Electrical Discharge Machining (EDM) Services

Transform Your Ideas into Reality with Our Expert Services. Rapid Manufacture delivers precision, speed, and affordability for all your manufacturing needs.

High-Quality Electrical Discharge Machining

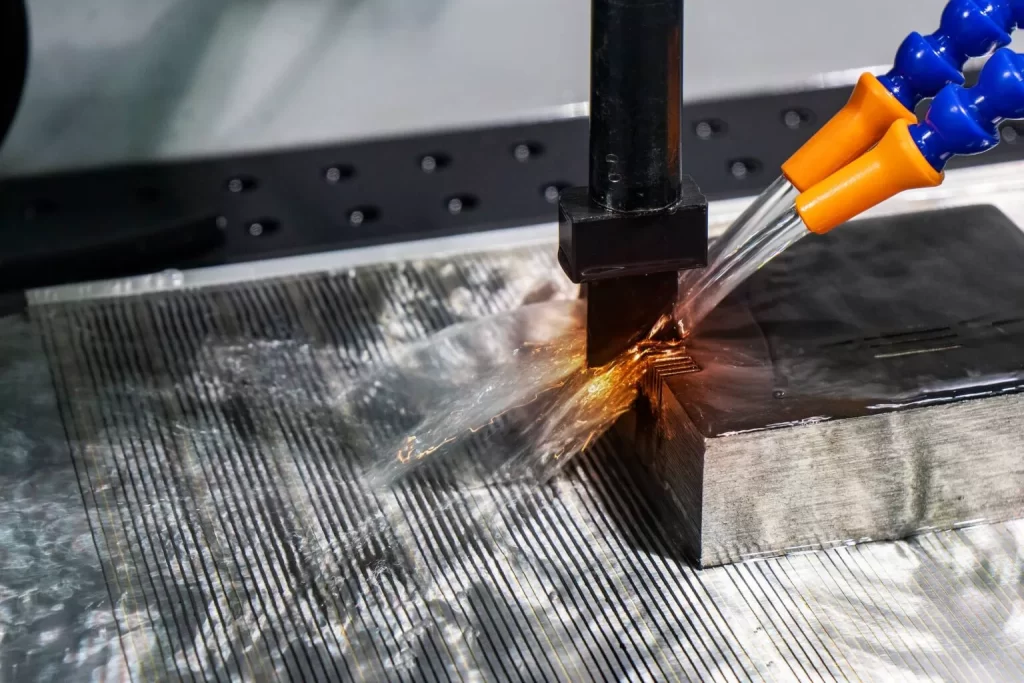

We focus on EDM technology and take EDM to new heights. With our precision sink EDM and wire EDM machines, we can manufacture your precision, small, complex parts reliably, promptly and cost-effectively.

Our state-of-the-art equipment and programming software give us the tools to complete complex projects with tighter tolerances and faster turnaround times than other facilities. Rapid Manufacture’s sink EDM services, wire EDM services and small hole EDM services are ideal for machining extremely hard materials with tight tolerances, small inside radii and complex shapes that cannot be machined by any other method.

Our EDM services have been used in mold, medical, aerospace, defense, automotive, electronic applications and other fields. Whether your project requires wire EDM or EDM, we can guarantee tight tolerances. Our EDM services can be combined with other machining services such as turning, milling, grinding, finishing, heat treatment, surface coating and assembly to form a complete end-to-end solution.

Electrical Discharge Machining (EDM) Capabilities

We are proud to offer best-in-class Electrical Discharge Machining (EDM) services. EDM is ideal for cutting complex contours and cavities that are difficult to machine with other cutting tools, and can also be used for quality control and inspection purposes. We offer RAM and wire EDM services with CNC control. Our machinists work with a variety of standard and specialty metals, including high-nickel alloys, carbon steel aluminum, chromium-based alloys, Inconel, Hastelloy, cobalt-chromium alloys and titanium. Our EDM work centers can accommodate workpieces of various sizes, including lengths up to 40″, widths up to 20″, and thicknesses up to 17″. We can machine workpieces to a precision tolerance of ± 0.0005″. We also offer many additional services to complement our EDM capabilities, including CAD services, CAM programming services, cellular machining, reverse engineering, and more. Our workloads range from single prototypes to medium-scale production and we provide quotes on a case-by-case basis. We comply with the highest industry standards such as ISO 13485:2016, AS 9100D and ISO 9001:2015, Nadcap AC7004, Non-routine Machining (EDM), Non-routine Machining (NJ), Non-routine Machining (OH).

Precision Electrical Discharge Machining (EDM) Services Quote Online

At Rapid Manufacture, we pride ourselves on our ability to handle multiple projects simultaneously, ensuring we finish on time and exceed your expectations. We have a team of highly qualified operators with decades of experience in precision machining. As a technology-driven CNC turning company, we have developed an AI-powered quoting platform that streamlines your ordering and manufacturing processes. Combining the advantages of the Internet with state-of-the-art equipment and the expertise of our team enables us to provide the highest quality processing services and results on time and on budget.

Five steps to get your ideas into products

Upload Your Design

We assure you that the design upload process to the online quotation system is safe and confidential. Your design will be kept confidential and will not be shared with any third parties. Simply upload your design file and, in addition to being analyzed by the system, our team will review it to ensure it's suitable for production.

Get Advice and Quote

After our team reviews your design, we will provide you with a detailed manufacturing cost quote. We will also provide expert advice on any potential design issues that may affect the final product. We are committed to providing you with the best service and support throughout the entire process.

Confirm and Manufacture

Once you confirm your order and approve your quote, Rapid Manufacture will begin manufacturing your product. Our team will keep you updated on progress and ensure everything goes as planned.

Quality Control

Before shipping your product, we will perform a thorough quality control check to guarantee that it meets our strict standards. Our goal is to ensure that you receive a high-quality product that meets your expectations.

On-Time Delivery

Rapid Manufacture will ship your product using a reliable and secure delivery service. We will provide you with tracking information so that you can monitor your order every step of the way. Our commitment to customer satisfaction is our top priority, and we strive to deliver your product on time and in perfect condition.

What are Electrical Discharge Machining (EDM) Services?

Electrical Discharge Machining (EDM) services involve the use of controlled electrical sparks to remove material from a workpiece, resulting in highly precise and intricate parts. EDM is a popular technique for shaping difficult-to-machine materials, such as hardened steel, carbide, or conductive composites. EDM services are valuable when:

- Working with hard materials. EDM services excel at machining materials that are difficult to process using conventional methods. The process is ideal for handling materials with high hardness or strength.

- Creating complex shapes. EDM is well-suited for producing intricate geometries and designs, as it does not rely on mechanical cutting forces. The process can generate intricate cavities, narrow slots, or sharp internal corners with ease.

- High accuracy and surface finish. EDM services offer exceptional accuracy and surface finish, making them ideal for applications where tight tolerances and high-quality surfaces are required.

- Minimal mechanical stress. Since EDM is a non-contact machining process, it minimizes the mechanical stress on the workpiece, reducing the risk of distortion or damage to delicate parts.

- Low volume production. EDM services can accommodate low-volume production runs efficiently, allowing manufacturers to deliver custom or limited-edition parts without a significant increase in cost.

Key Features of EDM Services

Precise and Detailed Machining

Superior Material Versatility

No Pre-Processing

Low Residual Stresses

Low Tool Wear

Benefits and Advantages of EDM Services

High precision

EDM can produce parts with very tight tolerances, making it ideal for precise and intricate parts.

Material versatility

EDM can be used on a wide range of materials, including hardened steel, titanium, and even exotic alloys.

No mechanical stress

EDM does not produce any mechanical stress on the workpiece, making it ideal for fragile or brittle materials.

No tool wear

EDM does not require the use of cutting tools, meaning there is no tool wear and no need for tool changes during the machining process.

Complex shapes

EDM can produce complex shapes and geometries that may not be possible with traditional machining methods.

High speed

EDM can be a very fast machining process, making it ideal for high-volume production runs.

Available Material For EDM Machining

Aluminum is a highly ductile metal, making it easy to machine. The material has a good strength-to-weight ratio and is available in many types for a range of applications.

- 6061-T6

- 5052

- 1060

- 3003

- 4130

- 4140

- 5083

- 6082

- 5A12

- 7075 T651

- 5052

- 2024

- 1100

- 3004

- 5754

- 6063

- 7050

- 5A02

Brass has desirable properties for a number of applications. It is low friction, has excellent electrical conductivity, and has a golden (brass) appearance. It is commonly used in parts that need a large load.

- Brass C360

- Brass 260

- C932 M07 Bearing Bronze

Copper displays excellent thermal conductivity, electrical conductivity and plasticity. It is also highly ductile, corrosion resistant and can be easily welded.

- Copper

- Copper H62

- Copper H65

- Copper H70

- Copper H80

- Copper H90

- Copper alloy special

Stainless steel features a high-temperature resistant, with good oxidation resistance and corrosion resistance. It is widely used in machine parts, contruction industry parts, etc.

- 303

- 304

- 316L

- 2205 Duplex

- 17-4

- 15-5

- 416

- 420

- 430

- 440C

- 301

Titanium alloy is widely used in automobile industry because of its light weight, high strength and good corrosion resistance.

- Titanium Grade 2

- Titanium 6Al-4V

Special steel is a kind of steel with special composition, special production process, special structure and performance, which can meet special needs. Compared with ordinary steel, special steel has better strength and toughness, physical properties, chemical properties, biocompatibility and technological properties. It is widely used in machinery, automobile, military industry, chemical industry, home appliances, ships, transportation, railway and other fields.

- Tool Steel

- Bearing steel

- Die steel

- High speed steel

- Tungsten steel

- Manganese steel

- Molybdenum steel

- Tungsten chromium steel

Applications

- Tooling components for precision stamping dies, molds, & special machines

- Production of miniature precision components

- High precision components for automation & robotics

- Micro machining components for medical and electronic uses

- Difficult to machine materials including titanium, carbide, exotic alloys, tungsten, MP35N

Get An Accurate Quote For Your Next Projects

Whether your project is complex or simple, whether it is metal or plastic, through our online quotation system, if the algorithm cannot give a reference price, you will get an accurate quotation from our team within 6 hours.