Sheet Metal Bending is regarded as one of the most common manufacturing techniques and is considered as a fundamental process in metal fabrication. It is mainly because it allows the creation of complex shapes and structures from flat sheets of metal. There are wider industries in which the technique is being used such as development of simple brackets for intricate automotive components, in aerospace industry etc. In this article, the main purpose is to explore the basic concept behind sheet metal bending, its purpose, working principle and advantages that the technique offers. As a manufacturer, you will be able to address the different problems you might face while performing sheet metal bending once you go through this article.

Definition of Sheet Metal Bending

So starting off, let’s talk about what exactly sheet metal bending is. It is a form of manufacturing in which a flat sheet of metal is bent along a straight axis upto plastic deformation stage. Plastic deformation is the stage where the material does not come back to its original state under the action of external force. This process of sheet metal bending is usually done by a press brake that has variable pressure selections you can choose from.

Purpose of Sheet Metal Bending

As stated earlier as well, sheet metal bending is widely being used in multiple industries as a tool of manufacturing to create parts and components with specific geometries and functionalities. Bending allows manufacturers to produce a part in a single piece that helps in retaining the structural strength of the part. It is commonly used in various industries such as automotive, aerospace, construction and electronics to produce chassis, body parts, encasements and brackets.

Working Principle of Sheet Metal Bending

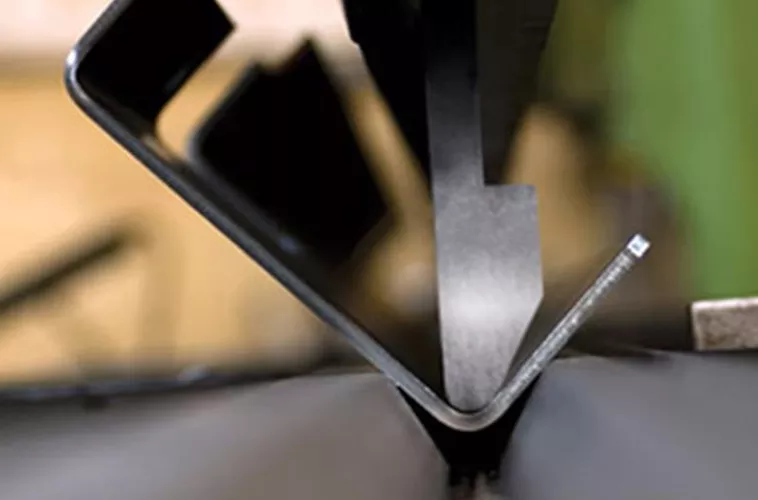

Plastic deformation as stated previously too, is the stage at which the material under stress does not come back to its original state. This is governed by the type of metal being used and the elastic limit. In sheet metal bending, this exact principle is utilized which is basically using a press brake that has a lower die and an upper tool which is called a punch. Force is applied on the sheet using the punch that pushes the sheet into the shape of the die that eventually results in the required component with its shape. Techniques of the sheet metal bending can be variable as per the required application.

Advantages of Sheet Metal Bending

There are a lot of advantages that are important to note when it comes to sheet metal bending owing to the manufacturability. Some of them are:

Versatility: When it comes to variations in terms of shapes and sizes, sheet metal bending offers a wider range thus making it very suitable for various applications.

Cost-effectiveness: For small and medium-sized production, sheet metal bending is quite cost-effective than other methods such as casting or machining.

Accuracy: This process can provide better accuracy as it does not involve joining of different surfaces and finished product are made in a single piece.

Strength: For structural applications such as brackets, bending can improve the structural strength.

Efficiency: Modern brake press technology is less time-consuming and once automated it can significantly reduce the production time.

Examples of Sheet Metal Bending

There are various industries in which sheet metal bending can be used, some of the examples are:

Automotive: Multiple automotive components especially body parts including chassis and fenders for automobiles utilize bending as a viable manufacturing technique.

Aerospace: This technique can often be used in making of wings or fuselage of aircrafts.

Electronics: For electronic devices, encasements and enclosures are manufactured using sheet metal bending.

Construction: Multiple architectural components such as roofs and windows can be made which are crucial in construction.

Techniques of Sheet Metal Bending

There are multiple techniques that significantly impact the overall sheet metal bending process, some of the key techniques and factors are mentioned below:

Air Bending: This technique involves the punch to force the metal sheet into the die present at the bottom to form the required shape. This is applicable especially for more ductile metals.

Bottoming: In this technique, the die is shifted into the metal sheet which is supported by the punch, this is efficient when you have to deal with tight tolerances.

Coining: This is a process in which both the punch and the die both apply force onto the metal sheet. This method is important when specific patterns are to be pressed alongwith the shaping process.

Rotary Bending: In this process, metal sheets are rolled between rollers to form cylinders or vessels that can be effective in producing circular or cylindrical components.

Factors Influencing Sheet Metal Bending

There are multiple factors that influence the overall process of sheet metal bending, some of these factors are briefly explained below:

Material Properties: Metals that have better malleability and ductility such as aluminum, copper are much easier to bend rather than those which are brittle such as stainless steel.

Tooling Design: Punch angle, die width and orientation of the tool are different factors that impact the tooling design which ultimately impact the formed product.

Bend Allowance: This is the limit at which the maximum bend a sheet metal can undergo. This allowance needs to be calculated very intelligently as it can impact the end-product.

Springback: This is a factor that is mainly governed by the principle of plastic deformation. When a metal is subject to plastic deformation, it maintains its deformed shape but in springback the metal does not reach its plastic limit and comes back to original state.

Conclusion

In conclusion, it is safer to say that sheet metal bending is a crucial technique being widely used in manufacturing process. There are various advancements being made around the globe in this field and the latest improvements include the automation of these processes. This evolution of sheet metal bending can open new avenues for innovation in product design and development. As a manufacturer, this article serves as a proper guide to sheet metal bending and the factors mentioned above that can impact the overall process need to be kept in mind.