Introduction:

CNC machining has transformed the manufacturing business by providing precision, vasertility, and efficiency while making high-quality components. Aluminum 6061 is one of the most common materials for CNC machining due to its outstanding machinability, strength, and corrosion resistance. This guide will go over the specifics of CNC machining aluminum 6061 material components, including their qualities, applications, machining procedures, and recommended practices.

Understanding the Aluminum 6061 Material

Aluminum 6061 is a versatile and popular alloy known for its excellent mechanical qualities and weldability. It is composed of aluminum, magnesium, and silicon, making it perfect for applications that need high strength, exceptional corrosion resistance, and outstanding machinability. Aluminum 6061 is a popular material for CNC machining applications in a variety of sectors due to its excellent finishing properties.

Properties of Aluminum 6061

Strength: Aluminum 6061 has great tensile strength and toughness, making it ideal for structural applications that demand durability and dependability.

Machinability: Aluminum 6061’s exceptional machinability enables precise machining techniques such as milling, drilling, turning, and tapping with minimum tool wear.

Corrosion Resistance: Because of its corrosion resistance, the alloy is suited for outdoor applications and environments with high levels of moisture or chemical exposure.

Weldability: Aluminum 6061 is readily welded using a variety of methods, allowing for the creation of complicated structures and components.

Mechanical Properties of Aluminium 6061.

The following are the primary mechanical characteristics of Aluminium 6061.

Yield Strength

When examining mechanical qualities, one of the most important criteria is yield strength, which is the highest stress necessary to deform the item.

The maximum stress is necessary for a component to deform under stress situations like twisting, compression, and so on. The yield strength of aluminum 6061 is 276 MPa, which is equivalent to 40000 psi. Because of its great yield strength, it does not distort readily.

Thermal conductivity

The thermal conductivity of aluminum 6061 refers to its capacity to transmit heat. Its thermal conductivity is 167W/m-K, which is quite high. Its excellent thermal conductivity makes it ideal for heating and cooling applications. Its excellent heat conductivity makes it suitable for a variety of applications, including CNC machining, cooking equipment, and kitchenware.

Electrical Resistivity

Electrical resistivity is a measure of how resistant a metal or substance is to electric current. The electrical resistance of aluminum 6061 is quite low. As a result, electric current passes through it with ease. This feature makes this metal alloy suitable for a variety of electrical applications.

Elasticity

Elasticity refers to the ability of a metal to return to its original form after being subjected to force. CNC metals generally exhibit great flexibility. The elasticity of aluminium 6061 is 68.9 GPa. It has excellent elasticity, making it ideal for CNC machining procedures.

Temperature Resistance

Temperature resistance or thermal resistance is a metal’s ability to resist the passage of heat. Aluminum 6061 is very temperature resistant. As a result, it does not overheat when exposed to high temperatures, making it ideal for usage in CNC machined vehicle components.

Material Hardness

Aluminum 6061 is a strong metal alloy due to its high strength-to-weight ratio. It has a high hardness, which is why it is utilized in CNC machining to produce very durable components for a variety of applications.

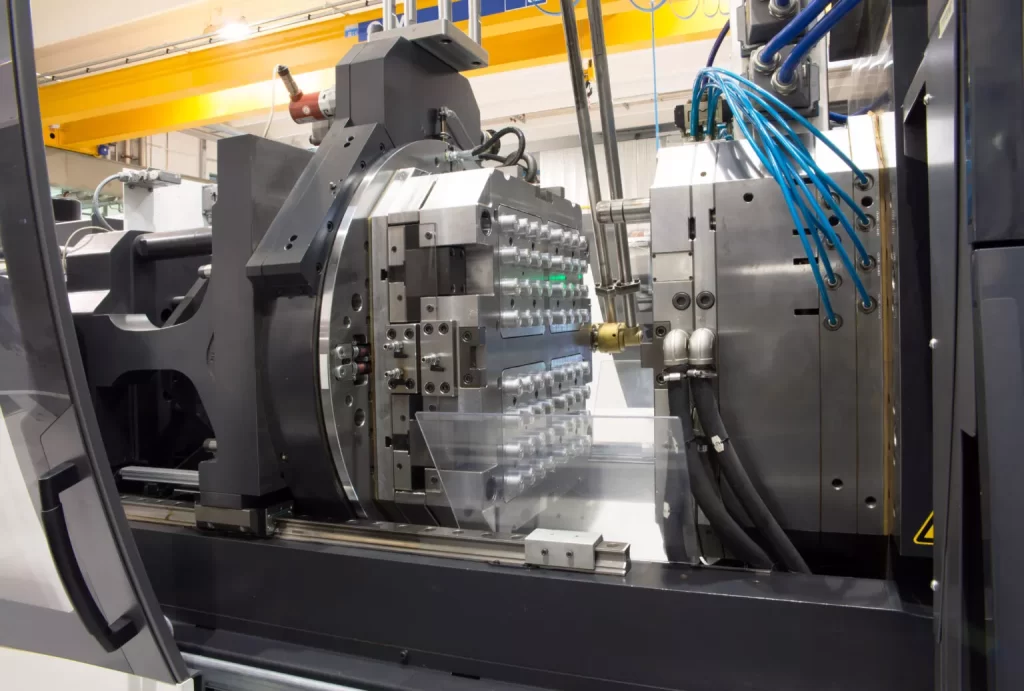

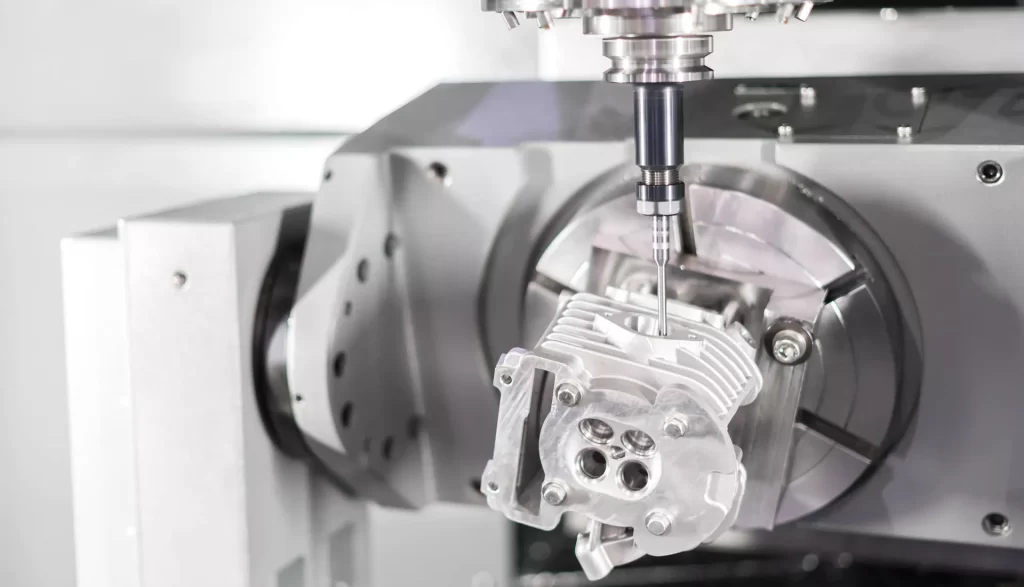

CNC Machining Techniques For Aluminum 6061 Parts

CNC Machining Aluminum 6061: The Process

CNC machining aluminum 6061 entails a series of precise stages that convert raw materials into final products of extraordinary precision and quality. Here’s an overview of the standard CNC machining process for aluminum 6061:

Design and Programming:

The procedure starts with designing the component using CAD software. Once the design is complete, Computer-Aided Manufacturing (CAM) software is used to create toolpaths and machining instructions based on the parameters.

Material Preparation:

Aluminum 6061 stock material is chosen depending on the part’s size and specifications. To maintain stability during machining, the material is fastened to the CNC machine bed via clamps or fixtures.

Machining Operations:

The component design and machining strategy determine which machining operations are done, such as milling, drilling, turning, and threading. High-speed cutting tools, usually composed of carbide or high-speed steel, are used to remove material precisely and efficiently.

Finishing Operations:

After the basic machining operations are completed, finishing techniques including deburring, surface milling, and polishing may be used to obtain the required surface finish and dimensional accuracy.

Inspection and Quality Assurance:

After machining and finishing, the components are thoroughly inspected using precision measurement instruments including callipers, micrometers, and coordinate measuring machines (CMMs) to verify they satisfy the tolerances and quality requirements.

Applications for CNC Machined Aluminum 6061 Parts

1. Aerospace Industry: Aluminum 6061 parts are widely used in aircraft components, structural frames, and aerospace applications because of their lightweight design and excellent strength-to-weight ratio.

2. Automobile Industry: CNC machined aluminum 6061 parts are used in vehicle prototypes, engine components, suspension systems, and performance enhancements due to their durability and performance characteristics.

3. Electronics Manufacturing: Aluminum 6061’s electrical conductivity and thermal characteristics make it an ideal material for heat sinks, electronic enclosures, and other electronic components that need efficient heat dissipation.

4. General Engineering: Because of its flexibility, machinability, and cost-effectiveness, CNC machined aluminum 6061 parts are used in a variety of engineering applications, including industrial equipment parts, consumer items, and architectural components.

Best Practices for CNC Machining Aluminum 6061 Parts

Optimize tool selection:

Select cutting tools made particularly for machining aluminum, such as carbide end mills with high helix angles and sharp edges. To enhance tool life and performance, consider aspects such as shape, coating, and material composition.

Control Cutting Parameters:

To improve chip formation and avoid tool wear, adjust cutting parameters such as spindle speed, feed rate, and depth of cut. To reduce heat buildup and preserve surface integrity, aluminum 6061 is generally machined at high spindle speeds with light cuts.

Use Coolant or Lubrication:

Use coolant or lubrication systems to disperse heat and increase chip evacuation when milling. This helps to avoid built-up edges, lowers tool wear, and improves surface finish quality.

Minimize Tool Path Overlap:

Optimize tool paths to reduce excessive tool retractions and overlaps, therefore lowering machining time and increasing efficiency. Use modern CAM software with optimization tools to create efficient tool paths that are suited to the part’s exact shape.

Consider Materials Handling:

Use correct fixturing and work holding procedures to secure the aluminum 6061 material during milling. Effective clamping mechanisms and smart component orientation reduce vibration, noise, and material deflection, leading to higher machining accuracy.

Implement post-machining treatments:

Consider post-machining treatments like anodizing, powder coating, or surface treatment to improve the completed components’ aesthetics, corrosion resistance, and usefulness.

Summary:

CNC machining aluminum 6061 material parts provide several advantages for producers looking for high-performance components with superior mechanical qualities and production efficiency. Companies may shape the future of precision manufacturing by knowing the specific properties of aluminum 6061, using suitable machining processes, and adhering to best practices.