Economies of scale are crucial for production efficiency, especially in CNC machining, where larger production volumes can offset high initial costs. Prototyping is an essential step in product development, allowing for design and functionality evaluation. CNC machining facilitates this with rapid prototyping, producing accurate prototypes for testing. However, transitioning to mass production requires careful design optimization to manage costs, as even minor design features can become expensive when produced in large quantities. For instance, design complexity in small aluminum parts, such as sharp corners, can significantly impact costs when scaled up. Features that are affordable for single units can become expensive in mass production. Therefore, optimizing design for mass production is key to achieving true economies of scale. This article aims to shed light on the key considerations when scaling up your design for mass production, particularly in the context of CNC machining.

Benefits of Prototyping in CNC Machining

The benefits of using CNC machining for prototyping include:

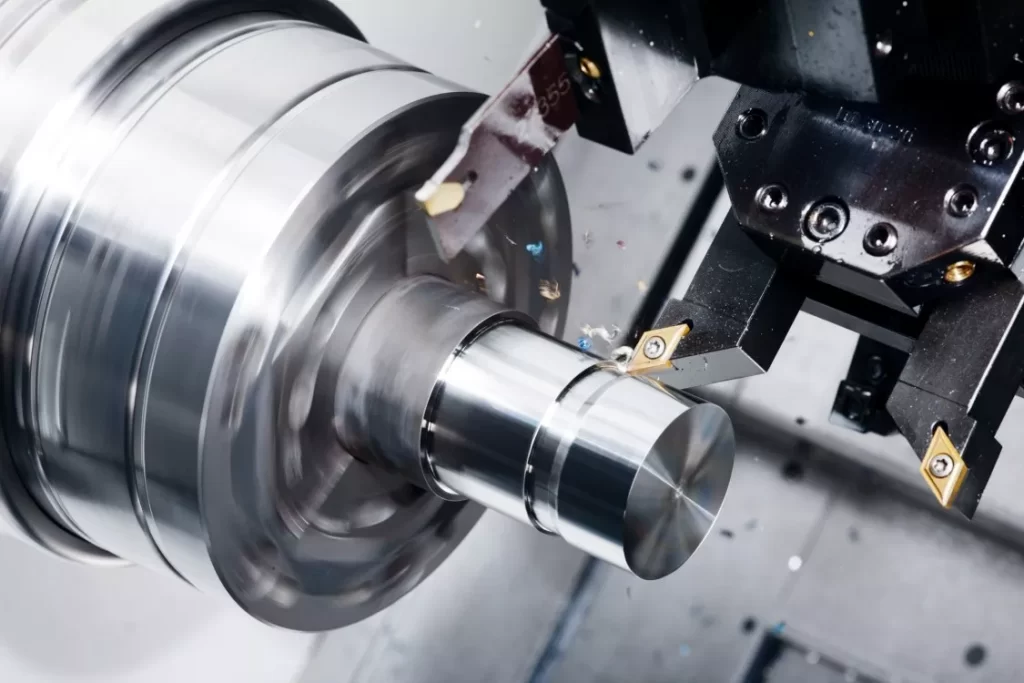

Precision and Accuracy: CNC machines can produce prototypes with tight tolerances, which is essential for industries requiring precise components.

Speed: CNC prototyping is significantly faster than traditional methods, reducing the time from concept to production.

Material Versatility: A wide range of materials can be used, allowing for functional testing with the actual materials intended for the final product.

Impact of Production Volume on Unit Costs and Efficiency

The relationship between production volume and unit costs in CNC machining is inverse; the unit cost per component typically decreases as production volume increases. This is because the fixed costs, such as machine setup and programming, are distributed over more parts, reducing the overhead attributed to each unit. Higher production volumes can also improve operational efficiencies, such as optimized machine usage and labor allocation.

Strategies for Achieving Economies of Scale

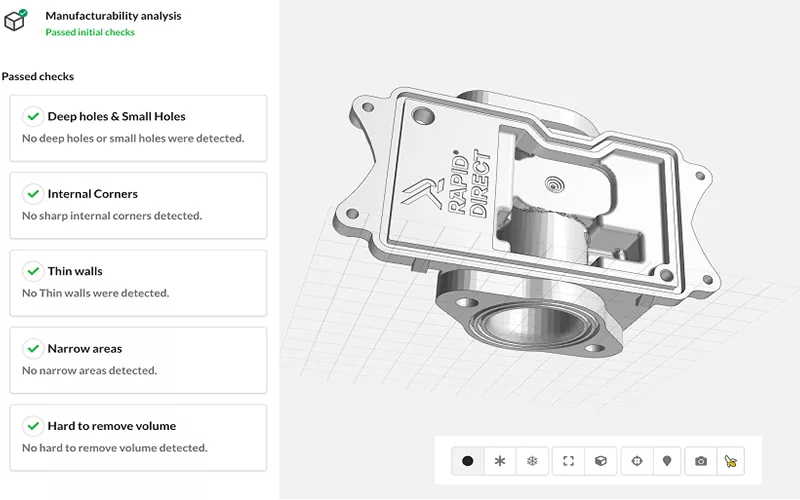

Optimizing design for CNC machining is necessary for reducing costs without compromising quality. Effective design optimization can significantly lower machining time, reduce material waste, and minimize the need for specialized tooling, all of which contribute to cost savings. To achieve economies of scale in CNC machining, manufacturers can employ several strategies:

Design with Manufacturability in Mind: Designs should be simplified to minimize machining time and reduce the need for specialized tools. This design method ensures parts fit together seamlessly, reducing the need for post-processing.

Material Selection and Standardization: Choose materials that balance cost and machinability and standardize material use to benefit from bulk purchasing. Use standard sizes, shapes, and tolerances to reduce the need for custom tooling.

Leverage Bulk Production: Plan production runs to maximize the number of parts produced simultaneously to spread the fixed costs over a larger batch.

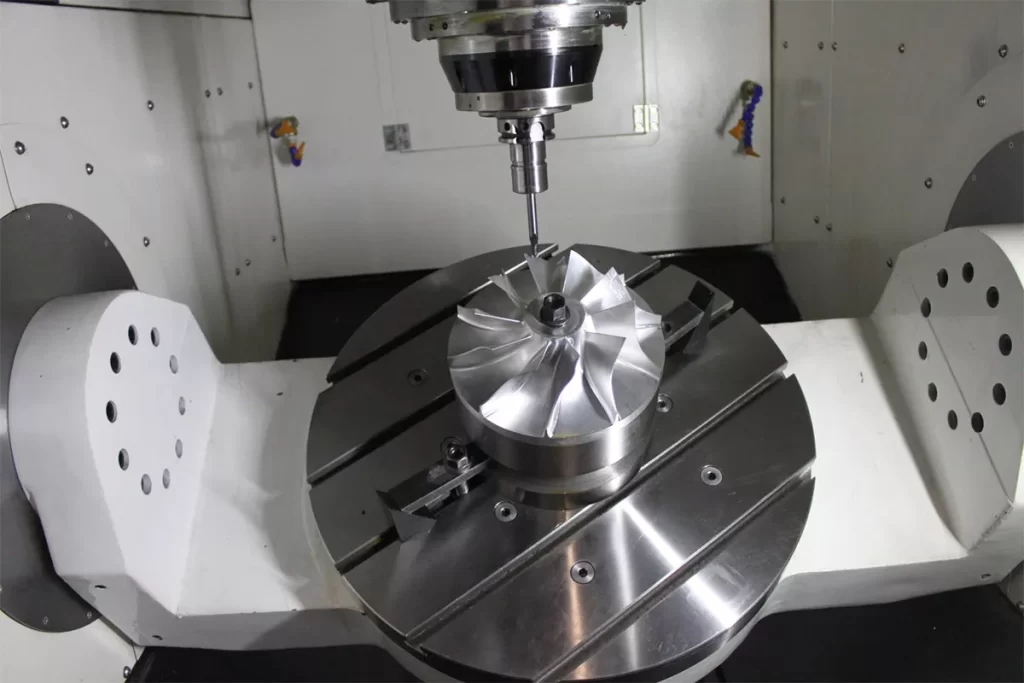

Optimize Tool Paths and Machining Processes: Use efficient tool paths and streamline the machining process to reduce cycle times. For instance, you can incorporate internal radii in vertical edges to minimize the need for multiple passes with smaller tools, which can be more time-consuming and expensive.

Automation and Robotics: Implement automation to reduce labor costs and increase production consistency.

Supplier Collaboration: Work closely with suppliers to ensure a steady supply of materials and negotiate better rates.

These strategies in CNC machining operations can significantly reduce costs and improve efficiency, allowing production to be scaled up effectively.

Balancing Design Complexity with Cost Constraints

Balancing the complexity of a design with cost constraints involves making strategic decisions about which features are essential for the prototype’s functionality and which can be simplified or removed. It’s important to prioritize the prototype’s core functions and design features that are critical to its performance while streamlining other aspects of the design to keep costs down.

By applying these design tips, manufacturers can create cost-effective CNC prototypes that accurately represent the final product while setting the stage for economies of scale in full-scale production.

Scaling Up CNC Machining Operations: Challenges and Considerations

Scaling up CNC machining operations involves several challenges and considerations that must be addressed to ensure a smooth transition from low-volume to high-volume production. These include:

Cost of Equipment and Software: The initial investment in CNC machines and software can be significant, especially for newer or smaller businesses.

Skilled Labor: There is a necessity for skilled labor to operate and program CNC machines, which can add to the costs and complexity of scaling up.

Machine Stability and Durability: For large-part machining, the stability and durability of the machine tool are crucial to ensuring the reliability of the entire machining process.

Complex Machining Requirements: Simple features may require complex machining strategies, which can increase the number of steps in the machining process.

Best Practices for Efficient High-Volume Production in CNC machining

The following best practices are recommended to achieve efficiency in high-volume production machining:

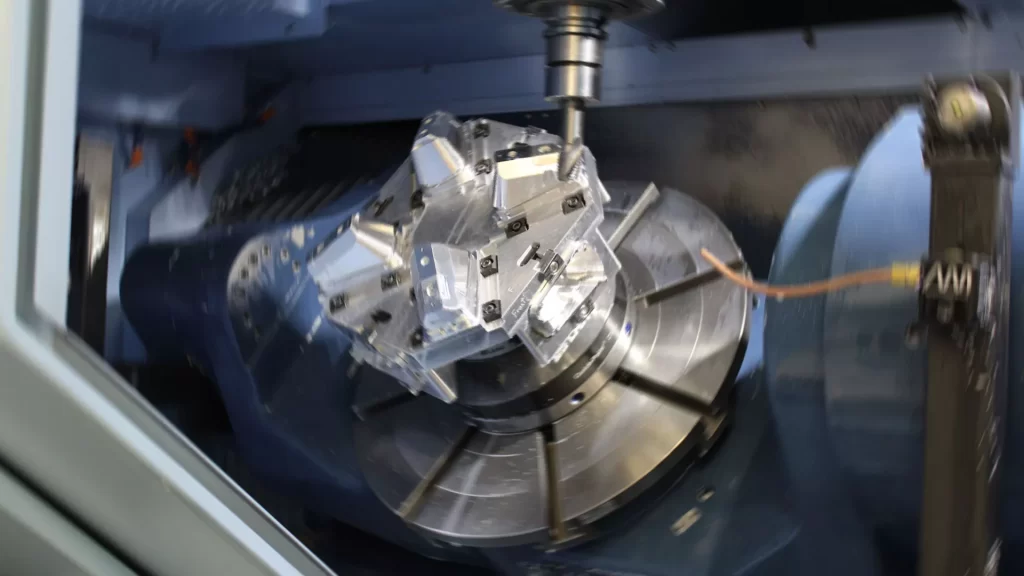

Flexible High-Production Machines: Use versatile machines that can pivot to different jobs as needed.

Automation Beyond Robots: Implement tool pre-setters, on-machine part and tool probing, and automatic tool changers to eliminate manual tasks.

Efficient Measurement/Inspection Processes: Adopt new measurement technology to speed up and simplify part measurement.

Software for Process Efficiencies: Utilize enterprise resource planning (ERP) software and data from machines for adaptive machining and statistical process analysis.

Leveraging Technology and Automation in CNC machining

The seamless integration of technology and automation is key to scaling up CNC machining. By integrating artificial intelligence into the CNC machining process, one can predict maintenance schedules and dynamically optimize cutting paths for enhanced efficiency. Also, merging machine learning with big data analytics allows for continuous refinement of processes, such as the strategic automation of tool changes, which significantly streamlines machining workflows, leading to increased productivity and cost savings. Embracing these technological advancements while adopting industry best practices empowers CNC machining to meet the rigorous demands of high-volume production while upholding quality and efficiency standards.

Looking ahead

The CNC machining industry is gaining stride, with industry trends leaning towards increased automation, the rise of smart factories, and adopting sustainable practices. The future of manufacturing will be heavily influenced by the integration of cutting-edge technologies and automation processes. Still, prototyping will continue to be an essential phase in the CNC process, laying the groundwork for production scalability. As CNC technology advances, the relevance of economies of scale will be even more emphasized, pushing manufacturers toward even higher efficiency and market competitiveness.