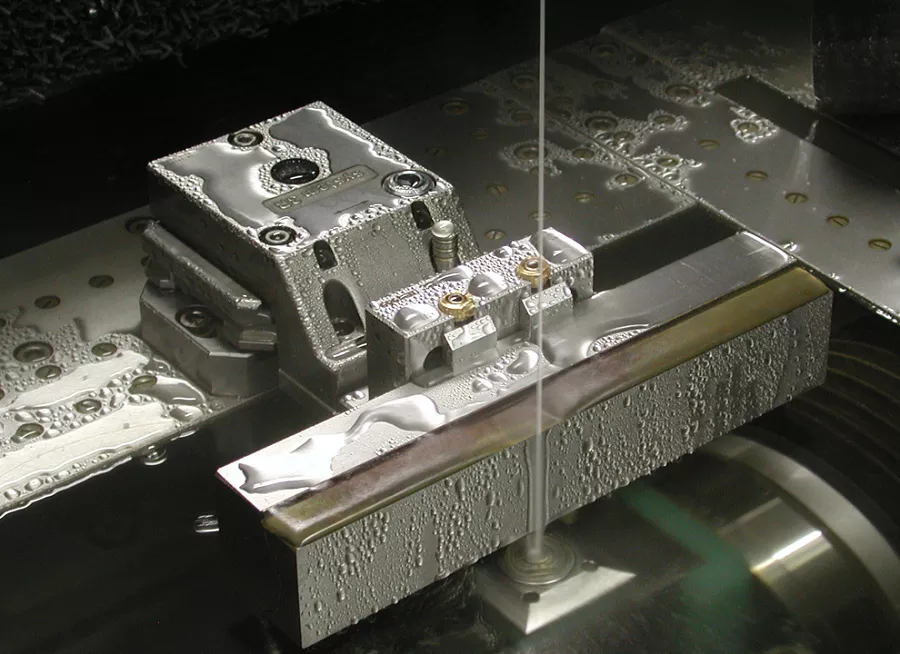

Wire EDM Machining Service

We Provide The Best Wire Cutting Machining Services In China. Our Advanced Equipment Can Create Components With Extremely High Tolerances,Using Our Modern Wire EDM Equipment And A Lean Manufacturing Process, We Can Build The Most Complex, Delicate Parts And Geometries With Guaranteed Quality – Whether You Need A Single Prototype, A Small-Scale Manufacturing Run, Or A Large Order Consisting Of Tens Of Thousands Of Components.

Providing excellent wire-cut EDM services

At Rapid Manufacture, we have been using wire EDM technology since 2003 to make tools and molds for our other manufacturing processes. A few years later, we expanded our EDM department to provide full production capabilities for customer projects.

Today, we utilize a range of state-of-the-art Mitsubishi wire EDM machines to produce molds and custom 2D metal parts for our customers. We continuously upgrade wire EDM processing technology to ensure we have the most advanced features.

Most of our EDM systems are used for customer part production, with a few dedicated to tool and mold manufacturing. However, we can expand our production capabilities as needed and transition some or all of our tool and die EDM processes to parts production to deliver high-volume parts orders as quickly and efficiently as possible. This flexibility benefits both us and our customers.

Precision Wire EDM Services, One-Stop & On-Demand

Experience Rapid Manufacture’s online quotation system, which helps you quickly analyze parts and get real-time quotes, and order customized high-performance and high-quality wire-cut parts at low prices.

Our climate-controlled facility ensures consistency and accuracy every time the wire is cut and every part is made. Rapid Manufacture has technologically enhanced wire-cut electrical discharge machines. These exceptional wire EDM machines are capable of machining parts with extreme precision and high cutting speeds while maintaining strong process control. Additionally, we can precisely achieve dimensional accuracy of +/-0.001mm.

Benefits Of Wire EDM Services

Wire EDM provides some of the closest machining tolerances available today. Dynamic Design & Manufacturing is no stranger to working within +/-0.0001” tolerances, which typical wire EDM tolerances are smaller than a human hair. The advantage of using our state-of-the-art wire EDM machines is benefit of such exact cutting with each piece. Along with the advantage of a precise cutting tolerances, wire EDM services offers additional benefits such as:

- Consistency – conventional cutting tools can wear down or break throughout the cutting process, which results in small inconsistencies in the final product. Wire EDM machines cycle new wire between spools to product consistent quality.

- Material Compatibility – wire EDM can make exact cuts on wide variety of materials than other cutting services. Our wire EDM machine can machine harden metals like graphite or softer metals like copper.

- Eliminates Finishing – Dynamic Design & Manufacturing produces ultra-fine finishes which do not require additional surface treatment.

- Simultaneous Cutting – wire EDM can cut through stacked materials to produce identical OEM components at the same time

Wire EDM Services Can Cut Your Production Costs

Wire EDM is an extremely versatile option that is the preferred choice by many industry professionals for certain complex shapes. Ideal for Oil and Gas industry projects, we also regularly provide EDM machining services to robotics developers, the medical equipment industry and the aerospace sector. Wire EDM is the perfect solution, particularly if you wish to use exotic metals or other difficult to machine metals.

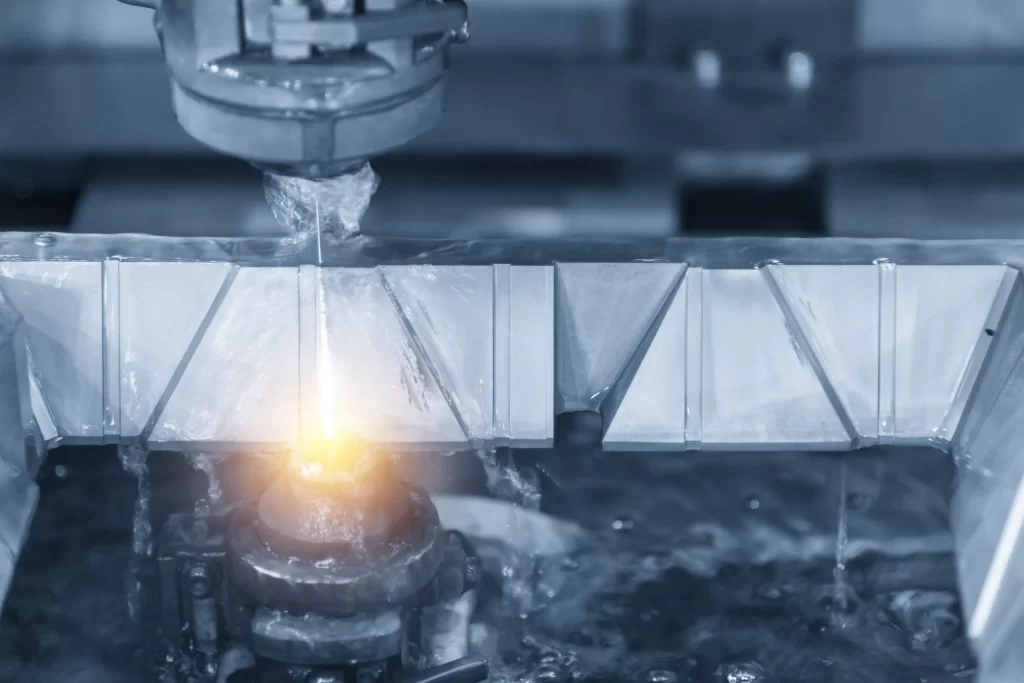

he Wire EDM Cutting Process – How It Works

The Materials Used For Wire Cutting Machining

Wire cut EDM can be used to cut any electrically-conductive material. Even extremely hard steel alloys and other such materials that are difficult to mold or cut without first adding heat can be cut with electrical discharge machining.

EDM wire machining is perfect for cutting very costly materials like tungsten. Due to the high cost of these materials, precision is important for minimizing quality issues, and for minimizing wasted quantities of metal. EDM wire machining helps enhance cost-efficiency for these exotic metals.

Some of the most common materials used with this method include:

- Tungsten

- Brass/bronze

- Carbon graphite

- Copper

- Carbon steel

- Stainless steel

- Inconel

Wire EDM Applications

We have expertise in working with hard and soft metals. Our wire EDM cutting can be applied to Aluminum, Brass, Bronze, Copper, Spring Steel, Stainless Steel, Steel and Titanium, which are super alloys and difficult metals to machine. The wire EDM cutting process can also cut most simple or complex 2D shapes including thin walls and cutouts, intricate openings and sharp corners. Our equipment utilizes 0.004″-0.012″ diameter wire to cut metals that are too hard for conventional machining.

- Punches.

- Arrays.

- Extrusion dies.

- Precision keyways.

- Plastic injection molds.

- Cutting dies.

- Stamping and forging matrix.

- Tools.

- Dies for sintering.

- Special applications.

Why Choose Our Precision Wire EDM Services?

Quality Assurance

When it comes to machine parts with precision and by following the highest quality standards that sometimes exceed the quality limits, Rapid Manufacture has a reputation for this and the reason why our customers choose our wire-cut EDM services. The quality we maintain and enhance part after part is what convinces our customers to stay with us. With advanced technology and state-of-the-art wire EDM equipment, we are committed to giving you top-quality parts that can perform exceptionally.

Passion for Precision

Being passionate about the thing we do and the services we offer is what define us. That’s also one of the reasons behind our complete focus on successfully machining your complex designed custom parts. Most importantly, Rapid Manufacture always sticks to what promises it makes and is passionate about it. Being honest is a great part of this job, and we won’t make promises that we can’t keep.

Quality Control

Rapid Manufacture’s advanced quality control systems and a team of highly trained professionals ensure your parts will be machined in the right way. Our state-of-the-art wire EDM equipment and technologically enhanced techniques enable us to improve and enhance the quality of your parts on a continual basis. The in-depth knowledge of our engineers helps us ensure that your job is completed as described in your specifications.

Reliable On-Time Delivery

At Rapid Manufacture, our experienced staff with advanced monitoring equipment monitors the progress of every wire EDM parts production-related job on a daily basis. Our fully optimized schedule and machining processes enable us to increase production in cost-effective manners. We are able to resolve any potential problems before they arise, and these key factors enabled us to provide you with consistent and reliable on-time delivery.

Exceptional Capabilities

The most interesting thing about Rapid Manufacture is that we only present top-quality products and parts. Our machined parts will work in the perfect manners and operate consistently. With the perfect material selection ability, our machined parts can perform exceptionally over the long term and help your business increase both efficiency and productivity. Rapid Manufacture is capable of processing your ever Wire EDM-related need.

Excellent Services

Our team plays an important part in our success, and we are fast and responsive. We offer everything related to wire EDM, including specs, datasheets, or dimensions. We believe in offering you top-quality customer services whenever you need them.

Wire EDM Process

It’s important to remember that Wire EDM is an erosion process as opposed to other subtractive processes that rely on cutting. So, it has different surface properties that often rely on the number of passes (iterative cuts) for the optimum level of finish. Here’s how we go about it.

First Pass (Rough Cut)

A rougher finish to quickly achieve the design with a tolerance of +/- .002’. About 90% of wire EDM parts only need the first pass as the tolerance is acceptable for a lot of applications and surface finishing requirements.

Second Pass (Finishing Cut)

For more advanced applications, a second pass with more refinement can achieve tolerances of up to +/- 0.0005” along with a surface finish of 72 µin, which is almost indiscernible to the eye.

Third Pass (More Granular Details)

This is the most refined cut with the finest finish that is needed for highly sensitive applications like medical devices and aerospace components. The third pass can bring the surface finish down to 35 µin, which is more than needed for many wire EDM applications.

Ready to get started on your wire EDM machining project?

Just upload the drawings to our online quotation system to get a real-time quotation. Rapid Manufacture provides precision wire-cut EDM services and high-speed small hole EDM services worldwide. Our production experience and equipment capabilities allow us to take on any size or type of project and deliver it to you on time.