Automotive sheet metal manufacturing harnesses various techniques. And materials to produce high-quality body panels and parts integral to auto construction and restoration. This complex process involves precisely shaping sheet metal to form various auto components, including fenders and body panels. Materials range from cold-rolled steel for strength and durability to specialized alloys that resist rust and wear.

Sheet metal gauge, a crucial factor, dictates the thickness and application of each panel, ensuring compatibility with different automotive designs. Metal fabrication techniques, both traditional and advanced, play a pivotal role in shaping these components. Sheet metal fabrication stands out as a core method in the automotive industry. This blog post delves into the diverse techniques and materials utilized in automotive sheet metal manufacturing.

Readers will gain insights into the nuances of metal fabrication. From selecting quality sheet metal for car restoration to the intricacies of creating durable, aesthetically pleasing auto body parts. Whether you’re a professional in a body shop or a hobbyist interested in automotive sheet metal fabrication. This post provides valuable knowledge on enhancing your craft.

What is Automotive Sheet Metal?

Automotive sheet metal refers to the cold-rolled, flat steel used in manufacturing car parts. Precision sheet metal crafting produces durable, original metal for auto bodywork, including quarter panels and rust repair sections.

Auto sheet metal parts are vital for auto body shops, offering replacement sheet metal for comprehensive vehicle restoration and maintenance. Best sheet metal practices ensure automotive part longevity and fit. Crafted from cold-rolled steel, automotive sheet metal parts are essential in maintaining a car’s structural integrity, aiding in aesthetic and functional vehicle repairs.

Different Types of Techniques and Materials

Understanding the diversity in metal fabrication techniques is crucial. Especially in sectors like the automotive industry. These methods enable the creation of essential components, from the car’s body to intricate structural components. Each technique offers unique advantages and applications.

Making them indispensable for crafting original sheet metal parts or replacement panels. Below, we delve into various methods for shaping cold-rolled flat steel. OR other types of sheet metals into functional automotive components.

Techniques:

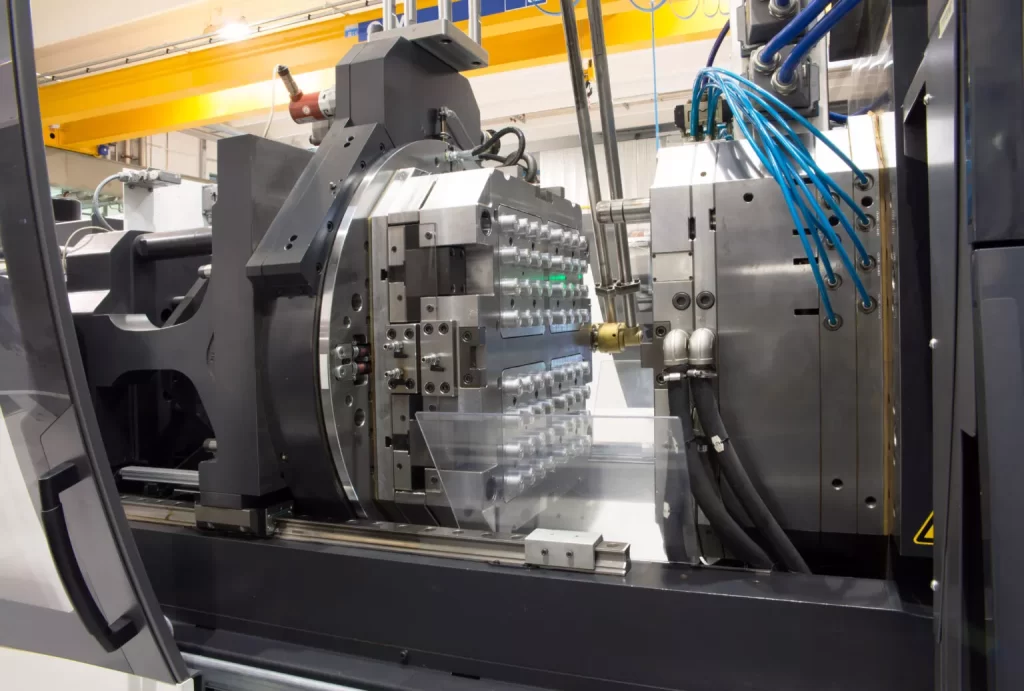

Stamping: This technique involves pressing flat sheets of metal, typically 20 or 22 gauge, into desired shapes. It’s pivotal for manufacturing large panels that form the car’s body. Stamping allows for high-volume production, ensuring efficiency in creating original sheet metal components.

Hydroforming: Hydroforming uses high-pressure fluid to shape metal within a mold. It’s beneficial for crafting complex shapes in automotive components, offering precision without compromising the metal’s integrity. This method is ideal for parts requiring 22-gauge sheet metal, enhancing services for the automotive industry.

Roll Forming: Roll forming bends metal gradually through a series of rolls. This method is perfect for creating long, consistent shapes in cold rolled flat steel, often used in structural components of a vehicle. It ensures uniformity and strength in the parts manufactured.

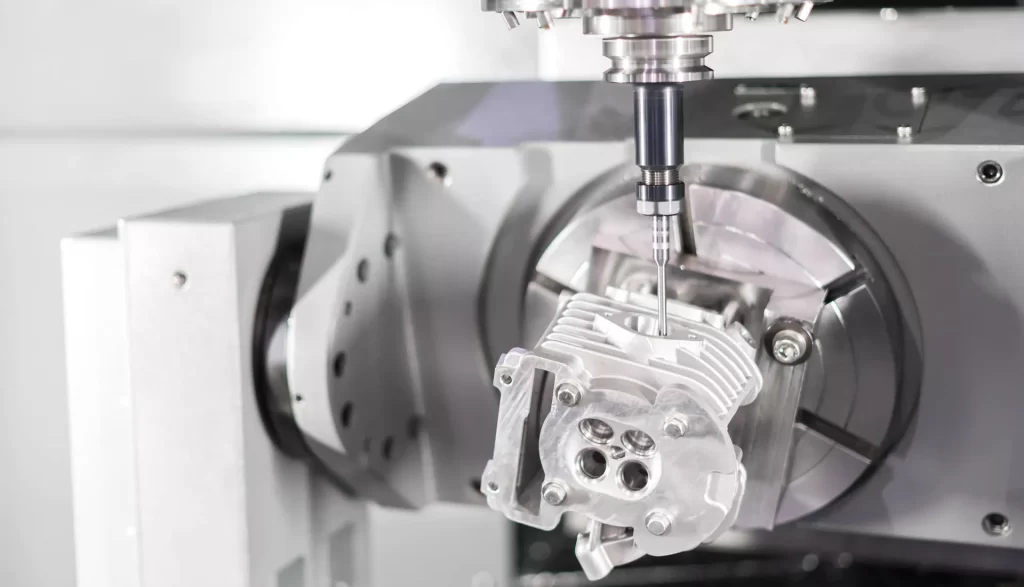

Laser Cutting: Laser cutting employs a high-powered laser to cut precise shapes in metal, ideal for intricate designs or automotive components requiring exact dimensions. It provides a high level of precision, making it suitable for both original sheet metal and replacement panels.

Welding: Welding joins metal parts together using heat. It’s a fundamental technique in assembling structural components of a car’s body, ensuring durability and safety. Welding services are crucial for both creating new parts and repairing existing ones in the automotive industry.

Deep Drawing: Deep drawing stretches metal into deep, irregular shapes. This method is used for components like fuel tanks or certain car body panels, utilizing both 20 and 22 gauge sheet metals. It allows for producing complex parts without sacrificing the metal’s strength.

Bending: Bending creates V-shapes, U-shapes, and channels in metal sheets. This technique is essential for forming parts of the car’s framework or structural components, offering versatility in using cold-rolled flat steel.

Punching: Punching creates holes or cut-outs in metal through a punch press. It’s a critical process for parts requiring ventilation or mounting points, utilized extensively in the automotive industry. Punching ensures precise holes in both original sheet metal and replacement panels.

Each technique plays a significant role in metal fabrication, particularly in the automotive industry. They enable us to craft everything from the car’s body to detailed automotive components precisely and efficiently. Employing the right tools and methods allows for high-quality sheet metal work. Meeting the demands of modern automotive design and safety standards.

Materials:

Understanding the variety of materials available is crucial for achieving optimal results in any project, especially in the auto industry. Each material offers unique properties, from durability to corrosion resistance, impacting everything from safety components to fuel efficiency. Choosing the right material and proper gauge is essential for metal fabrication services, panels manufactured, or tools to complete a task.

1. High-Strength Steel: High-strength steel provides exceptional durability, making it the go-to for safety components in the auto industry. Its ability to withstand extreme conditions ensures that parts made from this material contribute significantly to vehicle safety. When it comes to metal fabrication services, utilizing a lower gauge number of this steel results in stronger, more resilient panels.

2. Advanced High-Strength Steel (AHSS): Advanced High-Strength Steel (AHSS) stands out by offering superior strength at a lighter weight, enhancing fuel efficiency without compromising safety. Its application is pivotal for the auto industry. Where balancing weight and durability is crucial. A thinner gauge can be used without losing structural integrity for panels manufactured with AHHS. Showcasing the importance of selecting the proper gauge for your type of project.

3. Aluminum: Aluminum is prized for its lightweight and corrosion resistance, boosting fuel economy and overall vehicle performance. Its versatility in manufacturing ranges from 20 gauge sheets for body panels to thicker gauges for structural components. This makes it an invaluable material in auto construction.

4. Magnesium Alloys: Magnesium alloys offer an even higher strength-to-weight ratio than aluminum, pushing the boundaries of automotive design and performance. Utilizing magnesium alloys allows for lighter vehicles with improved dynamics. When crafting parts made from these two materials, understanding the nuances in gauges and fabrication techniques is key to maximizing their benefits.

5. Titanium: Titanium, known for its exceptional strength, lightweight, and corrosion resistance, is often reserved for high-performance and luxury vehicles. Its usage requires specialized tools to complete the work, highlighting the role of expertise in working with such advanced materials. Despite its higher cost, the benefits of titanium in critical components justify the investment for those demanding the utmost in performance and durability.

6. Carbon Fiber Reinforced Polymers (CFRP): Carbon Fiber Reinforced Polymers (CFRP) are revolutionizing the auto industry by offering unparalleled strength and lightness. This material is ideal for high-performance vehicles, where every kilogram saved enhances speed and efficiency. Crafting CFRP parts demands precision and experience, ensuring each component maximizes the vehicle’s performance potential.

7. Stainless Steel: Stainless steel is extensively used for its excellent corrosion resistance, particularly in exhaust systems and decorative trims. Its durability makes it suitable for parts that require longevity and aesthetic appeal. For lower gauge exhaust pipes or 20 gauge decorative panels, stainless steel’s versatility makes it indispensable in the auto industry, underscoring the importance of metal fabrication services tailored to each project’s requirements.

Final Thoughts

In automotive sheet metal manufacturing, panels are manufactured using diverse techniques, catering to different design and durability needs. Commonly, materials range from 16 gauge to the more pliable 18 to 22 gauge in thickness, balancing strength, and flexibility. Patch panels, essential for repairs, often utilize 18 gauge, ensuring a sturdy yet workable solution.

This variety allows for the creating of quality parts that meet specific vehicle requirements. At the heart of this industry is an experience working with sheet metal for auto applications, showcasing a blend of craftsmanship and technological precision. Reach out to us today for solutions that embody innovation and quality in automotive sheet metal manufacturing.