Metal Stamping Services

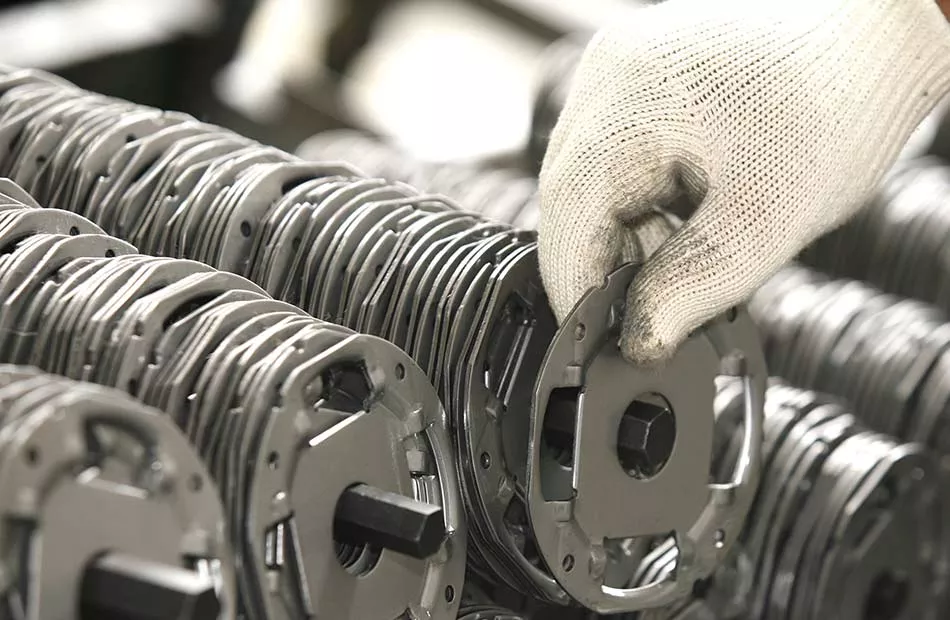

Metal stamping encompasses single hit, progressive, and transfer stamping. Rapid Manufacture provides high efficiency, speed and quality for complex high and medium volume metal stamping including but not limited to punching, blanking, bending, coining, flanging and embossing.High Quality Metal Stamped Parts From Short Runs To Production In The Millions.

High-precision metal stamping and manufacturing

Rapid Manufacture provides leading OEM and tier manufacturers across the globe with progressive die heavy and high-speed metal stamping services. We support custom, high-volume production requests for precision, electrical connectors, contacts, and various other electrical and non-electrical component parts. We offer in-house support of rapid prototyping, tool design and tool production, waterjet, and assembly services. We’re known for investing in our industry’s top stamping production technology and the deployment of strong quality controls through our signature in-line/off-line camera vision systems and sensor technology. Our continual equipment investments are what enable us to meet new and evolving industry developments and greater production efficiencies, reach competitive pricing and achieve better product results.

Online Quotation for Metal Stamping Services

Rapid Manufacture produces custom metal stampings in a variety of materials, including copper, brass, stainless steel and steel alloys. We offer stampings in production volumes up to one million+, maintained to tight tolerances, and with competitive lead times. Get started using our online quoting system to take advantage of our precision metal stamping services. Our project managers and experts personally review and manually quote each metal stamping project to ensure we meet your unique needs while providing a fast, easy manufacturing experience.

The Stamping Process

Metal stamping is a manufacturing process in which coils or flat sheets of material are formed into specific shapes. Stamping encompasses multiple forming techniques such as blanking, punching, embossing, and progressive die stamping, to mention just a few. Parts use either a combination of these techniques or independently, depending on the piece’s complexity. In the process, blank coils or sheets get fed into a stamping press which uses tools and dies to form features and surfaces in the metal. Metal stamping is an excellent way to mass-produce various complex parts, from car door panels and gears to small electrical components used in phones and computers. Stamping processes are highly-adopted in automotive, industrial, lighting, medical, and other industries.

- Blanking—Blanking removes a workpiece from the original metal to create your designated form. It is the opposite of punching as the removed metal becomes the shape or blank.

- Punching—Punching uses a die and a punch to cut sheet metal into your designated shape. Excess material is dispelled from the surface, and the remaining form creates your final part.

- Bending— Metal sheet is bent and formed to match your shape specifications. The most common forms are L, U, or V-shapes as this process is accomplished by bending a material around a single axis.

- Drawing—Using a compressive force, sheet metal is formed into a cavity or around the desired shape. Drawing is also sometimes referred to as forming.

- Embossing—Embossing uses a die to apply a shape onto metal material, imprinting the pattern or design onto the workpiece.

Metal Stamping Capabilities

We have multiple precision metal stamping presses (45 tons to 800 tons) operating on an advanced press control system that utilizes in-mold sensor technology to meet low to high volume production needs and protect your stamping dies. Our stamping range is used across a variety of industries, from producing 5mm parts for industrial automation to 31-inch parts for fitness equipment.

- ERP-system manages production schedules and quality inspections

- In-house tool room builds progressive stamping dies that perform multiple operations including in-die assembly and tapping

- Sensor technology protects stamping dies during production and ensures operations are functioning properly

- Greater control and flexibility of the stroke in the servo press delivers metal parts more quickly and with greater precision

- Detailed quality inspections are performed on the stamping floor and in the quality lab.

- The completion of metal parts is performed in-house with sub-assembly services, finish and line ready packaging.

- In-house die maintenance performs repairs and modifies dies within set deadlines

Types of Stamping

We offer single and multistage, progressive die, deep draw, fourslide, and other stamping methods to ensure the most effective method for manufacturing your products. Rapid Manufacture’s experts can match your project with the appropriate stamping by reviewing your uploaded 3D model and technical drawings.

- Progressive Die Stamping uses multiple dies and steps to create deeper parts than would typically be achievable through single dies. It also enables multiple geometries per part as they go through various dies. This technique is best suited to high volume and large parts such as those in the automotive industry. Transfer die stamping is a similar process, except progressive die stamping involves a workpiece attached to a metal strip pulled through the entire process. Transfer die stamping removes the workpiece and moves it along a conveyor.

- Deep Draw Stamping creates stampings with deep cavities, like enclosed rectangles. This process creates rigid pieces since the extreme deformation of the metal compresses its structure into a more crystalline form. Standard draw stamping, which involves shallower dies used to shape the metal, is also commonly utilized.

- Fourslide Stamping shapes parts from four axes instead of from one direction. This method is used to manufacture small intricate parts including electronics components such as phone battery connectors. Offering more design flexibility, lower production costs, and faster manufacturing times, fourslide stamping is popular in aerospace, medical, automotive, and electronics industries.

- Hydroforming is an evolution of stamping. Sheets are placed on a die with a bottom shape, while the upper shape is a bladder of oil that fills to high pressure, pressing the metal into the shape of the lower die. Multiple parts can be hydroformed simultaneously. Hydroforming is a quick and accurate technique, though it requires a trim die to cut the parts out of the sheet afterward.

- Blanking cuts pieces out from the sheet as an initial step before forming. Fineblanking, a variation of blanking, makes precise cuts with smooth edges and a flat surface.

- Coining is another type of blanking that creates small round workpieces. Since it involves significant force to form a small piece, it hardens the metal and removes burrs and rough edges.

- Punching is the opposite of blanking; it involves removing material from the workpiece instead of removing material to create a workpiece.

- Embossing creates a three-dimensional design in the metal, either raised above the surface or through a series of depressions.

- Bending happens on a single axis and is often used to create profiles in U, V, or L shapes. This technique is accomplished by clamping one side and bending the other over a die or pressing the metal into or against a die. Flanging is bending for tabs or parts of a workpiece instead of the whole part.

Metal Stamping Materials

- Stainless Steel

- Aluminum

- Cold Rolled Steel

- Hot Rolled Steel

- Pre-Galvanized Steel

- Annealed Steel

- Brass

- Copper

- Plastic

Metal Stamping Parts Applications

Rapid Manufacture manufactures precision stamping products based on your project’s exact specifications. Our tooling and precision metal stamping experts can create stand alone or supplemental parts and components. Our custom metal stamping services assist in creating a wide range of products for numerous industries including:

- Electronic Terminals

- Sensor components

- Yokes

- Thrust washers

- Heat sinks

- Printer cartridge blades

- Medical components

- Inserts

- Fuse clips

- Brackets

- Contacts

- Covers

- Latches

- Furniture parts

Metal Finishing Options

- Pre-Plating, Post-Plating and Spot Plating

- Powder Coating & E-Coating

- Electropolishing

- Deburring

- Heat Treating

- Sanding, Grinding, and Buffing

- Cleaning

Why Rapid Manufacture?

We’re a niche stamped metal parts manufacturer whose mission is to “Just Be Ready.” We provide metal stamped parts and additional stamping solutions for all complex applications in a timeframe that promises client success.

We’re able to provide short-run metal parts and medium run metal parts faster than the competitor because of our in-house tooling system. Our process is maintained for each customer and for the life of every part produced.

Talk with our experts today and let us help you figure out the best solution

Whether you’re an engineer starting a project and seeking high volume-high value metal stamping capabilities, or a purchasing professional looking for a quality-driven metal stamping manufacturer, let us quote your metal stamping requirements today.