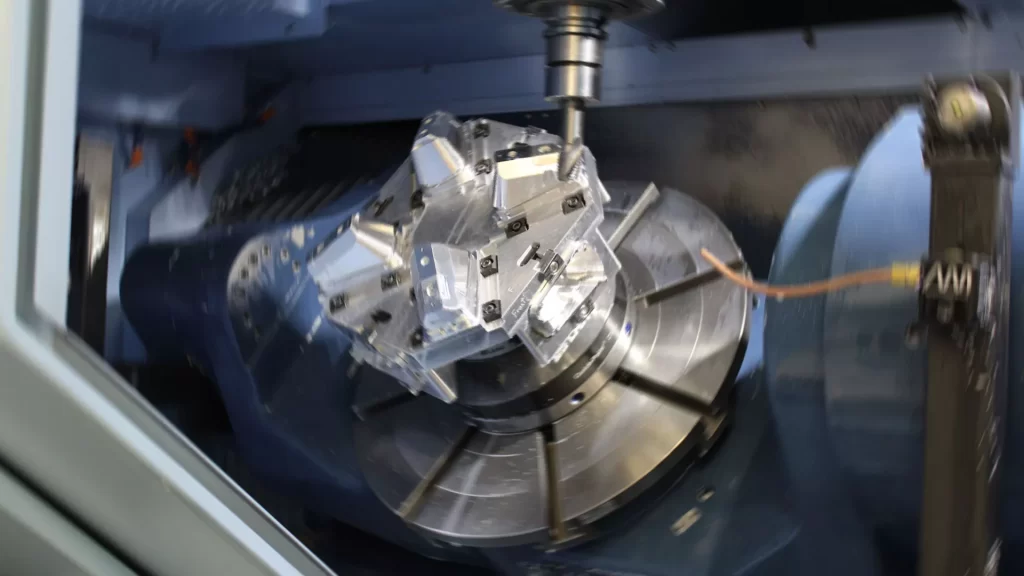

Electrode: This specially shaped tool, made from a conductive material like graphite or brass, acts as the “lightning rod” that directs the sparks.

Workpiece: This is the metal piece you want to shape. It also needs to be electrically conductive.

Dielectric Fluid: Dielectric fluid is an insulating liquid, often oil-based, that surrounds the electrode and workpiece. It helps control the spark intensity and flush away debris.

The magic happens when an electrical potential is applied between the electrode and the workpiece. This creates a strong electric field that wants to discharge like a bolt of lightning. When the gap between the electrode and workpiece gets small enough, a spark jumps through the dielectric fluid, vaporizing a tiny bit of material from both the electrode and workpiece.

This process is repeated rapidly, with the electrode continuously moved according to a pre-programmed path. As millions of these microscopic sparks occur, the material is gradually eroded from the workpiece, creating the desired shape.

Advantages of EDM: Why Use Sparks Over Cutting Tools?

So, why choose EDM over traditional machining methods? Here are some key benefits:

Machining Hard Materials: EDM excels at shaping incredibly hard metals like titanium or tool steel, which would be difficult or impossible to cut with traditional tools.

Intricate Shapes: Due to the non-contact nature of the process, EDM can achieve complex geometries and tiny features with exceptional precision.

Minimal Heat Distortion: Unlike traditional machining that generates heat, EDM removes material through localized melting and vaporization, minimizing heat distortion in the workpiece.

Fragile Materials: This technique can be used with delicate or brittle materials that might shatter under the pressure of conventional cutting tools.

Different Types of EDM

The basic principles of EDM remain the same, but there are different variations suited for specific applications:

| Type | Definition |

| Die Sinking EDM | This is the most common type, where a shaped electrode plunges into the workpiece, creating cavities and intricate shapes. |

| Wire EDM | Here, a thin wire continuously travels along a programmed path, essentially “wire-sawing” the desired shape in the workpiece. |

| Hole Drilling EDM | This technique uses a small, rotating electrode to create precise holes of various shapes and sizes. |

The Marriage of EDM and CNC

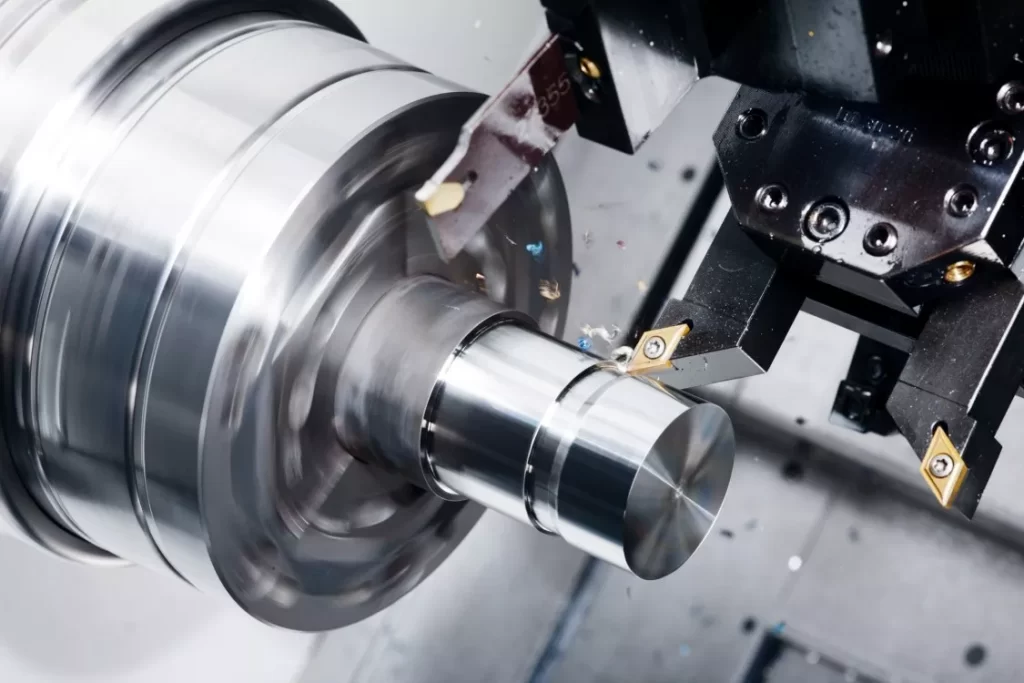

Numerical Control machining utilizes computer programs to control the movement of cutting tools. This marriage between EDM and CNC is a match made in manufacturing heaven.

CNC allows for highly precise and automated control of the electrode’s movement in EDM. This translates to:

Complex Designs: CNC programs can translate intricate designs into precise movements of the electrode, allowing for the creation of highly complex shapes in the workpiece.

Repeatability: CNC ensures consistent and repeatable results, making EDM ideal for the mass production of parts with identical features.

Efficiency: Automated control through CNC optimizes the EDM process, minimizing waste and production time.

Applications of EDM

EDM plays a vital role in various industries due to its unique capabilities. Here are some real-world examples:

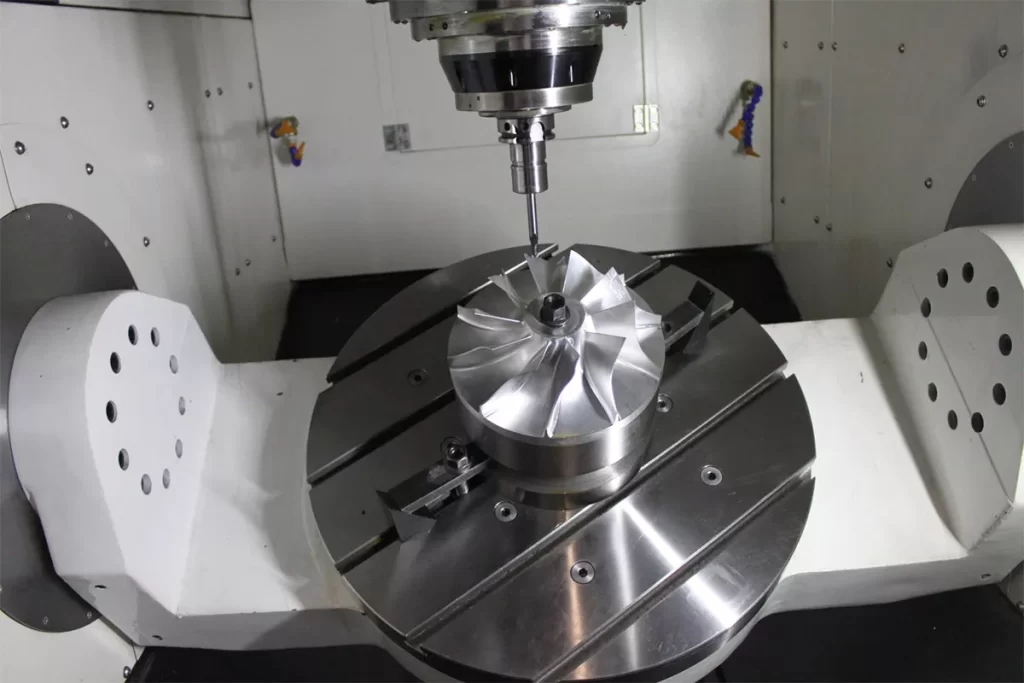

Aerospace: Manufacturing turbine blades, fuel nozzles, and landing gear components from high-strength, heat-resistant alloys.

Medical Devices: Creating intricate features in surgical tools, implants, and medical molds.

Automotive: Machining complex shapes in engine components, fuel injectors, and molds for casting parts.

Electronics: Producing tiny and precise features in electronic components like connectors and microchips.

Mold and Die Making: Creating intricate cavities and shapes in molds used for plastic injection molding and metal die casting.

The Future of EDM: Advancements and Emerging Trends

The world of EDM is constantly evolving. Here are some exciting developments on the horizon:

Advanced Electrode Materials

Research into new electrode materials is ongoing to improve cutting speeds, reduce wear, and achieve even finer finishes.

Ecological Considerations

The development of more environmentally friendly dielectric fluids is a focus, minimizing waste and disposal concerns.

Micro EDM

This technique pushes the boundaries of miniaturization, allowing for the creation of incredibly tiny features with micron-level precision.

Wire EDM Advancements

Thinner wires and high-speed wire movement are being explored to achieve even more intricate cuts and faster production times.

Hybrid Machining

Combining EDM with other machining processes, like laser cutting, opens doors for even greater versatility and complex part creation.

The Bottom Line

EDM has emerged as a game-changer for metal fabrication, offering remarkable capabilities for shaping a diverse array of materials. Unlike conventional machining methods that rely on brute force, EDM uses the power of precisely controlled electrical sparks to meticulously remove material – which ultimately translates into several groundbreaking advantages and saves you, the manufacturer, your precious time.

Looking ahead, the future of EDM is ablaze with potential. As advancements in technology and material science continue to unfold, we can expect even more sophisticated EDM processes to emerge. That will undoubtedly unlock the creation of even more intricate and high-performance components, further solidifying EDM’s position as a cornerstone of modern manufacturing.