Plastic Injection Molds

Rapid Manufacture provides design for manufacturability (DFM) feedback to help optimize your injection mold production design. Our team can review your design and provide recommendations to improve manufacturability, reduce costs and ensure successful mold production.

Injection Mold Company in China

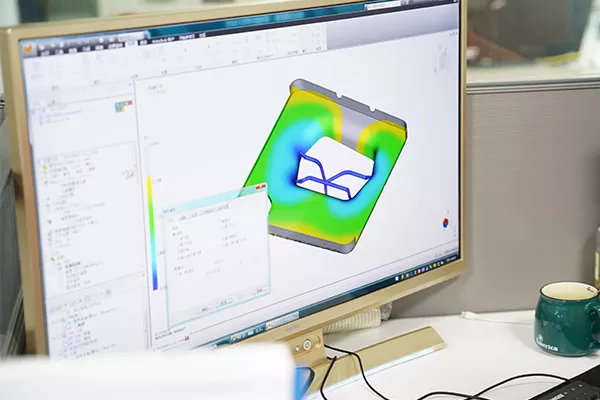

After a custom plastic part has been designed, making a plastic injection mold is the first step in creating custom molded parts. In combination with skilled mold designers, software technology, and the use of expensive CNC machinery, Rapid Manufacture builds molds for plastic injection that are used to produce high quality molded plastic parts.

Your mold is not only the largest up front investment in your injection molding project, its construction is also the most significant factor in the quality of the parts it will produce. If you are searching for an injection molding company in the USA to work with it’s important that you find a supplier with in-house mold manufacturing capabilities to insure that you have single source responsibility on the project timeline and quality of your parts.

Our injection molding experts look forward to working with you on your mold build project as the next step toward manufacturing your custom molded parts. If you’re looking for an injection mold supplier, we have you covered.

Injection mold instant quotation

Rapid Manufacture is a custom part production solutions provider dedicated to manufacturing cost-effective plastic injection molds, molded parts, and continuously improving our processes to provide high value to our customers.

Whether you are looking to manufacture molds or have us provide you with finished parts, we are your first choice. Immediately upload injection mold design drawings to our instant quotation system to obtain mold design analysis and quotations.

Rapid Manufacture’s Mold Making Process

Mold Design

Rapid Manufacture is an injection mold supplier with decades of experience in mold design. Our molds are precise, durable, and designed to be efficient in the manufacturing process.

CNC Machining

Rapid Manufacture CNC machines are very precise and have high tolerances. This service is ideal for prototyping and producing actual parts made of metal, resins or a combination of the two.

Mold Making

We offer mold-making services at competitive rates and deliver in short lead times. All processes are performed under strict quality guidelines and the supervision of mold engineering experts.

Materials for Mold Making

Tool steel is a carbon and alloy steel with high hardness, wear resistance and toughness, making it suitable to withstand the stresses and requirements of die production.

Subtypes:

- P20

- H13

- S7

- NAK80

- 718

- 718H

- 738

Stainless steel can withstand higher temperatures compared to some other mold materials. This property makes it suitable for plastic molding processes that involve elevated temperatures or rapid temperature fluctuations.

Subtypes:

- 136

- 301

- 303

- 304

- 316

- 316L

- 420

Aluminum may not possess the same hardness and wear resistance as tool steel, aluminum molds offer distinct advantages in terms of cost, lightweight construction, and thermal conductivity.

Subtypes:

- 5052

- 6061

- 7075

In-House Mold Builds

All of Rapid Manufacture customer molds are built right here inside of our Michigan facility. Our mold build area is staffed with experienced designers and machinists using the most modern software and CNC machinery. After customer part designs are finalized and approved for manufacturing our team will design and build robust trouble free plastic injection molds for your production.

Why Choose Ecomolding As Your Partner?

In order to control costs, we continue to optimize and upgrade the factory management system, which helps us provide lower prices, so that we can greatly reduce factory management costs and provide customers with more professional customized injection molding services. We have ISO9001-2008 certificate, which guarantees the quality of our products. Although some materials are more expensive in China, we still have a very good price advantage for large quantities of customized plastic parts.

In addition, our sales team has extensive project experience and is able to provide a high level of service and communication throughout the entire process. This is our advantage over other Chinese injection molding companies.

Strategic partnering with clients

Strategic partnering with clients is crucial for the success of any joint project. When you talk, we listen. Only by listening can we fully understand your needs. Only by fully understanding your needs can we fulfill them.

Ongoing client communication is essential. If there are hurdles along the way, we can troubleshoot and problem-solve together and thereby achieve goals faster.

One-Stop Services

Maximizing your investment is our goal. Rapid Manufacture’s outlay cost planning process includes design, manufacturing, injection molding, assembly, and logistics.

The entire process is carefully designed to give our customers the best possible ROI. We optimize your investment according to what is essential and what is not.

Don’t hesitate, please contact us to get an instant injection molding quote!

Let's get started on your new injection mold project!

Get Your Free Quote About Plastic Injection Molding Mold Today.With instant injection molding quote online.