Plastic Injection Molding Services

Use Rapid Manufacture plastic injection molding services to get injection molds and small quantities of high performance plastic parts in 10 days or less.

20+ Years of Experience

Let us help create the injection molded part of your dreams!

Product design and development, complete injection molding and mold making services featuring:

- Plastic product design and development from initial concept to final product

- Over 20 years mold making design experience

- State-of-the-art mold manufacturing at competitive prices

- Focus on creating 3D models

- 35 injection molding machines ranging from 75 tons to 700 tons

- Focus on the science of injection molding technology

Get an online quote for custom plastic molding services

Rapid Manufacture’s custom plastic molding services provide on-demand prototyping and production molding. Our customer-first approach means our manufacturing facility will mold parts the way you need them, at the right price, without having to compromise on design. We provide expert consultation with every injection mold quote and a project manager with every order to move your part from design to production. Our team has extensive experience in various industries, especially medical injection molding and liquid silicone rubber molding.

Why choose Rapid Manufacture's plastic injection molding services?

Our injection molding is able to incorporate many different unique designs that are tailored to our customers’ specifications. We are flexible with your requests and allow you to experience customization at its fullest. Taking a customer-focused approach, we want to ensure you’re completely satisfied with your molding by the time we’re done. Our services are highly efficient and have quick turnaround times, thanks to the fast production our technologies generate. In addition to low wait times, our customers will receive premium, strong components from high-quality injection molding. Although we are not solely limited to medical devices, we take pride in producing reliable medical components that help healthcare workers around the world each day. While the material is strong, it also produces low waste, making our services highly sustainable. Our custom plastic injection molding services are all conducted in clean, white-room environments for controlled and regulated manufacturing.

Quick-Turnaround

While our team brings experience and knowledge, we also know that time is money and will work with you get your product to fruition in a timely manner.

Zero Defects

Rigorous and customized quality control checks are performed on every production run.

Sustainability

We strive to eliminate all waste created by the molding process by reusing and recycling wherever possible.

World Class Capabilities

World Class Capabilities Comprehensive Tooling, Injection Molding Services & More

Injection Molding Services

- Production Molds

- Export Molds

- Family Molds

- Insert Molding

- Overmolding

- Compression Molding

- Rapid Molds

- Mold Manufacturing

- Prototype Molds

Materials

- Plastics

- Thermoplastics

- Polycarbonate

- Polypropylene

- PVC

- Acrylic

- Resin

- Nylon

- Glass-filled Nylon

- ABS

- Thermoplastics Rubber

- Polystyrene

- Low-Density Polyethylene

- Fiber-Reinforced Plastic

- High-Impact Polystyrene

- Acetal/Polyoxymethylene (POM)

- Many Others

Surface Finishes for Plastic Injection Molding

Improve the surface quality of your plastic injection molded parts with superior finishing options Rapid Manufacture offers an extensive list of surface finishes to enhance the aesthetic appeal of your products. These efficient secondary finishes also improve the mechanical quality of prototype and production parts.

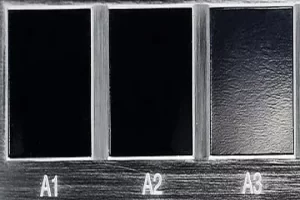

| Glossy | A grade finishes are made using a diamond buffing process and yield shiny and glossy surfaces on injection molded parts. | Learn More>> | |

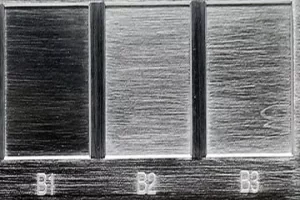

Semi-glossy | B grade finishes use grit sandpaper to produce parts with a slightly rougher finish than grade A parts. Custom molded plastic parts that undergo B grade finishing have a matte surface texture. | Learn More>> | |

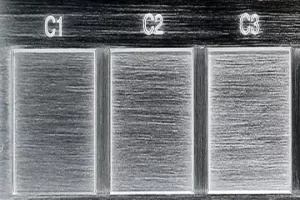

| Matte | C grade finishes use grit sanding stones to produce a rough, uneven surface. Injection plastic parts that undergo C grade finishing have a matte surface texture. | Learn More>> | |

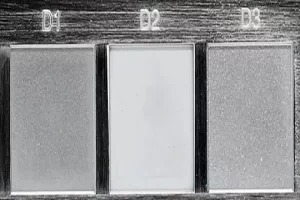

| Textured | D grade finishes use grit and dry glass beads or oxide to produce a very rough textured finish. Depending on the type of material used, products can have a satin or dull finish. | Learn More>> |

What are the most common types of injection molding processes?

The traditional thermoplastic injection molding process can be modified to include processes that help to enhance part quality and part design flexibility. Below are some examples:

Thermoset injection molding

Molding with thermoset materials requires heat or chemical means to cross-link polymer chains.

Overmolding

Overmolding is an injection molding process where one material is molded on top of another.

Gas-assisted injection molding

Inert gas is introduced, at high pressure, into the polymer melt at the end of the injection phase of molding.

Co-injection & Bi-injection molding

Injection of two different materials using either the same or different injection locations.

Microcellular injection molding

Use of physical blowing agent, chemical blowing agent (CBA), or mold core-back process to trigger foaming of polymer inside the mold.

Powder injection molding (PIM)

Forming technique for producing small components using powders, typically ceramics (CIM) or metals (MIM), and binding agents

We Work With Nearly All Industries

Rapid Manufacture’s plastic injection molding service is perfect for addressing the various demands of different industries, including the automotive, medical, and consumer goods fields.